Instruction Manual

D103409X012

Maintenance and Troubleshooting

May 2013

110

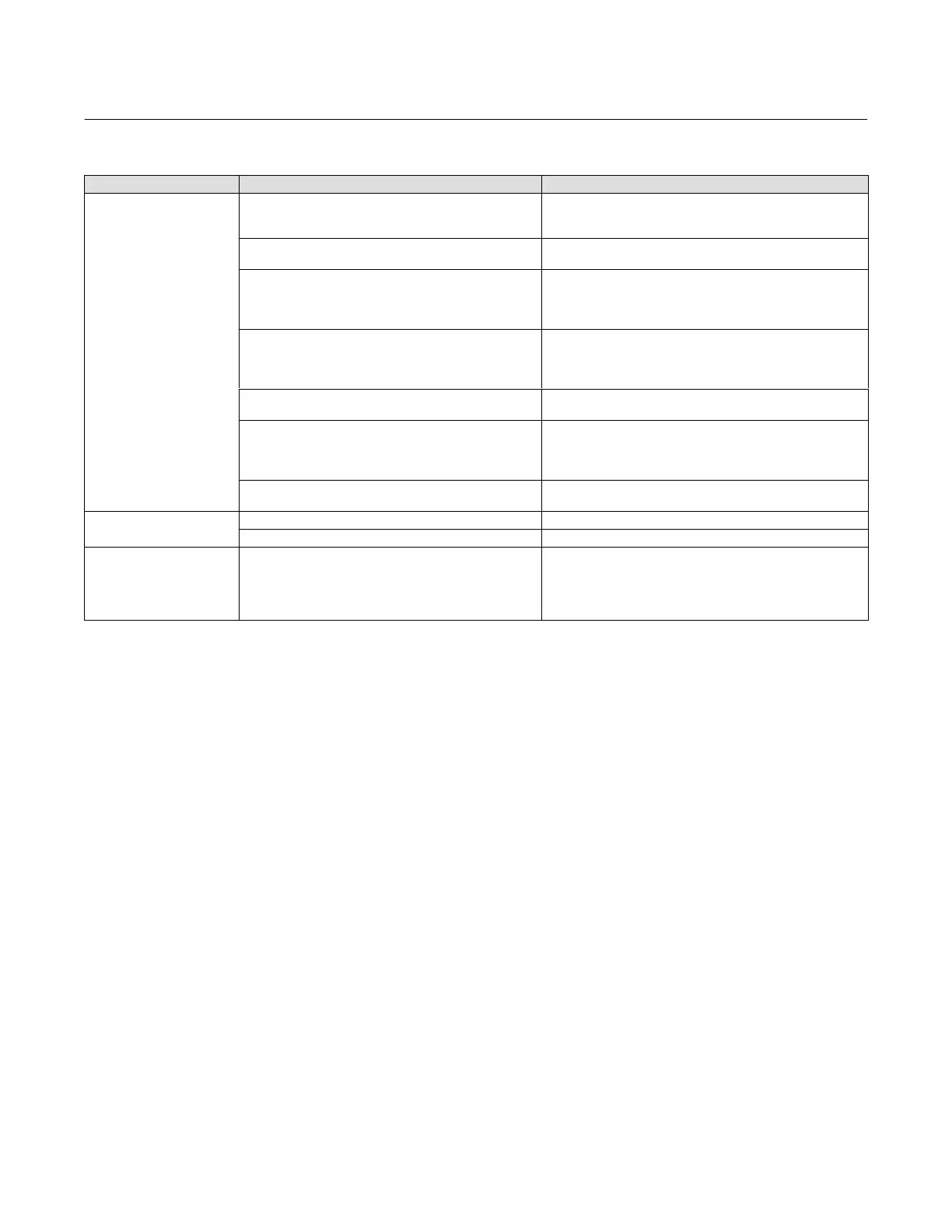

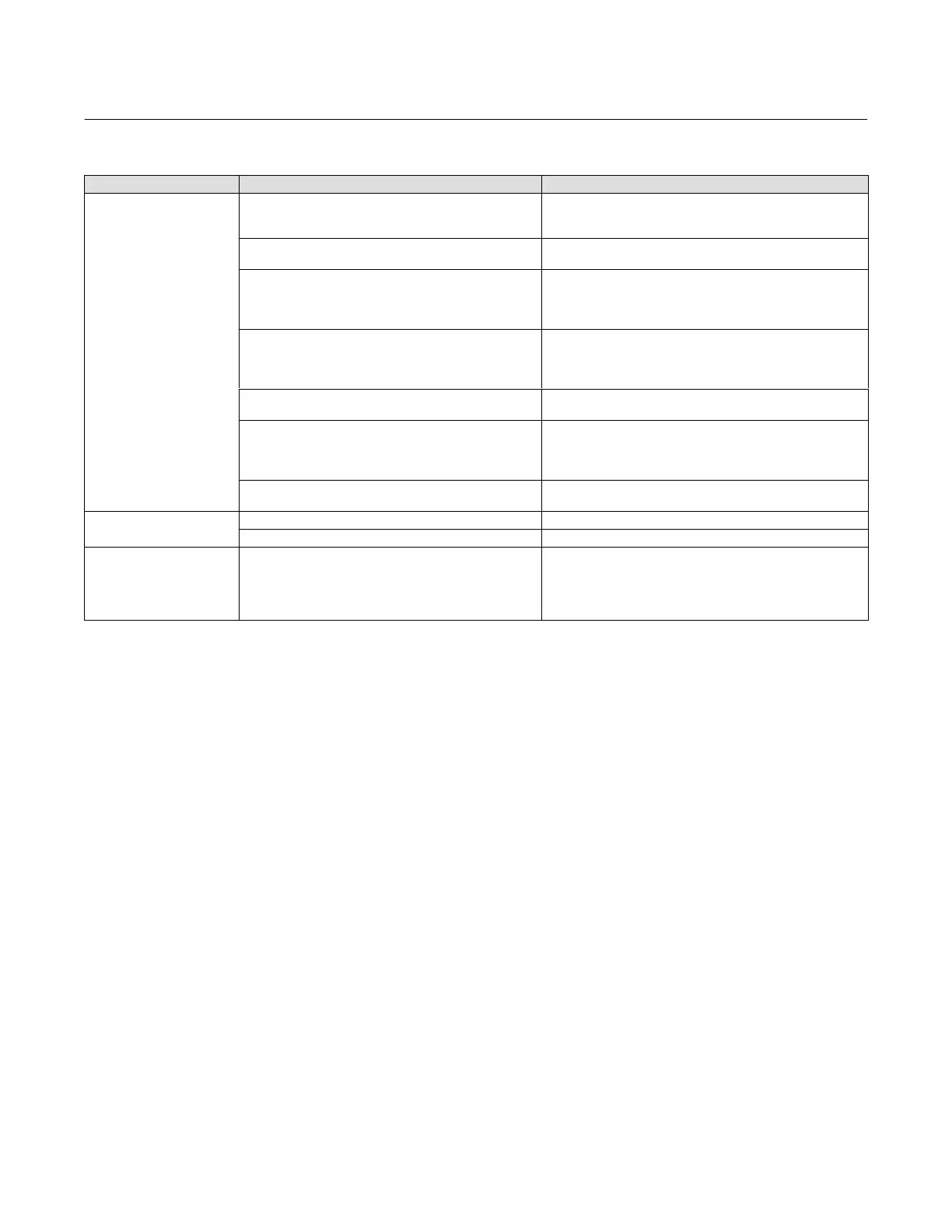

Table 7‐3. Instrument Troubleshooting (Continued)

ActionPossible CauseSymptom

3b. Restricted pneumatic passages in I/P converter. 3j. Check screen in I/P converter supply port of the module base.

Replace if necessary. If passages in I/P converter restricted,

replace I/P converter.

3c. O‐ring(s) between I/P converter ass'y missing or hard

and flattened losing seal.

3k. Replace O‐ring(s).

3d. I/P converter ass'y damaged/corroded/clogged. 3l. Check for bent flapper, open coil (continuity), contamination,

staining, or dirty air supply. Coil resistance should be between

1680 ‐ 1860 ohms. Replace I/P assembly if damaged, corroded,

clogged, or open coil.

3e. I/P converter ass'y out of spec. 3m. I/P converter ass'y nozzle may have been adjusted. Verify

drive signal (55 to 80% for double‐acting; 60 to 85% for

single‐acting) with the valve off the stops. Replace I/P converter

assembly if drive signal is continuously high or low.

3f. Defective module base seal. 3n. Check module base seal for condition and position. If

necessary, replace seal.

3g. Defective relay. 3p. Depress relay beam at adjustment location in shroud, look

for increase in output pressure. Remove relay, inspect relay seal.

Replace relay seal or relay if I/P converter assembly is good and

air passages not blocked. Check relay adjustment.

3h. Defective 67CFR regulator, supply pressure gauge

jumps around.

3q. Replace 67CFR regulator.

4. ValveLink diagnostic tests

provide erroneous results.

4a. Defective pressure sensor. 4a. Replace PWB.

4b. Pressure sensor O‐ring missing. 4b. Replace O‐ring.

5. Field Communicator does

not turn on.

5a. Battery pack not charged. 5a. Charge battery pack.

Note: Battery pack can be charged while attached to the Field

communicator or separately. The Field Communicator is fully

operable while the battery pack is charging. Do not attempt to

charge the battery pack in a hazardous area.

Loading...

Loading...