2008T Troubleshooting Guide

P/N 490292 Rev. A

CO- 6.2.0 CALIBRATE / TROUBLESHOOT COND CELLS

a) Install the hydraulics but do not screw in the rear panels.

b) ENSURING plenty of known good acid and LIQUID Bicarb plug FIRMLY into each.

c) Place the machine into Service Mode → Calibrate Sensors →

Cond Cells → (if equipped with a bibag Connector) Dialysate

Cells. DO NOT select Bicarb Cell!

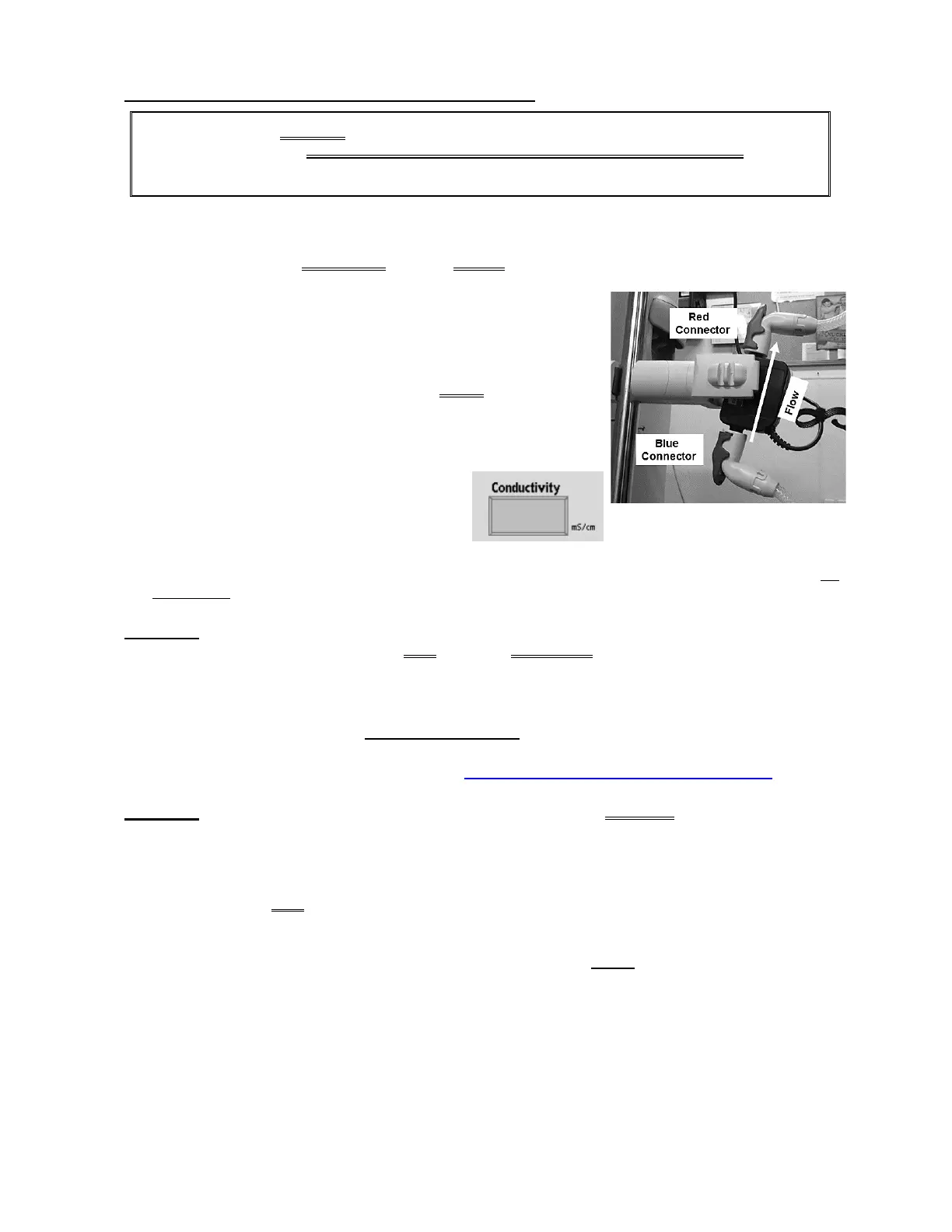

d) Install a Temperature / Conductivity meter into the dialysate

lines. Figure right, flow through the meter MUST directed from

bottom to top.

e)

Close the shunt door completely!

f) Follow the screen’s instructions through: “4.

Waiting until the Conductivity value is

stable.” The screen’s [Conductivity] data

box is initially gray.

g) ENSURING the external flow indicator’s ‘bob’ is moving at least ¼ way up the sight tube ALLOW six

(6) minutes before continuing to STEP #1 below:

STEP #1: Set the external meter to measure Temperature (°C). Watch it for thirty (30) seconds.

Between 35.1 and 39.9° C AND stable i.e. DOES NOT change more than +/- 0.25° C?

Yes Temperature between 35.1 and 39.9° C! Continue to STEP #2.

No a) Return to DIALYSIS PROGRAM (“Select Program” → ‘Dialysis’ → ‘Enter’)!

b) Proceed to page 232, SECTION 4 – TEMPERATURE PROBLEMS

STEP #2: Set the meter to measure Conductivity (mS). Its reading MUST BE between 13.0 and 14.5

mS?

Yes Between 13.0 and 14.5 mS! Continue to STEP #3 next page.

No NOT between 13.0 and 14.5 mS! See parts a AND b below.

a) SLAM the Loading Pressure gauge into the Acetate/Acid rinse port. If no masked

“No Water” or Flow Error alarms the gauge cycles, approximately EVERY three (3)

seconds, to about 25 psi. If not cycling return to Dialysis Program!

b) Proceed to

page 391, procedure number CO- 6.8.0.

NOTE! If an “Operator Error” banner appears but the flow indicator’s ‘bob’ continues to

move up and down ignore the banner. If the ‘bob’ NOT moving ‘Escape’ calibration

THEN return to procedure number CO- 6.2.0 (page 384).

While in Dialysis, ENSURE the machine is clear of “No Water”, Flow Errors and

Temperature alarms. Hydraulic alarm banners are not displayed in Service mode!

These are TROUBLESHOOTING procedure! Perform EXACTLY as written to avoid error!

Loading...

Loading...