Step 1: Site Planning

● The cable inlets and outlets are located on the four side panels of aGate: upper, lower, left and rear. The following scenarios

illustrate different configurations accounting for variations in the existing residential wiring layout.

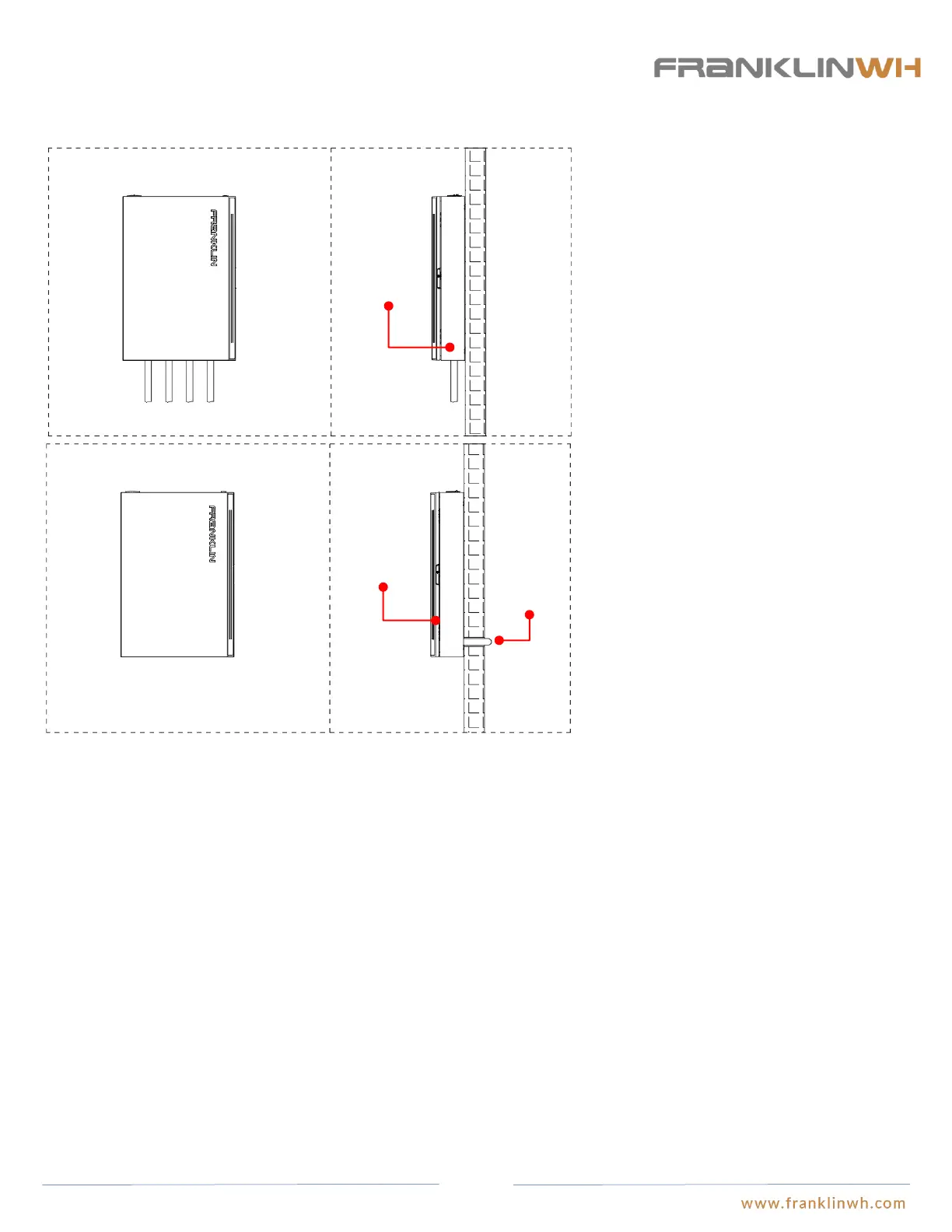

Scenario 1: Cables pass through the electric conduits and

enter aGate from the same side of the wall. Gasketed

junction boxes and conduit connections will be needed

to ensure the IP grade (water resistance) of aGate. The

electric conduit diameter varies by the types of conduits:

the knockout holes on the left and lower panel of aGate

are 35mm in diameter, while the knockout holes on the

upper panel are 63mm and 22mm in diameter. If the

knockout holes do not match the electric conduits in

size, additional reducing fittings will be needed to

achieve the required IP grade. If aGate is installed

outdoors, the electric conduits attach to aGate through

the cable inlet on the upper panel, and water-proof

sealant or caulk should be used at each connection of the

reducing fitting, junction box, electric conduit, and

aGate, in order to enhance the watertightness.

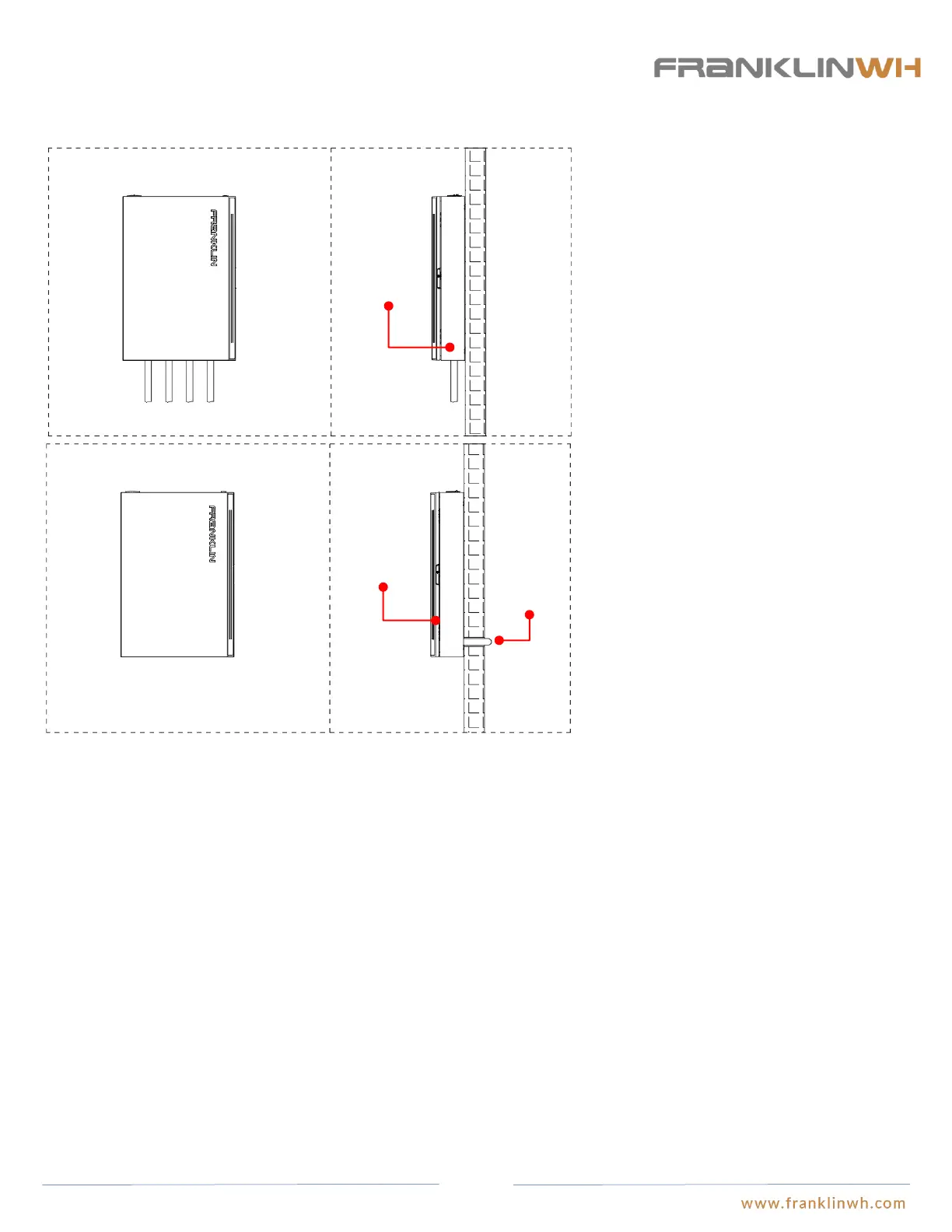

Scenario 2: Cables are run in electric conduits and enter

aGate from inside the wall or through the wall: in this

case, gaskets will be needed to ensure the IP grade

(water tightness) of aGate. The electric conduit diameter

varies by the types of conduits: the knockout holes on

the left and lower panel of aGate are 35mm in diameter,

while the knockout holes on the upper panel are 63mm

and 22mm in diameter. If the knockout holes do not

match the electric conduits in Hub diameter, additional

reducing fittings will be needed to achieve the required

IP grade. If aGate is installed outdoors, the electric

conduits connect to aGate through the cable inlet on the

upper panel. Water-proof sealant or caulk should be used

between the reducing fitting, junction box, electric

conduit, and aGate, in order to enhance the

watertightness.

Run cables

into aGate

from inside

the wall or

through the

wall

Install aGate on

the front exterior

side of wall

aGate and electric

conduits share the

same side of the

wall.

Planning protection for aGate’s input connections

● aGate serves as the entrance to the Franklin Home Power system. Installation of proper lightning protection systems are required

before the input end of aGate. Over current protection measures are required to be installed before the aGate inputs or inside the

aGate. A breaker of 100A to 200A may be installed at the grid input connection and the fuel generator input connection. Please refer

to Step 6 of this Guide for the recommended models of breakers inside aGate.

Planning the types, sizes and routes of cable and electric conduits

● Please refer to Step 8 of this Guide for recommended cable types and wire diameters electric connections and communication

connections between aGate and aGate and between aGate and the residence’s power distribution system.

● The current carrying capacity of cables needs to be reduced as wires travel longer distances through electric conduits. Please refer

to the applicable information if Appendix B to NFPA 70.

● The relationship between wire diameters, cable numbers, and inner diameters of conduits should be taken into general

consideration as cables run through the electrical conduits. Please refer to Appendix C to NFPA 70 for the list of maximum numbers

of cables of the same size in the electric conduits and pipelines.

● The type of electric conduits depend on the installation type: indoor or outdoor. IMC, EMT and other thin-wall metal conduits are

recommended in case of indoor installation. These two types of conduits are cost effective and provides excellent anti-

electromagnetic interference and are easy to shape and to joint. In outdoor installation, GRC and RMC thick-wall conduits are

recommended, because they can provide effective mechanical protection and good tightness at the conduit joints. Thick-wall conduits

have a reduced flexibility disadvantage which makes bending and jointing very difficult.

FCC Requirements

● See Appendix 1 for the applicable FCC Requirements. Installer informs user of the contents in Appendix 1.

18

Loading...

Loading...