Operating problems, causes and remedies

Customer checklist

74 Item No.: 099-004934-EWM01

9 Operating problems, causes and remedies

9.1 Customer checklist

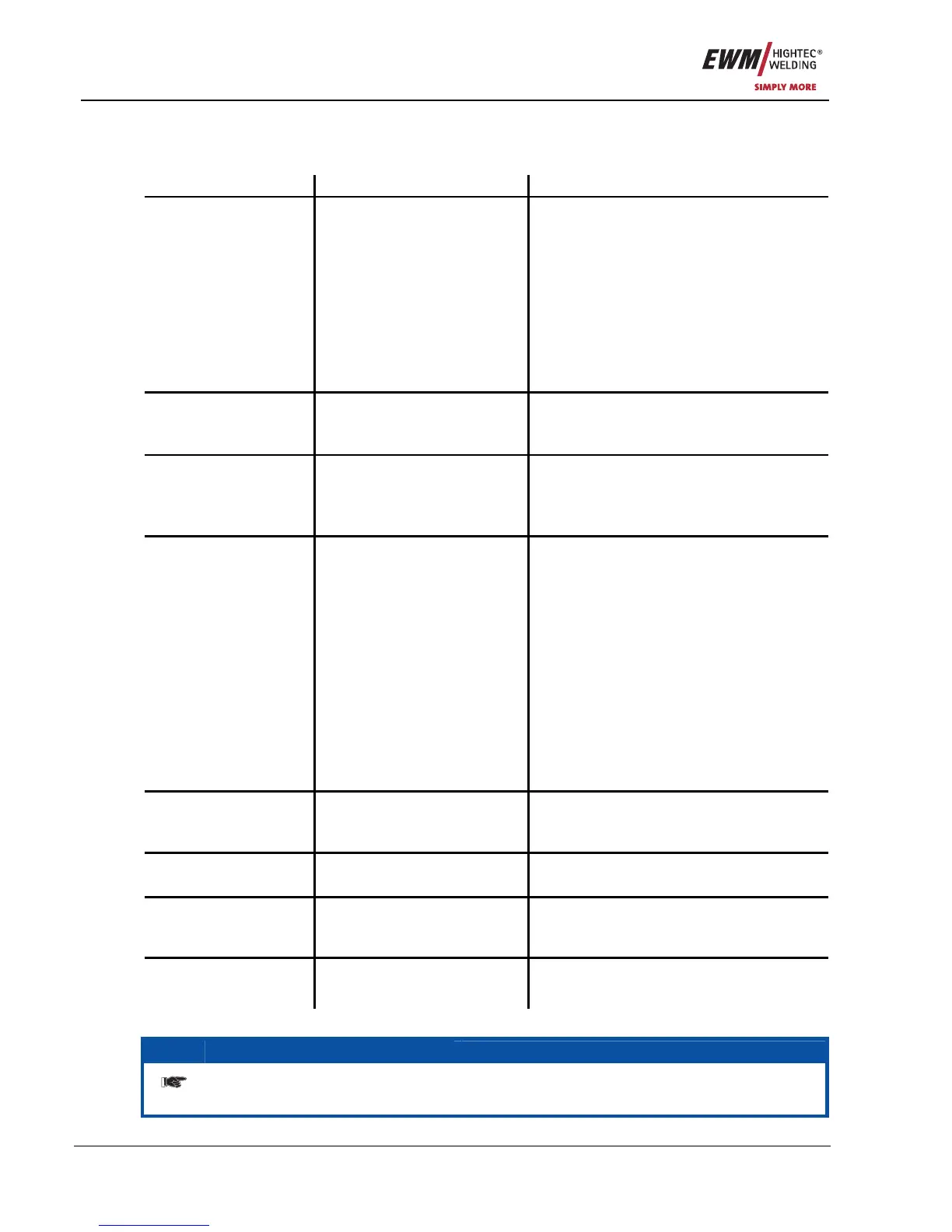

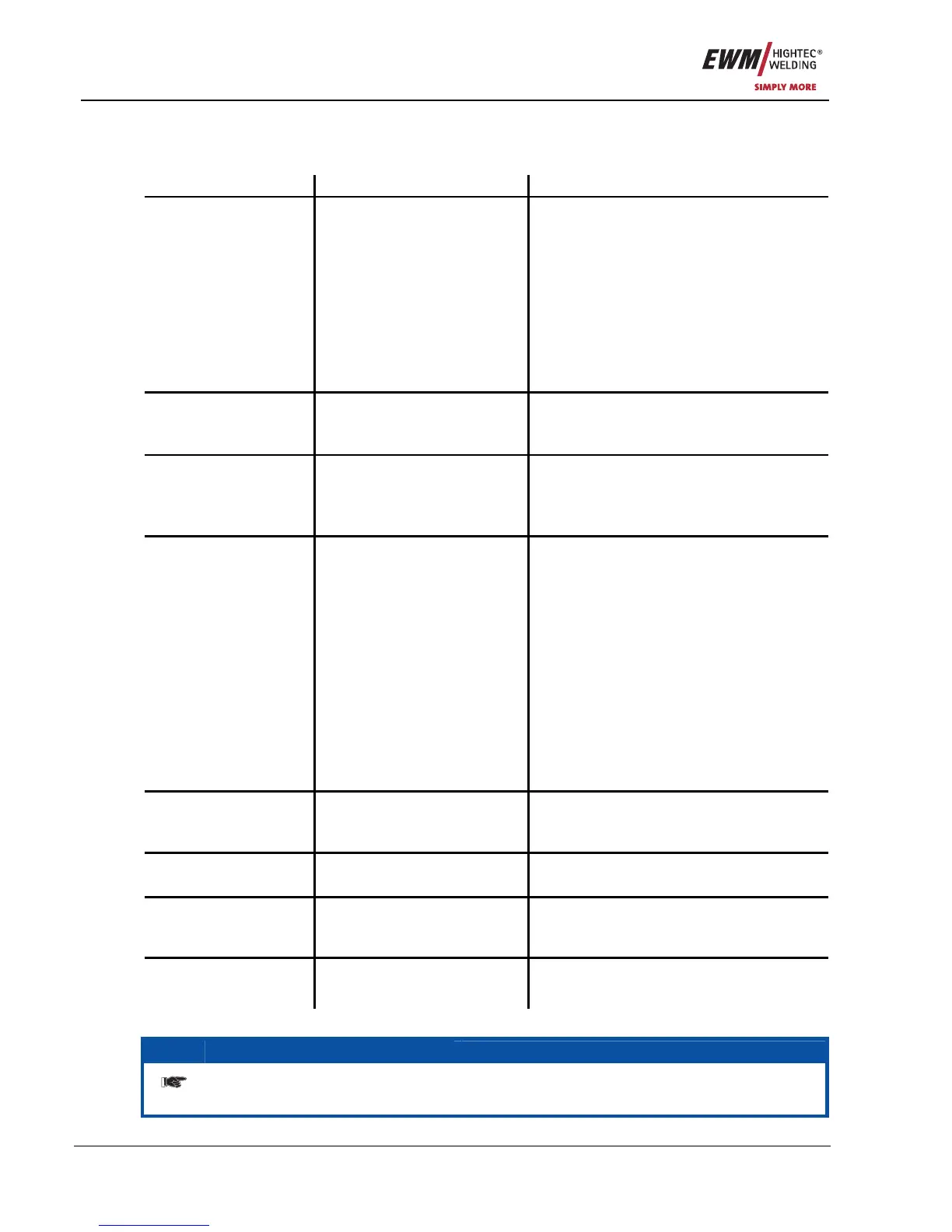

Error Possible cause Remedy

Spatter has blocked the

contact nozzle

Clean nozzle, spray on separating agent

Feed roller is slipping Check contact pressure roller. Check for

wear and tear and replace if necessary

Wire feed motor is not turning

over

Check automatic cut-out on the wire feed

motor

Wire bent Unfasten contact nozzle, cut off wire after

bent section

Wire coil brake too strong Set coil brake correctly

No wire feed

Torch defective Replace

Core or nozzle blocked Clean, replace if necessary Loop in wire

Tube package bent too much Stretch out tube package

Wire feed coils blocked or

damaged

Clean, replace if necessary

Wire coil brake too strong Set coil brake correctly

Wire feed irregular

Contact nozzle too small Check, replace if necessary

Incorrect shielding gas setting Correct: Rule of thumb "Wire diameter *10 =

flow in l/min"

Gas cylinder empty Change

Electrode is projecting too far

forwards

Move torch closer to weld seam

Air current Shield welding area

Poor wire quality Use high quality wire, store in a dry and

clean location.

Very dirty workpiece Clean workpiece first

Local overheating of the

workpiece

Include occasional pauses in welding to

allow the workpiece to cool down.

Weld seam porous

Gas line is drawing in air Check seal tightness on lines, seal / replace

if necessary.

No mains voltage Check the mains fuses, replace as

necessary

Machine will not switch

on

Power source faulty Contact service

Blow effect Connect workpiece line more appropriately Strong spatter

No gas Set gas quantity to match the application

Workpiece line has no or poor

contact

Check connection No welding current

Power source overheating Allow machine to cool down

Wire feed or gas valve

faulty

Electronic control Check line connections, replace electronics

if necessary. Contact service

9.2 Resetting the control (Reset all)

NOTE

M2.40 control

The first action should always be to check and if necessary correct the machine type setting.

Loading...

Loading...