FT-70/75 Fill Level Inspectors Operator’s Guide

1-4

Fill Level Inspection Basics

The FT-70/75 Fill Level Inspection systems utilizes a Container

Radiation Profile Comparison Principle to create a radiation finger-

print of the container.

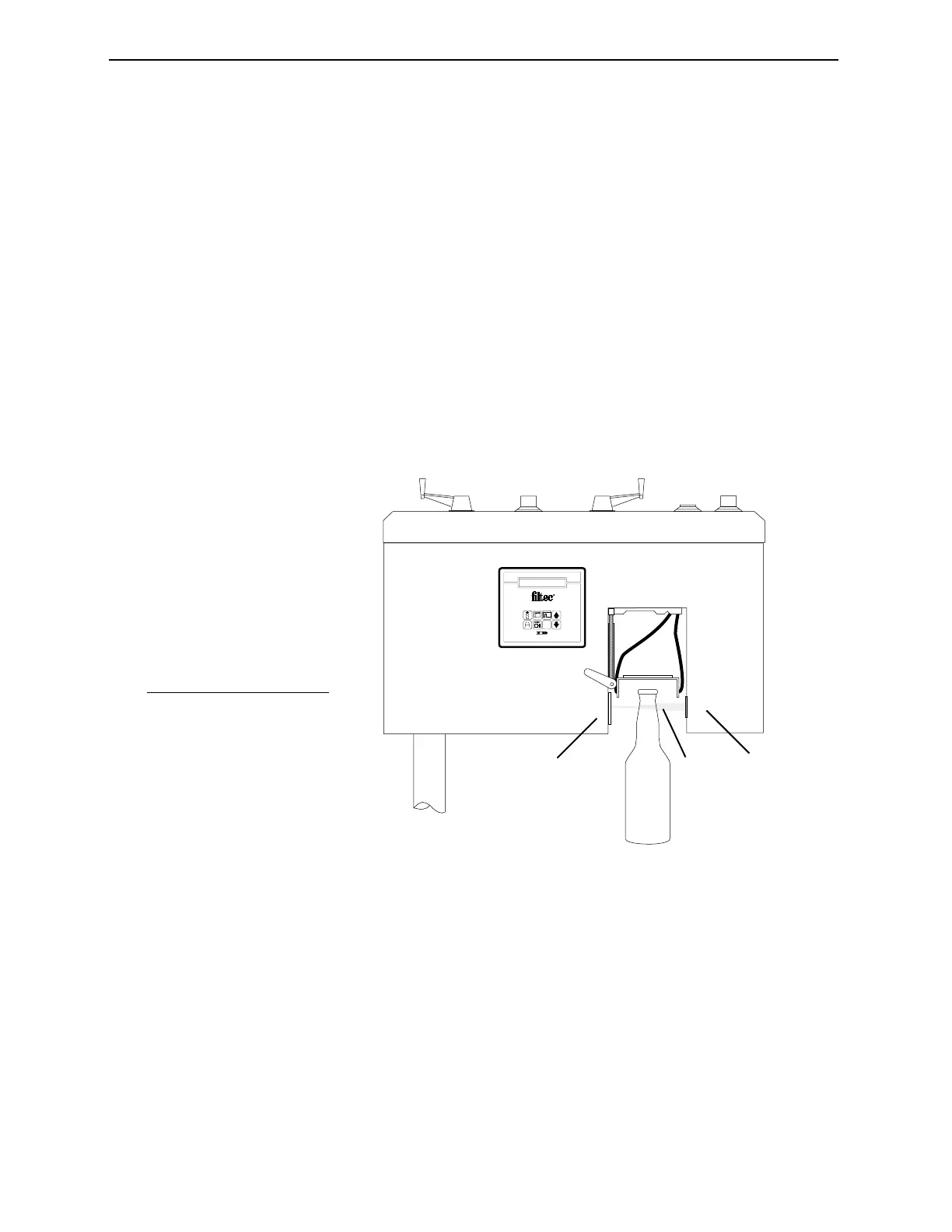

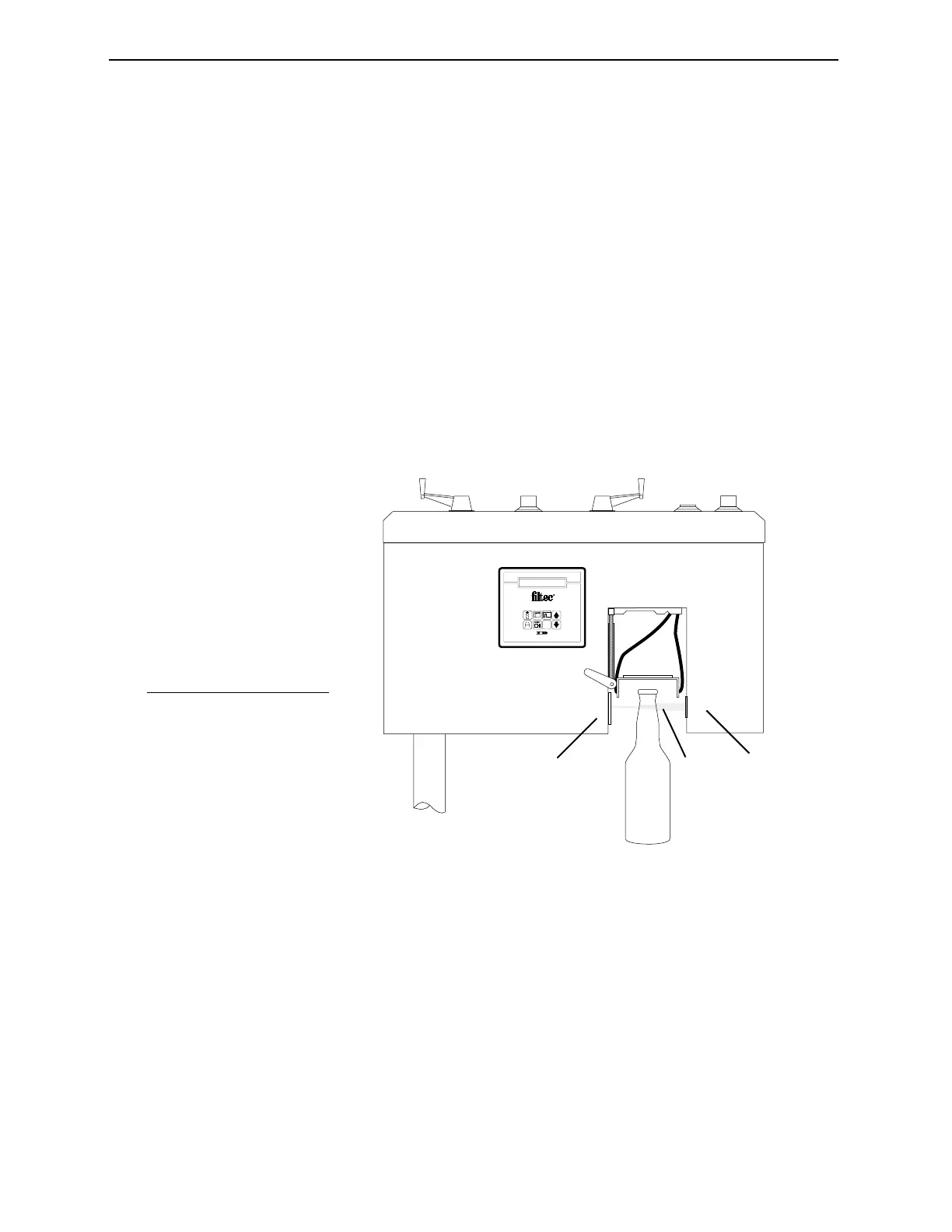

To create a radiation profile a x-ray beam is directed through the

container. Some of the radiation is blocked by the container

material and container’s contents while the remaining x-rays

emerge from the opposite side of the container where they are

measured by an x-ray detector.

The amount of radiation measured is the containers Radiation

Profile, or fingerprint, which is then compared against a

Master

Container Profile

.

Figure 1-2.

Scanning the container.

To allow for slight variances in the fill level an Underfill Threshold

and Overfill Threshold are determined (both for the FT-75 and one

or the other for the FT-70). These thresholds form the tolerance

range for deviation from the Master Profile. This tolerance range

between the thresholds is called the Target Zone. Any container

with an x-ray count that falls below the Underfill Threshold is

rejected as an underfill and any container with a X-ray count that

rises above the Overfill Threshold is rejected as an overfill.

?

6

INDUSTRIAL DYNAMICS

Torrance, California USA

MODEL FT-50

FILL LEVEL INSPECTOR

4

3

5

1

2

1

32

No. Description

1 X-ray Source

2 X-ray Beam

3 X-ray Detector

Industrial Dynamics Company, Ltd. Document 40274-0600

Loading...

Loading...