RWB II ROTARY SCREW COMPRESSOR UNITS

OPERATION

S70-200 IOM

Page 22

SUCTION CHECK VALVE

Low temperature booster compressor operations require

a more pos i tive suction check valve closure. This is ac-

com plished by al low ing the high stage discharge pres sure

gas to assist the spring tension and intermediate pres sure

clos ing force.

Frick provides a power assist kit consisting of a mounted

and wired so le noid valve and tim er on all RWB II booster

compressors. High stage compressors are supplied with

a power assist kit when the de sign suc tion tem per a ture is

less than or equal to 0°F. The wiring di a gram in S90-010 M

(Quan tum) or S70-200 OM (Plus) shows the wiring in clud ed

when re quired. In tro duc tion of high dis charge pres sure gas

is made to the check valve. A timer limits the high pressure

gas to only thirty sec onds du ra tion since in ter me di ate gas

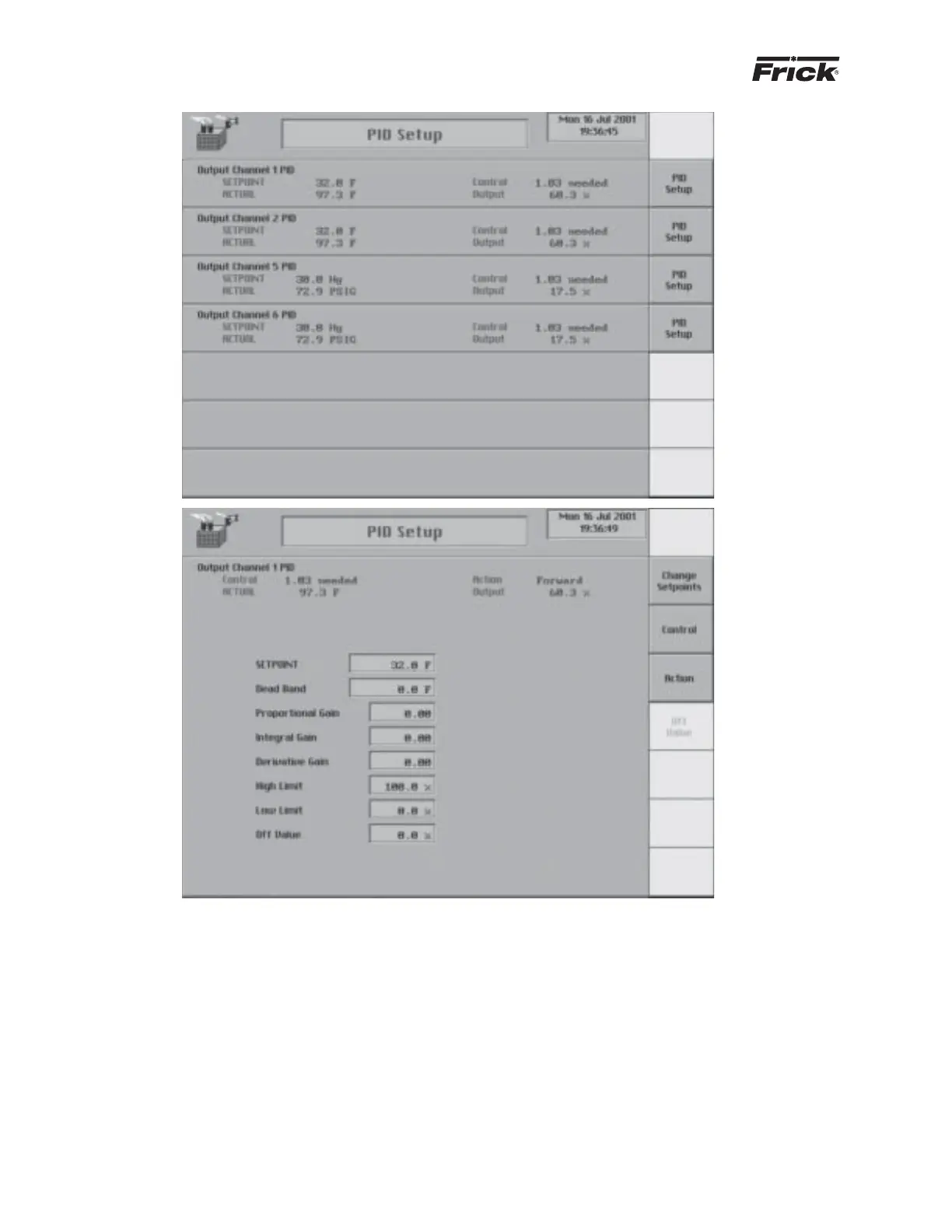

Figure 23

Figure 22

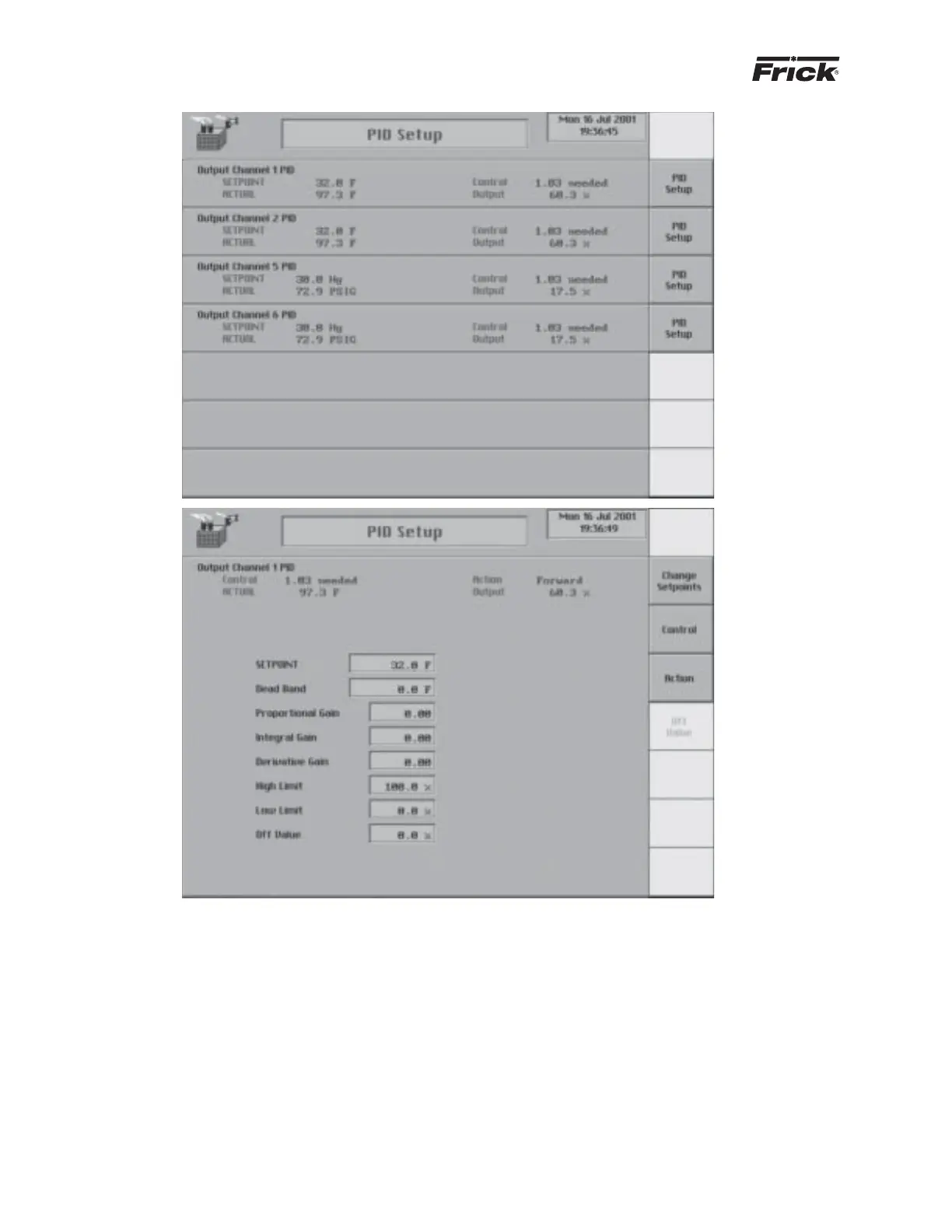

Use the [Control], [Action] and [Off Value] keys to set the

following:

• Set the Control for: When Running

• Set the Action for: Forward

• Set the Off Value for: 0%

• The ACTUAL value should be reading the current dis-

charge temperature.

• The Output should be reading 0% with the machine

off line.

• Regarding the adjustment of the Proportional Gain

setpoint, the goal is to increase or decrease the Pro-

portional Gain setpoint, until the discharge temperature

holds within or close to the Dead Band with minimal

fl uctuation of the output signal.

Loading...

Loading...