4. Maintenance

USE AND MAINTENANCE MANUAL CHAPTER 4

MAINTENANCEXEF 250 - Rev01 / 2020

72

1

2

5

6

1

3

2

4

FWD

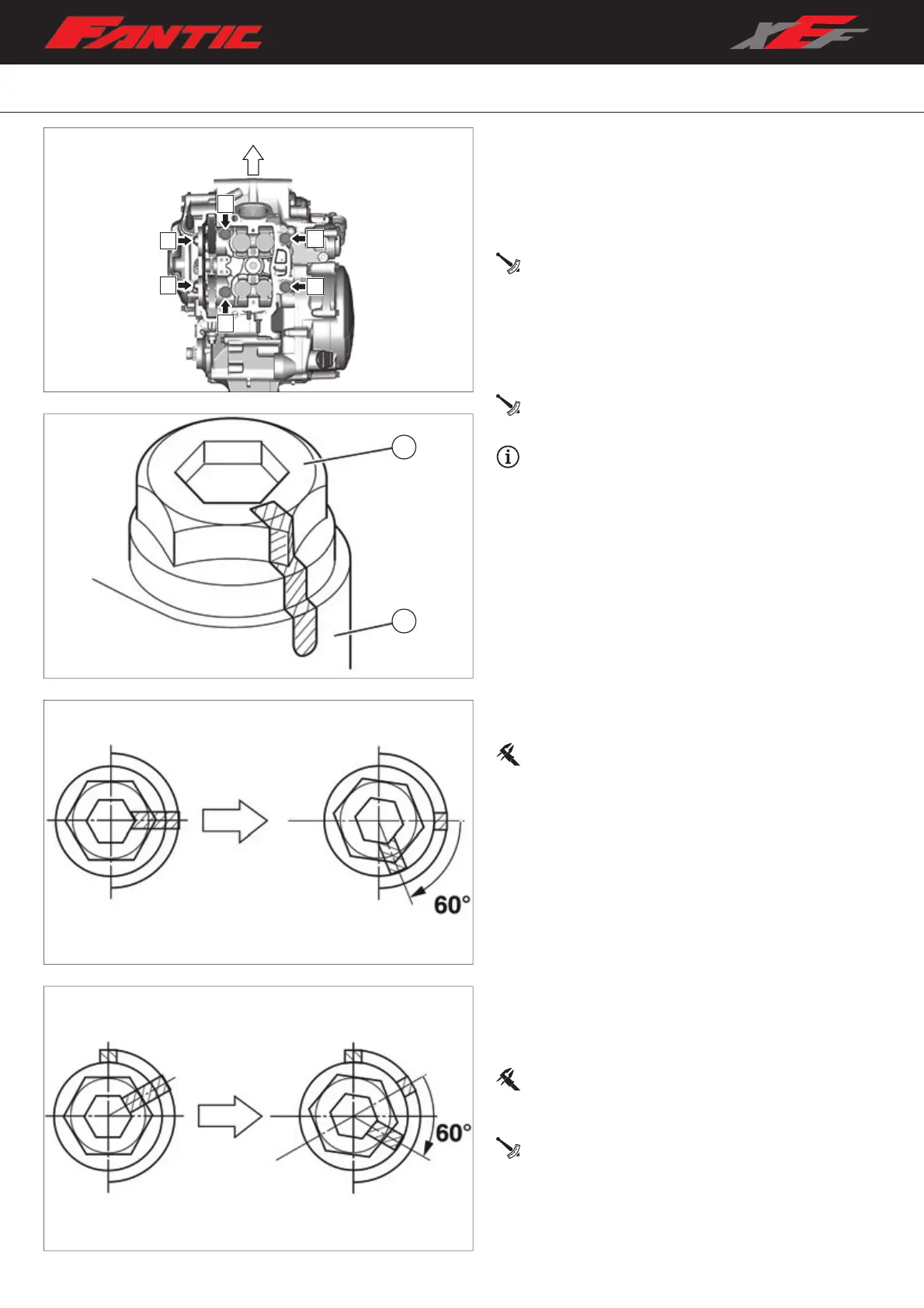

– Tighten each bolt by turning it 60° with respect to the initial

reference, following the 1st Phase tightening order;

Head bolts “1” – “4”:

Specified angle = 60°

4th Phase

– Mark a second reference between the bolt and the head,

then tighten each bolt by a further 60° following the

tightening order of the 1st Phase;

Head bolts “1” – “4”:

Specified angle = 60°

– Tighten the nuts “5” and “6” to the specified torque.

Nuts “5” – “6”:

10 Nm (1.0 m•kg, 7.4 ft•lb)

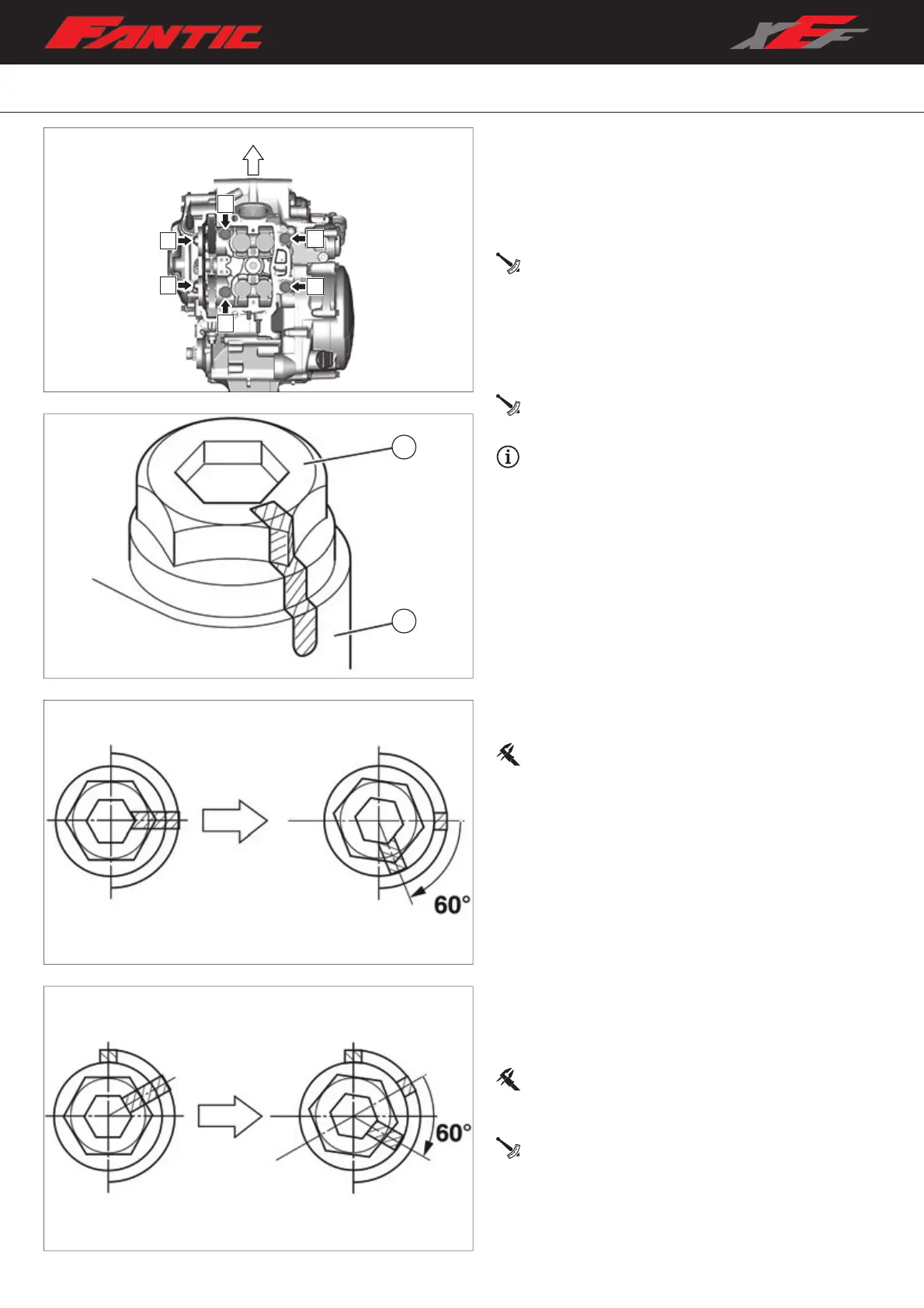

The head bolts tightening must be completed in four

steps, as described below:

1st Phase

– Tighten the head bolts to the specified torque by

performing the operation in two/three steps, following the

diagram shown in the figure.

Head bolts “1” – “4”:

30 Nm (3.0 m•kg, 22 ft•lb)

2nd Phase

– Remove a single bolt, following the tightening order;

– Apply molybdenum disulphide grease again to the thread

and contact surface of the bolt and washer;

– Tighten the bolt to the specified torque;

Head bolts “1” – “4”:

15 Nm (1.5 m•kg, 11 ft•lb)

Perform the 2nd Phase operations one bolt at a time.

Remove the bolts in the order used for tightening,

then tighten them according to the new tightening

torque.

3rd Phase

– Using a marker pen, mark a reference between bolt “1” and

head “2”;

Loading...

Loading...