2008T Troubleshooting Guide

P/N 490292 Rev. A

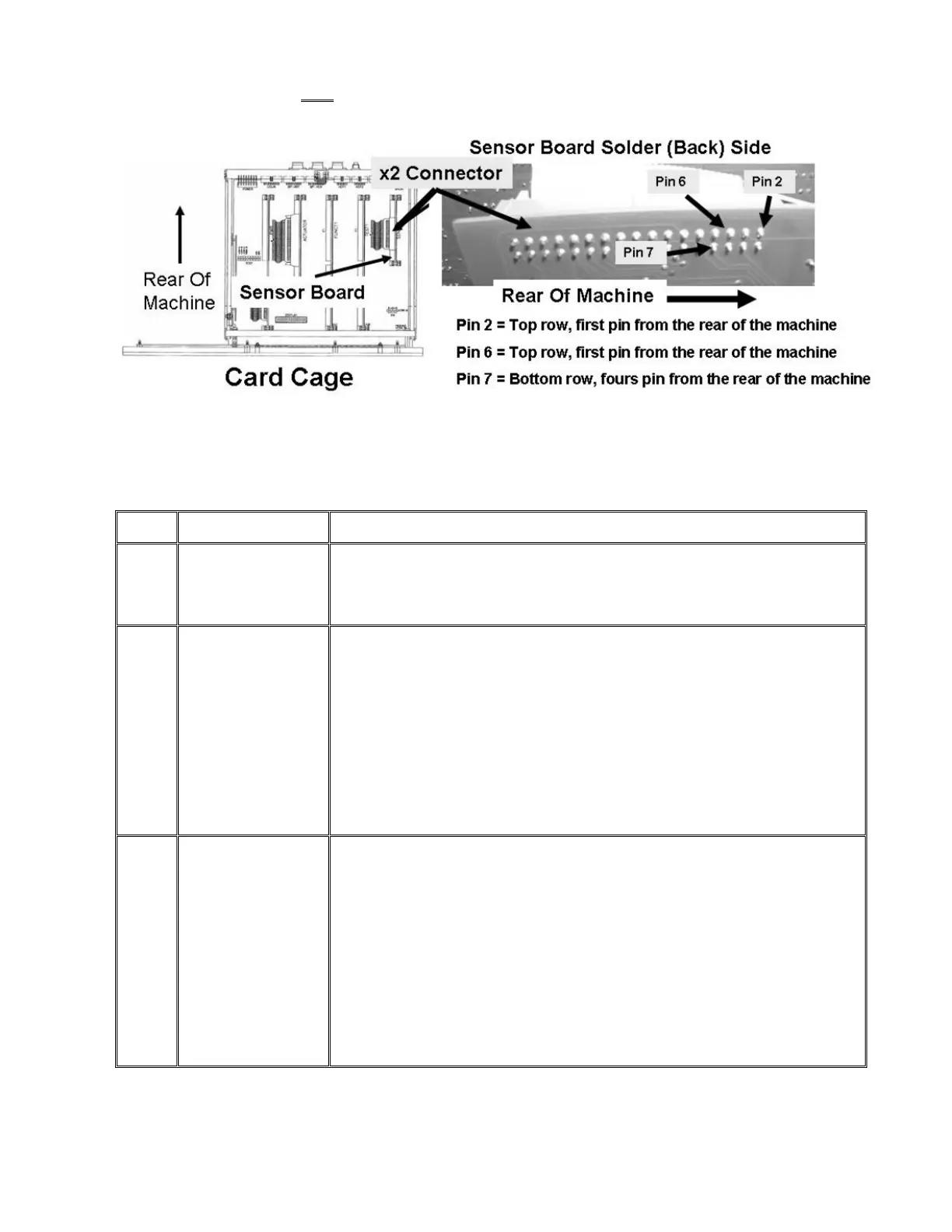

E) Per the Figure below AND as directed in Table 11 below, measure from the solder (back) side of the

Sensor Board’s X2 connector starting at pin #2:

Figure 90 – Electronic Card Cage (Sensor Board)

Table 11 – Sensor Board ‘X2’ DC Voltage Checks (Refer also to Figure 90)

X2 Pin

X2 Pin Location Your Response:

2 Top row, first pin

from the REAR of

the machine

• IF less than 0.5 volts DC: Measure at pin 6 (next row in table)

• IF more than 0.5 volts DC: Bad Actuator-Test Board (see page 10).

6 Top row, third pin

from the REAR of the

machine

• IF less than 4.5 volts DC: See procedure number BL- 6.0.0 (page 565).

• IF more than 5.2 volts DC: See procedure number BL- 6.0.0 (page 565).

• IF between 4.5 and 5.2 volts DC: From debug screen 4, does LEAK = the pin

6 measurement within +/- 0.3 volts DC?

Yes LEAK = pin 6 (+/- 0.3). Measure at pin 7 (next row in table).

No LEAK NOT within +/- 0.3 of pin 6 = Bad Sensor Board (see page 10).

7 Bottom row, fourth

pin from the REAR of

the machine

• IF less than 4.0 volts DC: See procedure number BL- 6.0.0 (page 565).

• IF more than 6.0 volts DC: See procedure number BL- 6.0.0 (page 565).

• IF between 4.0 and 6.0 volts DC: From debug screen 4, does DIMN = the pin

7 measurement within +/- 0.3 volts DC?

Yes DIMN = pin 7 (+/- 0.3). See procedure number BL- 6.0.0 (page 565).

No DIMN does NOT within +/- 0.3 of pin 7= Bad Sensor Board (see page 10).

Loading...

Loading...