F3D3 Series Service Manual Refrigeration / Section 4.4.1

Questions? Call Franke Technical Support Group For Your Area. Copyright 2012 Franke, Inc. All rights reserved.

4.4.1 Checking For Leaks Using Nitrogen

F3D3 & F3D3S Models ONLY

If a leak is very small or intermittent and difficult to detect, the

system can be leak-checked by pressurizing with nitrogen.

NOTE: Follow this procedure before checking for a leak in the

cold wall Evaporator. See Section 4.4.2 for Evaporator.

1) Separate the high side from the low side by cutting the

copper lines going into the walls of the freezer cabinet.

2) Pinch and solder the cut lines on the high side or add

additional access fittings to pressurize the refrigeration

system except the evaporator.

3) To use an electronic leak detector, add a few ounces of

R-404A to act as a tracer gas.

4) Pressurize the high side and the compressor with

nitrogen through access fittings to an equalized

maximum of 150 PSIG [10.5 Bar]. IMPORTANT: A test

pressure higher than 150 PSIG is not recommended for

the compressor shell. (See Photo 3)

5) Use an electronic leak detector or application of a soap

solution to locate any and all leaks. Places to check

carefully include:

The pressure relief valve

Fittings and seams on the receiver tank

All solder joints

Access fittings (with and without caps on)

6) If a leak cannot be found and the test pressure appears

to be steady, record the test pressure, plus room

temperature and cabinet inside wall temperature.

7) Leave the unit pressurized for 24 hours.

PSIG/Bar PSIG/Bar

°F / °C °F / °C

°F / °C °F / °C

8) Record the pressures and temperatures again at the end

of the test period. A pressure drop of more than 10 PSIG

[.7 Bar] within 24 hours indicates that there is a leak

somewhere and a more careful search is required.

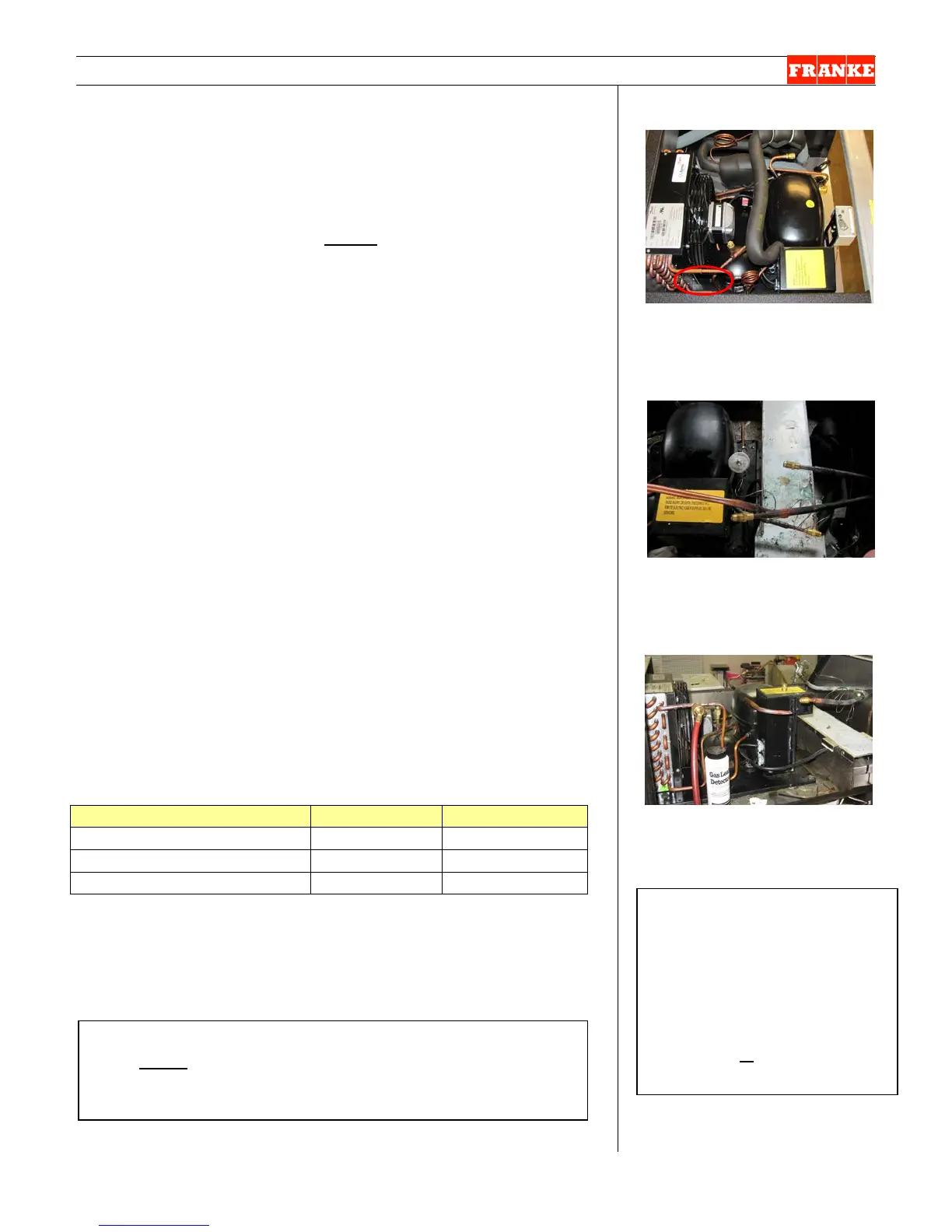

[Photo 1] – from above-right

Cut the copper lines going down

into the freezer cabinet.

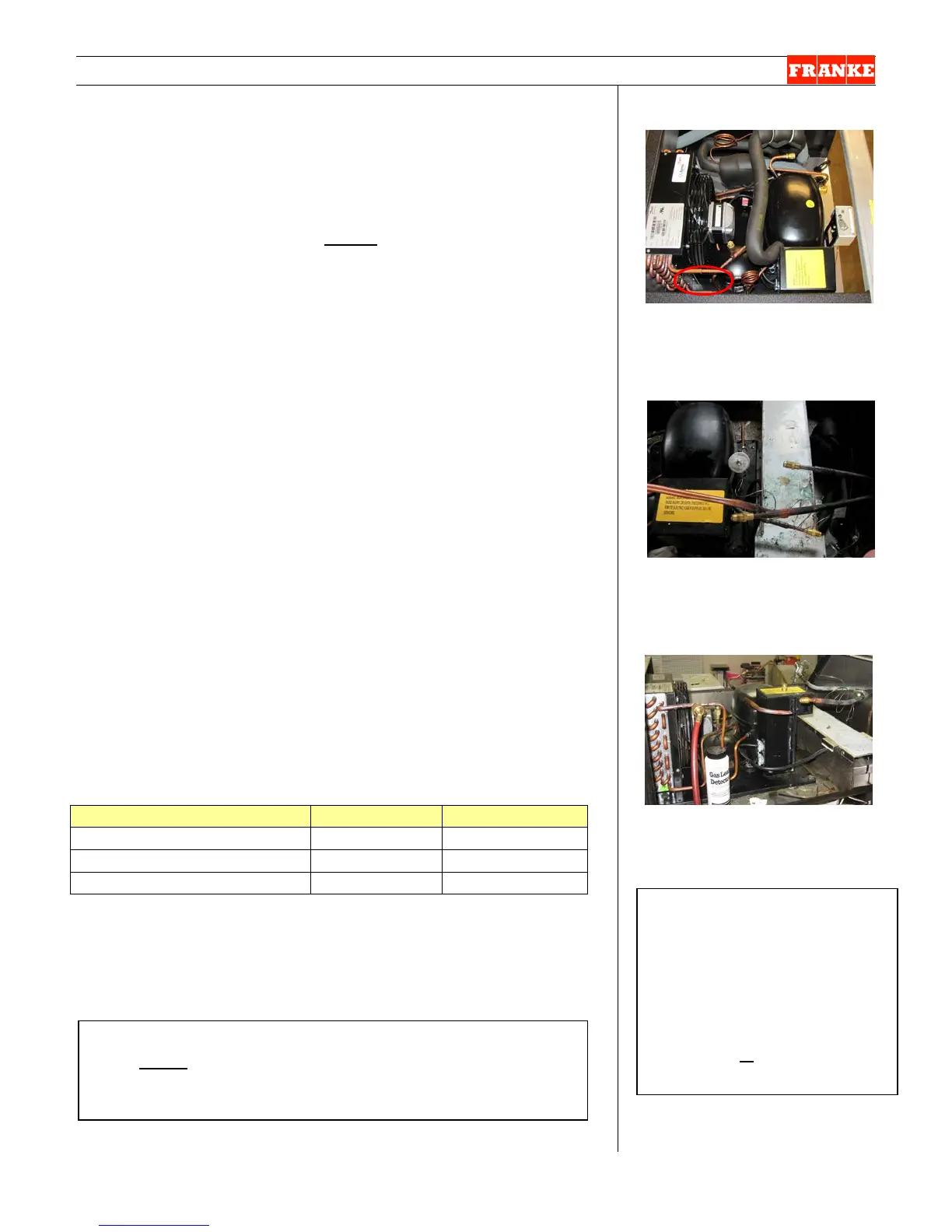

[Photo 2] – from right side

Pinch & solder high side lines or

use access fittings on both high

& low (evaporator) side.

[Photo 3]

Add a few ounces of R-404A

refrigerant & pressurize to 150

PSIG [10.5 Bars] with nitrogen.

Rev. 1 11/2012

Tubing cutter

Crimping tool or pliers

Two-four access fittings

Torch, solder, etc.

Manifold Refrigeration

Pressure Gauge

Electronic Refrigeration Leak

Detector or

Liquid leak-detection soap

NOTE: Do not use an electronic leak detector to locate

leaks inside the freezer evaporator housing. The foam

insulation used inside the evaporator housing contains

HFCs, which will generate false readings.

Loading...

Loading...