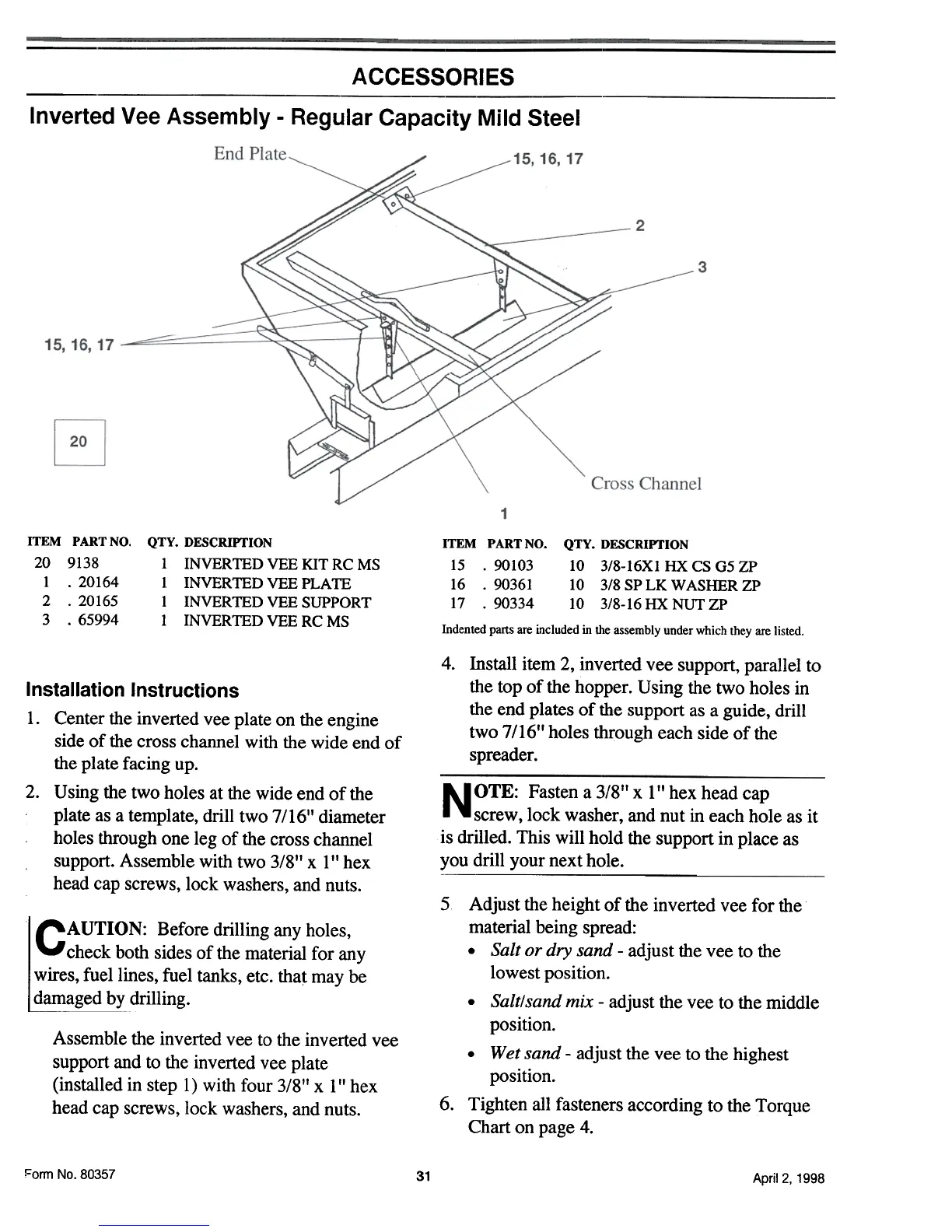

ACCESSORIES

Inverted Vee Assembly -Regular Capacity Mild Steel

ITEM PART NO.

20 9138

1 .20164

2 .20165

3 .65994

QTY. DESCRIYfION

1 INVERTED VEE KIT RC MS

1 INVERTEDVEEPLATE

1 INVERTED VEE SUPPORT

1 INVERTED VEE RC MS

ITEM PART NO. QTY. DESCRIPTION

15 .90103 10 3/8-16X1 HX CS 05 ZP

16 .90361 10 3/8 SP LK WASHER ZP

17 .90334 10 3/8-16 HX NUT ZP

Indented parts are included in the assembly under which they are listed.

4. Install item 2, inverted vee support, parallel to

the top of the hopper. U sing the two holes in

the end plates of the support as a guide, drill

two 7/1611 holes through each side of the

spreader.

Installation Instructions

1. Center the inverted vee plate on the engine

side of the cross channel with the wide end of

the plate facing up.

2. U sing the two holes at the wide end of the

plate as a template, drill two 7/161' diameter

holes through one leg of the cross channel

support. Assemble with two 3/8" x 1 " hex

head cap screws, lock washers, and nuts.

NOTE: Fasten a 318'1 x 1" hex head cap

screw, lock washer, and nut in each hole as it

is drilled. This will hold the support in place as

you drill your next hole.

5

l§~~!AUTION: Before drilling any holes,

check both sides of the material for any

wires, fuel lines, fuel tanks, etc. tha~ may be

damaged by drilling.

Assemble the inverted vee to the inverted vee

support and to the inverted vee plate

(installed in step I) with four 3/811 x 111 hex

head cap screws, lock washers, and nuts.

6.

Adjust the height of the inverted vee for the

material being spread:

.Salt or dry sand -adjust the vee to the

lowest position.

.Salt/sand mix -adjust the vee to the middle

position.

.Wet sand -adjust the vee to the highest

position.

Tighten all fasteners according to the Torque

Chart on page 4.

Form No.80357

31

April 2, 1998

Loading...

Loading...