RWB II ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-200 IOM

Page 37

TEMPERATURE and/or PRESSURE

ADJUSTMENT

All temperature and pressure sensors are factory set. If cal i -

bra tion is required, refer to Analog Calibration for tem per a ture

or pressure in S90-010 O (Quantum panel) or Analog Off set

Display in S70-200 OM (Plus panel).

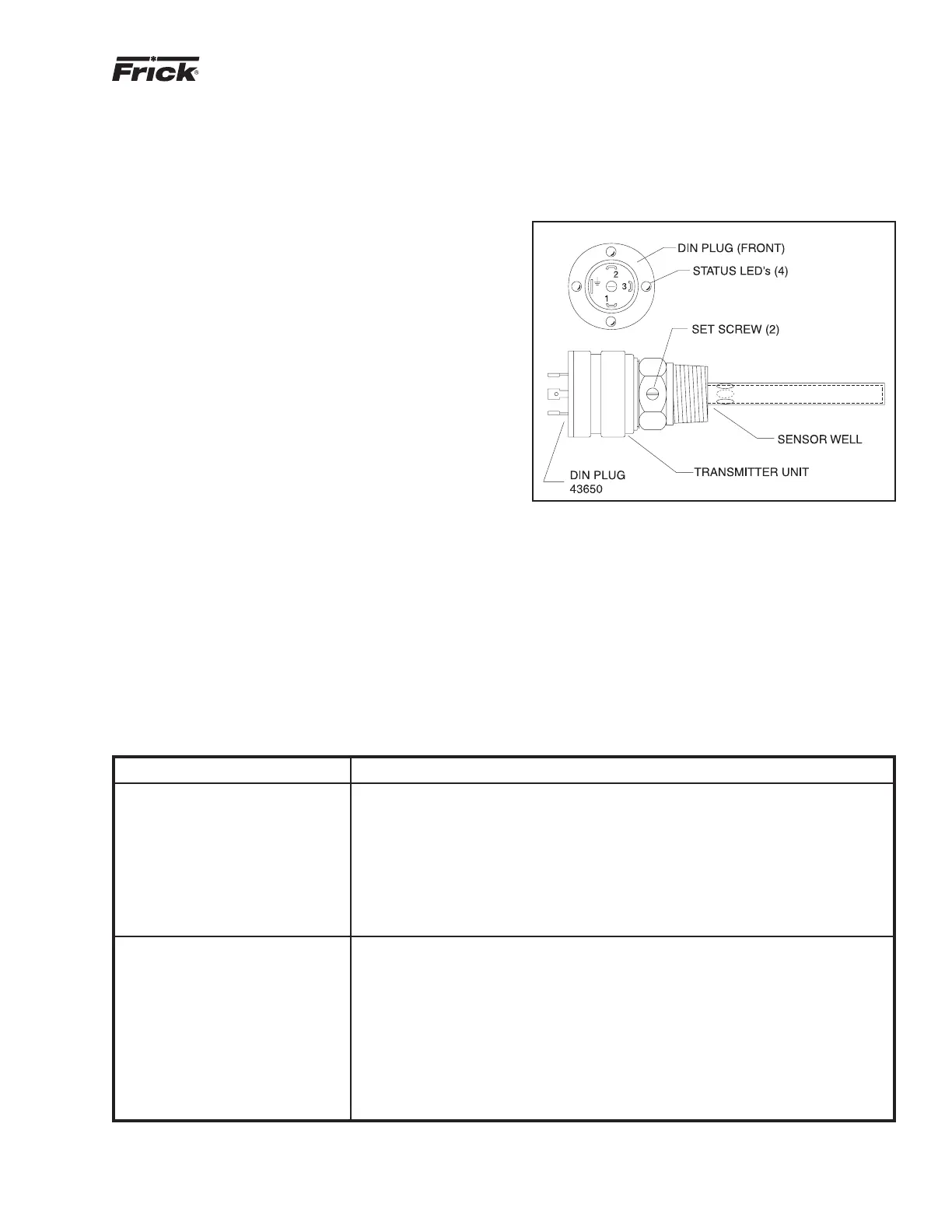

OIL LEVEL TRANSMITTER

REPLACEMENT

The Oil Level Transmitter is located on the front of the sep a -

ra tor near the bottom/center. See Figure 34.

The linear transmitter with hermetic enclosure is based on

the capacitive measuring principle. It features removable

elec tron ics (from the sensor well) eliminating the need to

evac u ate the compressor for replacement. This transmitter is

ded i cat ed to oil level control and has no user ad just ments.

1. Shut off control power.

2. Remove DIN connector plug from transmitter.

3. Loosen set screws.

4. Remove transmitter unit.

5. Install new transmitter unit.

6. Tighten set screws.

7. Apply DIN connector plug to transmitter.

8. Turn on control power.

Figure 34

TROUBLESHOOTING THE RWB II COMPRESSOR

SYMPTOM PROBABLE CAUSES and CORRECTIONS

EXCESSIVE NOISE and VIBRATION Main oil injection valve may be closed. Open valve.

Bearing damage or excessive wear. CONTACT Frick Factor or Frick.

Coupling loose on shaft. Tighten coupling. Replace if damaged.

Misalignment between motor and compressor. Realign motor and compressor.

Refrigerant fl ood back. Correct system problem.

SLIDE VALVE and/or SLIDE STOP 4-way hydraulic control valve failed - repair or replace.

WILL NOT MOVE

Slide stop indicator rod stuck. Contact Frick Factor or Frick for assistance.

Check both S.V. and S.S. potentiometer for wiring and resistance.

Compressor must be running with suffi cient oil pressure.

Unloader piston stuck. Contact Frick Factor or Frick for assistance.

Slipper seals worn out or damaged. Contact Frick Factor or Frick for assistance.

NOTE: Troubleshooting the compressor is limited to identifying the probable cause. If a mechanical problem is suspected, contact the

Frick Service Department. DO NOT ATTEMPT TO DISASSEMBLE COMPRESSOR.

Loading...

Loading...