Instruction Manual

D103409X012

Maintenance and Troubleshooting

May 2013

109

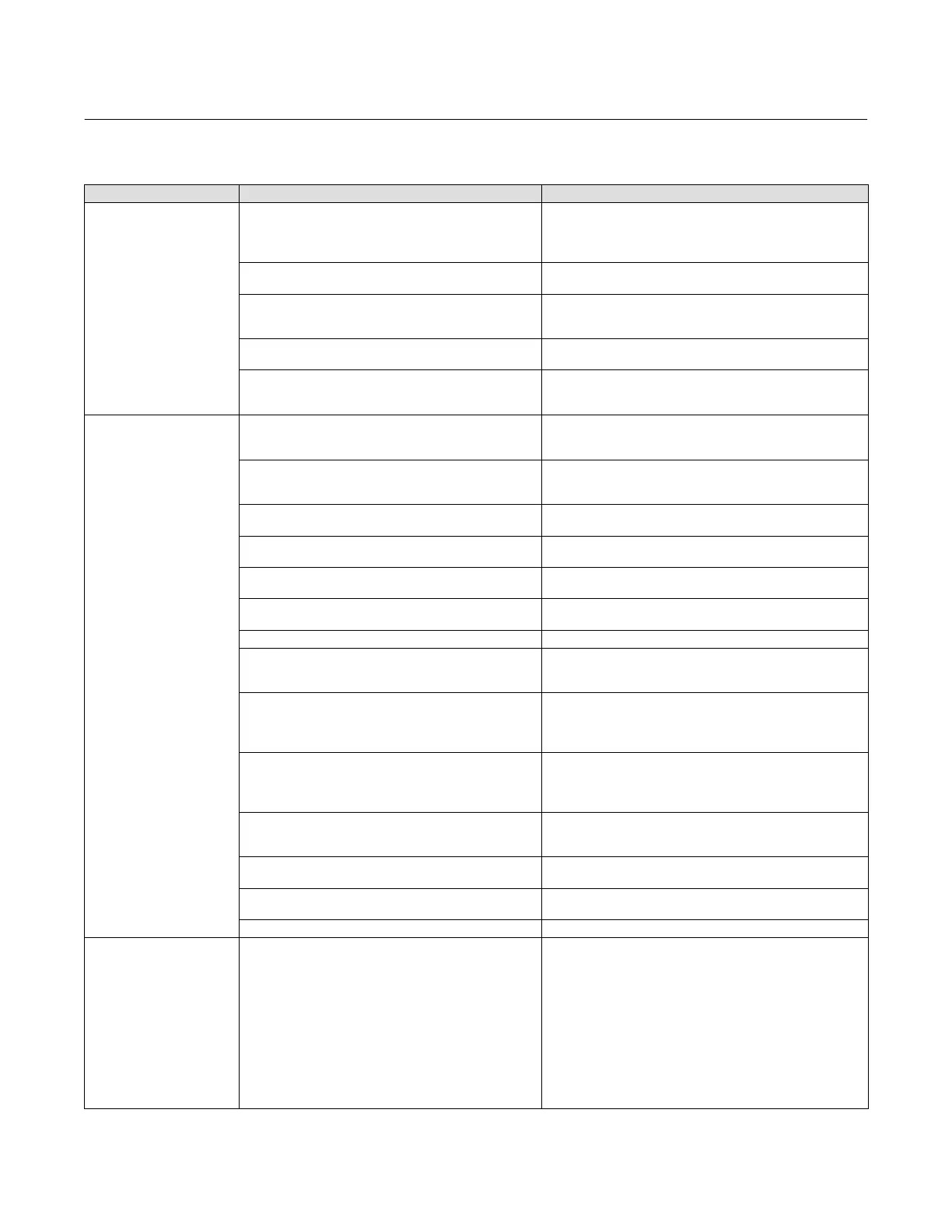

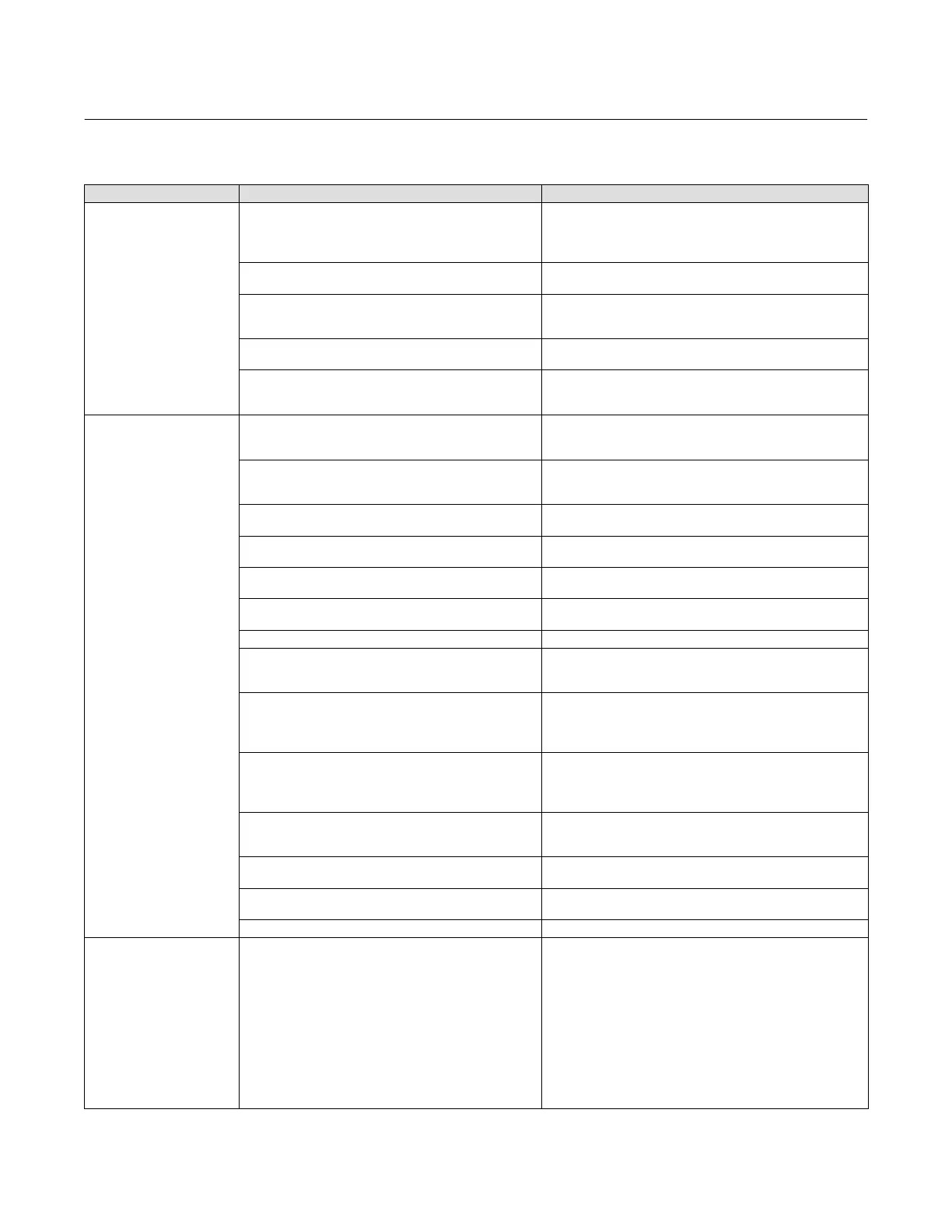

Table 7‐3. Instrument Troubleshooting

Symptom Possible Cause Action

1. Analog input reading at

instrument does not match

actual current provided.

1a. Control mode not Analog. 1a. Check the control mode using the Field Communicator. If in

the Digital or Test mode, the instrument receives its set point as

a digital signal. Control is not based on input current. Change

Control Mode to Analog.

1b. Low control system compliance voltage. 1b. Check system compliance voltage (see Wiring Practices in

the Installation section.

1c. Instrument shutdown due to self test failure. 1c. Check instrument status using the Field Communicator (see

Viewing Instrument Status in the Viewing Device Information

section).

1d. Analog input sensor not calibrated. 1d. Calibrate the analog input sensor (see Analog Input

Calibration in the Calibration section).

1e. Current leakage. 1e. Excessive moisture in the terminal box can cause current

leakage. Typically the current will vary randomly if this is the

case. Allow the inside of the terminal box to dry, then retest.

2. Instrument will not

communicate.

2a. Insufficient Voltage Available. 2a. Calculate Voltage Available (see Wiring Practices in the

Installation section). Voltage Available should be greater than or

equal to 11 VDC.

2b. Controller output Impedance too low. 2b. Install a HART filter after reviewing Control System

Compliance Voltage requirements (see Wiring Practices in the

Installation section).

2c. Cable capacitance too high. 2c. Review maximum cable capacitance limits (see Wiring

Practices in the Installation section).

2d. HART filter improperly adjusted. 2d. Check filter adjustment (see the appropriate HART filter

instruction manual).

2e. Improper field wiring. 2e. Check polarity of wiring and integrity of connections. Make

sure cable shield is grounded only at the control system.

2f. Controller output providing less than 4 mA to loop. 2f. Check control system minimum output setting, which should

not be less than 3.8 mA.

2g. Disconnected loop wiring cable at PWB. 2g. Verify connectors are plugged in correctly.

2h. PWB DIP switch not set properly. 2h. Check for incorrect setting or broken DIP switch on the back

of the PWB. Reset switch or replace PWB, if switch is broken. See

table 7‐2 for switch setting information

2j. PWB failure. 2j. Use a 4-20 mA current source to apply power to the

instrument. Terminal voltage across the LOOP+ and LOOP-

terminals should be 9 to 10.5 VDC. If the terminal voltage is not

9 to 10.5 VDC, replace the PWB.

2k. Polling address incorrect. 2k. Use the Field Communicator to set the polling address (refer

to the Detailed Setup section). From the Utility menu, select

Configure Communicator > Polling > Always Poll. Set the

instrument polling address to 0.

2l. Defective terminal box. 2l. Check continuity from each screw terminal to the

corresponding PWB connector pin. If necessary, replace the

terminal box assembly.

2m. Defective Field Communicator or ValveLink

modem cable.

2m. If necessary, repair or replace cable.

2n. ValveLink modem defective or not compatible

with PC.

2n. Replace ValveLink modem.

2p. ValveLink hardlock defective or not programmed. 2p. Replace if defective or return to factory for programming.

3. Instrument will not

calibrate, has sluggish

performance or oscillates.

3a. Configuration errors. 3h. Verify configuration:

If necessary, set protection to None.

If Out of Service, place In Service.

Check:

Travel Sensor Motion

Tuning set

Zero control signal

Feedback Connection

Control mode (should be Analog)

Restart control mode (should be Analog)

Loading...

Loading...