2008T Troubleshooting Guide

P/N 490292 Rev. A

CO- 8.2.3 BIBAG EQUIPPED.

Call debug screen 14. WITHOUT LOOKING AWAY watch Air (4

th

column from left, 3

rd

window down) for one (1) minute. Does Air ever = 1?

3) IF (and ONLY if) Air = 0 ALWAYS (NEVER = 1): See procedure number CO- 8.2.4 (page 403).

4) IF Air = 1: See parts a THROUGH e below:

a) ENSURE no air through the clear Bicarbonate inlet tubing! This may cause Air = 1!

b) ENSURE screen 14’s Conductivity (2

nd

column from left, bottom row) is MORE THAN 48.00

indicating the bicarb AND Bicarb Pump is good. Bad bicarbonate will cause AIR = 1!

c) Remove the hydraulics from the cabinet!

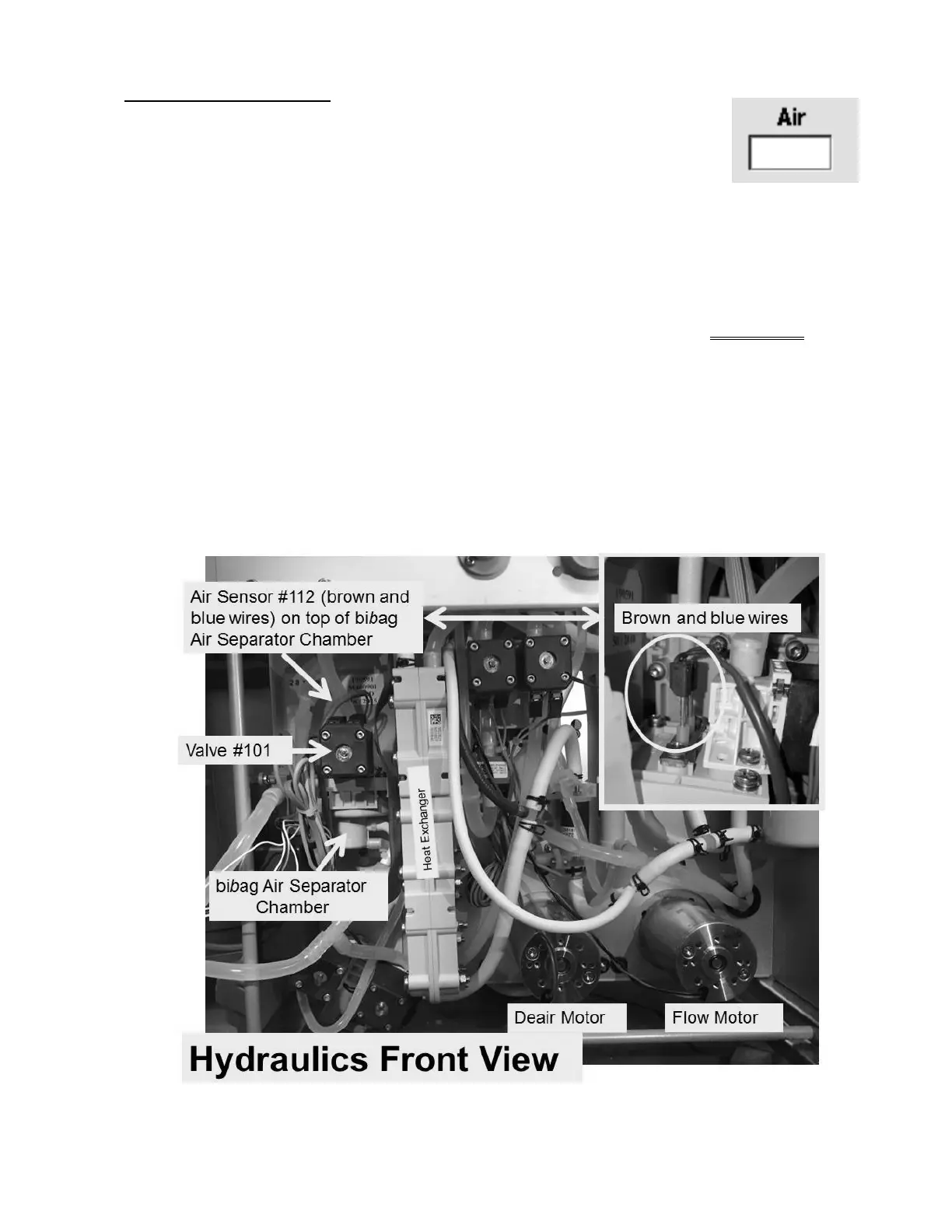

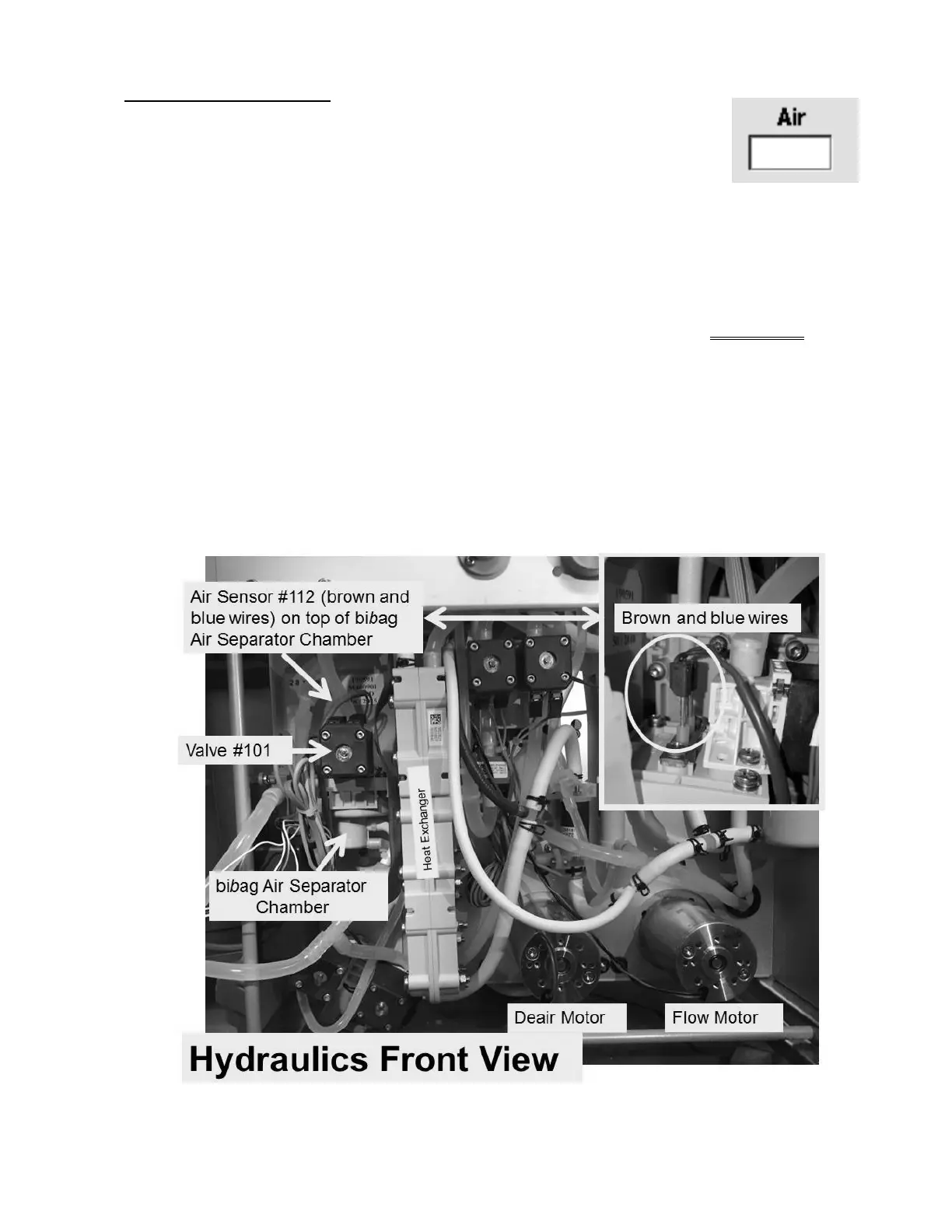

d) Figure below, ENSURE the blue and brown wires are attached securely to their probes on top of

the bibag Air Separator Chamber! If not this will cause AIR = 1!

e) If Air still = 1 FOUR (4) possible problems: 1) Loose bibag Interface Board ribbon cable (refer to

Figure 4C (page 11)) OR; 2) Bad bibag Interface Board OR; 3) Bad connection, from Air Sensor

#112, inside the bibag Distribution Board (refer to Figure 4D (page 13) OR; 4) Bad bibag Air

Separator Chamber.

Loading...

Loading...