RWB II ROTARY SCREW COMPRESSOR UNITS

OPERATION

S70-200 IOM

Page 18

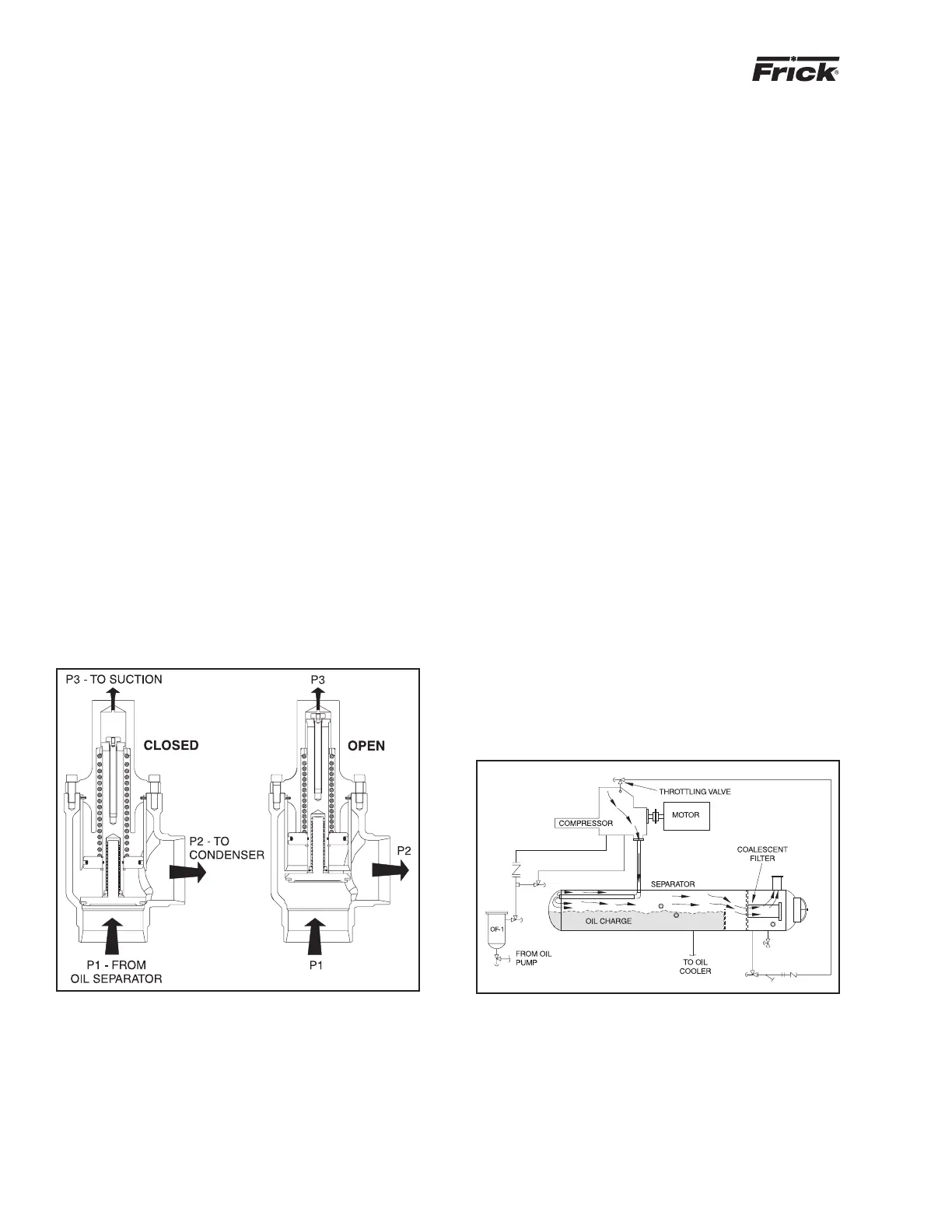

For high-stage packages, the cold-start valve is equipped

with a large spring that creates 30 psi of pressure in the oil

separator (above suction pressure), for lubrication of the

com pres sor.

DO NOT ATTEMPT TO SERVICE THE COLD START

VALVE. PLEASE CONTACT THE FRICK SERVICE

DE PART MENT.

Once the compressor is running it will begin to force gas to

the condenser at connection P2. As the condenser heats up

it will begin to rise in pressure as the compressor suc tion

pulls down in pressure. As soon as differential pres sure is

developed between the condenser and suction, these pres-

sures act across a piston inside the cold-start valve to par tial ly

overcome the spring force. When the differential pres sure

reaches and exceeds 30 psi, the piston fully over comes the

spring force and powers the valve fully open for very low

operating pressure drop.

For booster applications, the valve is equipped with a light er

spring which produces 15 psi oil pressure above suction

pres sure before it fully powers open.

The RWB II package is also equipped with a suction check

valve by pass. The oil separator will slowly bleed down to

sys tem suction pressure when the unit is stopped. This al lows

the compressor drive motor to have an easier start, and the

dis charge check valve will seat more tightly. See the "SUC-

TION CHECK VALVE BYPASS" section for op er a tion.

NOTE: For alarm descriptions and shutdown or cutout

pa ram e ters, see publication S90-010 O.

COLD START VALVE

DEMAND PUMP OIL SYSTEM

This system is designed to provide adequate compressor

lubrication for some high stage ap pli ca tions that operate with

low differential pres sure across the com pres sor suc tion and

dis charge and all booster applications.

During the period from start-up to normal operation the oil

pressure alarm and oil pressure cutout setpoints will vary

according to formulas built into the mi cro pro ces sor con trol

program.

NOTE: For alarm descriptions and shutdown or cutout

pa ram e ters, see publication S90-010 O.

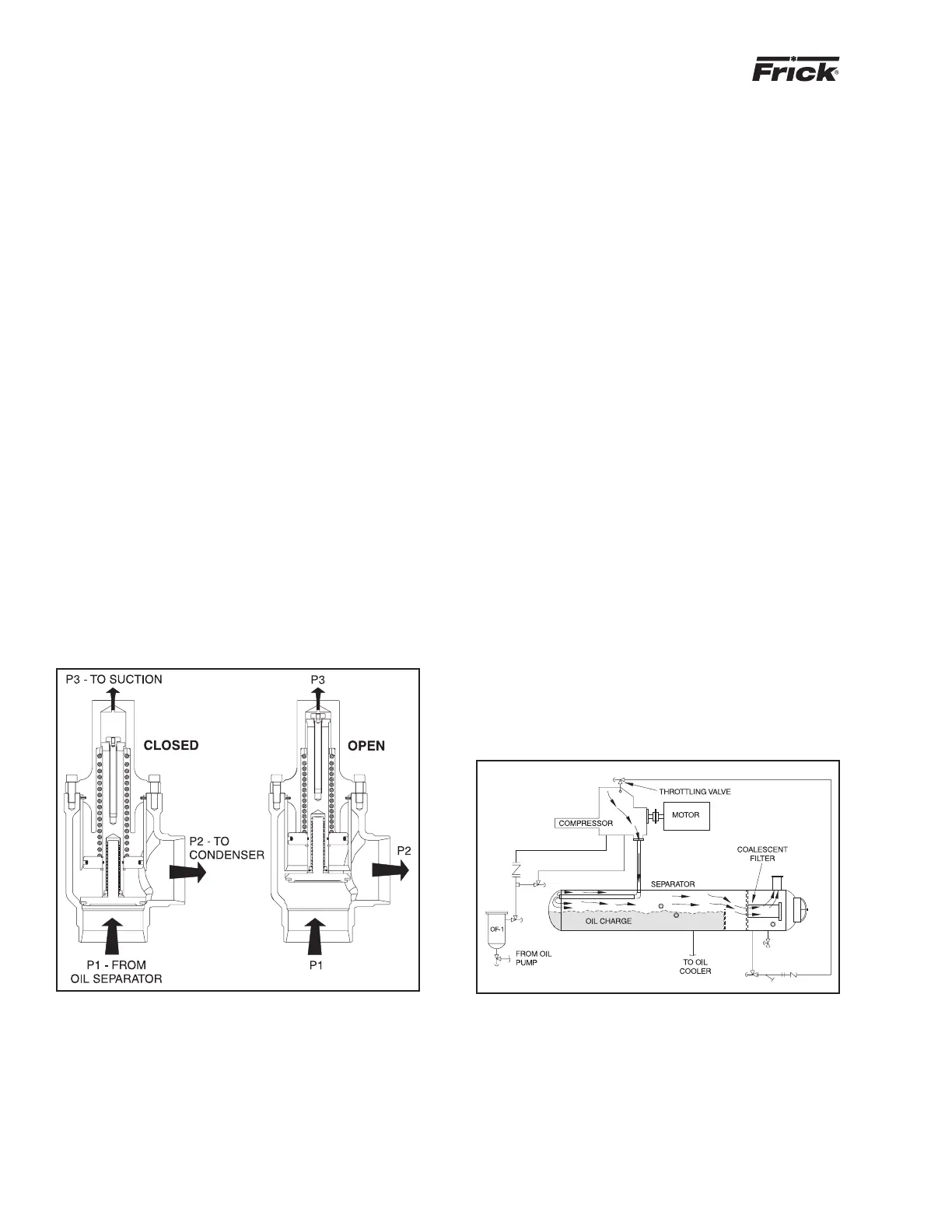

COMPRESSOR OIL SEPARATION SYSTEM

The RWB II is an oil fl ooded screw compressor. Most of the

oil discharged by the compressor separates from the gas fl ow

in the oil charge reservoir. Some oil, however, is dis charged

as a mist which does not separate readily from the gas fl ow

and is carried past the oil charge reser voir. One or more

coalescer fi lter elements then COALESCE the oil mist into

droplets which fall to the bottom of the co a lesc er sec tion of

the oil separator. The return of this oil to the com pres sor is

controlled by a throttling valve on both high stage and boost er

applications (see Figure 19).

NOTE: Open throttling valve only enough to keep co-

a lesc er end of separator free of oil.

The sight glass located near the bottom of the coales cer sec-

tion of the oil separator should remain empty during nor mal

operation. If an oil level develops and remains in the sight

glass, a problem in the oil return separation sys tem or com-

pres sor operation has developed. Refer to MAIN TE NANCE

for information on how to correct the prob lem.

NOTE: Normal op er at ing lev el is mid way be tween the

top sight glass and bot tom sight glass.

OIL SEPARATION SYSTEM

Figure 18

Figure 19

Loading...

Loading...