FX16 Master Controller Technical Bulletin

60

Digital Outputs

The FX16 Master Controller features nine digital outputs. The digital

outputs are available in two hardware configurations with 9 relays, or

4 relays and 5 triacs. See I/O Technical Details for the complete FX16

Master Controller I/O table.

The digital output objects provide the interface between the hardware

digital output channels and the control application. You can set the

parameters in FX Builder.

You can override a digital output and its value modified via a

supervisory system if the digital output and its value were configured in

the control application.

Using FX Builder, you can configure the Digital Output objects to

provide the output types in Table 19.

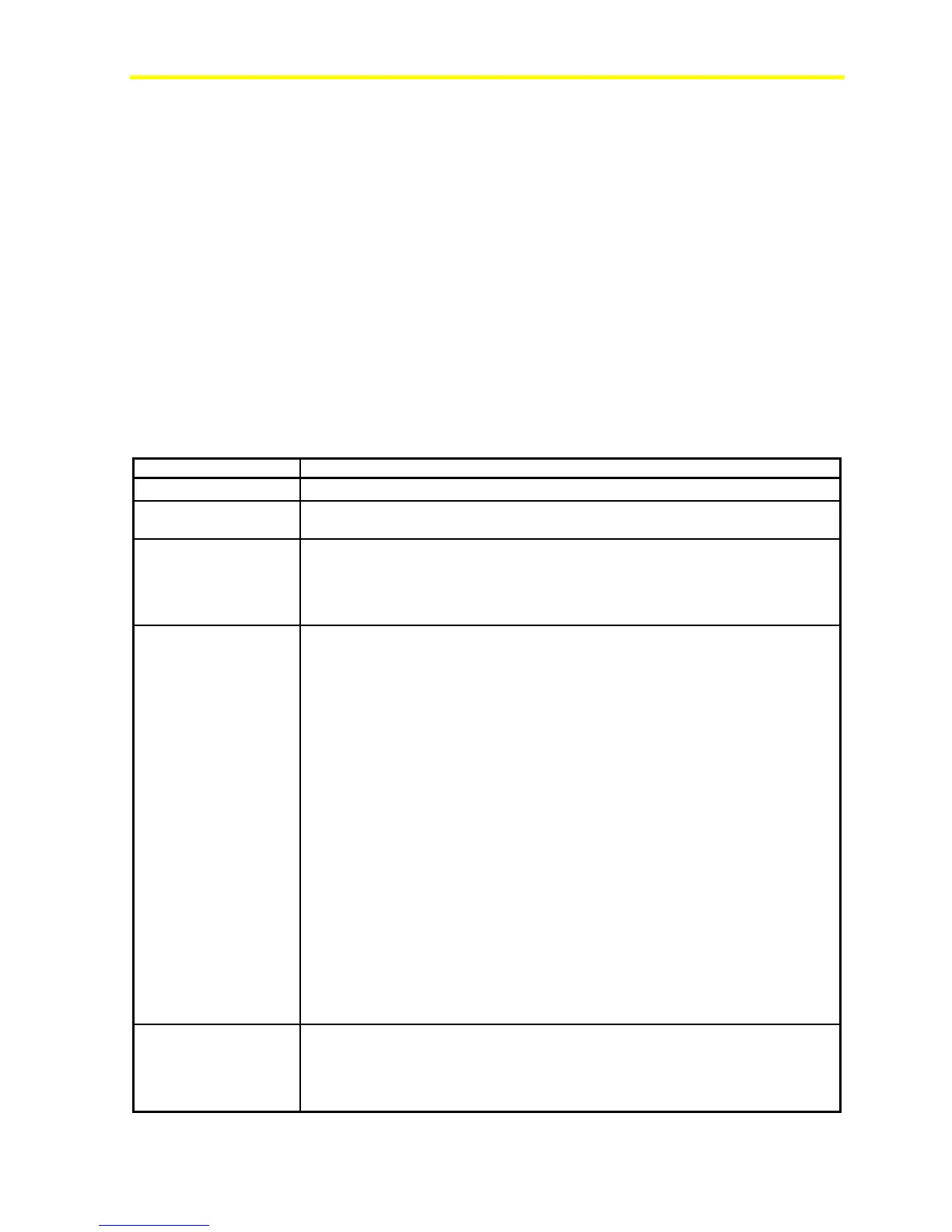

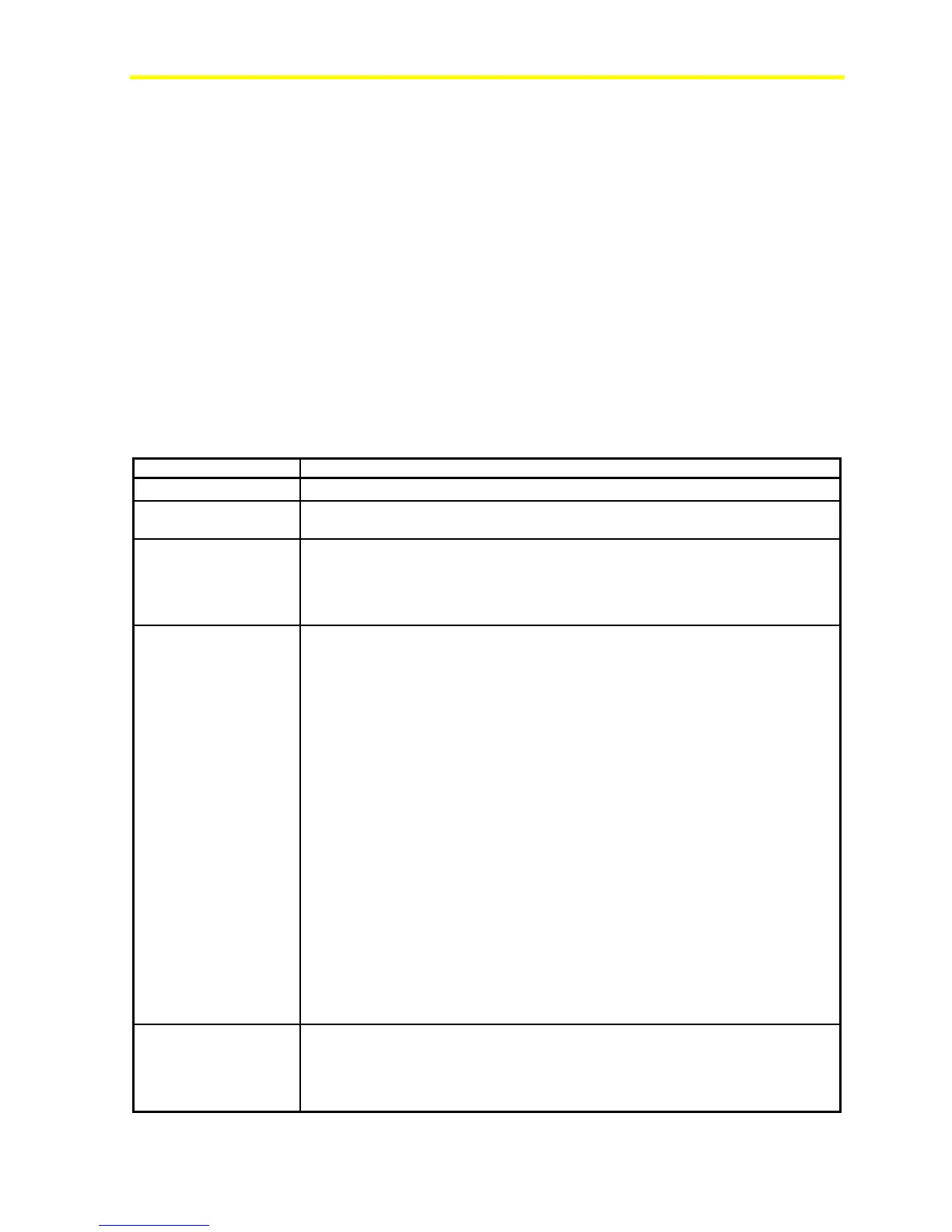

Table 19: Output Types

Output Description

On/Off Output

Commands the triac or relay to switched on or off depending on the input request.

Hermetic Compressor

Output

Features all the functions required to drive a hermetic compressor. This output type

provides the logic, interlocking, and timing features required for such application.

Duration Adjusting

Type (DAT) Output

Commands the DO (typically a triac) to drive on or off with a time based duty cycle

proportional to the numeric input request. You may set a minimum On/Off time to

avoid very short On pulses when the value is close to the low range value (Output at

0%) and very short Off pulses when the value is close to the high range value

(Output at 100%).

Position Adjusting

Type (PAT),

Incremental Control

Output

You can use a pair of triacs to drive a synchronous reversible electric actuator in one

of the two directions in response to a change in the numeric input request.

A PAT output gives modulating control by using the configured actuator full-stroke

(fully open to fully close) time to drive the actuator for a part of that time base in

proportion to the change in the controlling numeric input. For example, for a

100-second actuator to achieve 40% open, the actuator runs 40 seconds from the

fully closed position.

You may set a dead band, in percent of full-stroke time, to avoid driving the actuator

for very small changes in the output signal. This reduces unnecessary wear on the

drive mechanism.

The PAT object requires two digital output channels, typically triacs. One triac is

switched on when the output must increase. The other triac is switched on when the

output must decrease. The polarity of the PAT can change the increasing and

decreasing physical channels without rewiring.

At 0 or 100% position, the duration of switching increases by a configurable value

(ResyncAmount). This ensures the valve or other controlled device is completely at

its end position. If the estimated position remains fixed at 0 or 100% for a time equal

to a configurable period (typically 2 hours), a synchronization action occurs according

to the ResyncAmount configurable parameter.

If the output remains in a fixed position for more than another configurable period, the

PAT output applies the anti-sticking function (if enabled) to exercise the device and

the drive mechanism. This is particularly useful for water valves that require regular

activity of the inner parts to keep them free to move.

Damper PAT Output

Damper PAT Output type is identical to the PAT with the exception that it does not

increase the duration of the switching when 0 or 100% is reached. This avoids the

unstable control of air systems and implements the synchronization action as

configured. This output does not implement the anti-sticking function as damper

drives are not typically subject to this problem.

Loading...

Loading...