RWB II ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-200 IOM

Page 23

pres sure and spring ten sion are suf fi cient to main tain clo sure

on unit shut down. A me ter ing valve is also pro vid ed for use as

a service valve and to allow dis charge gas fl ow reg u la tion to

prevent ex ces sive force and resulting clo sure “ham mer ing”.

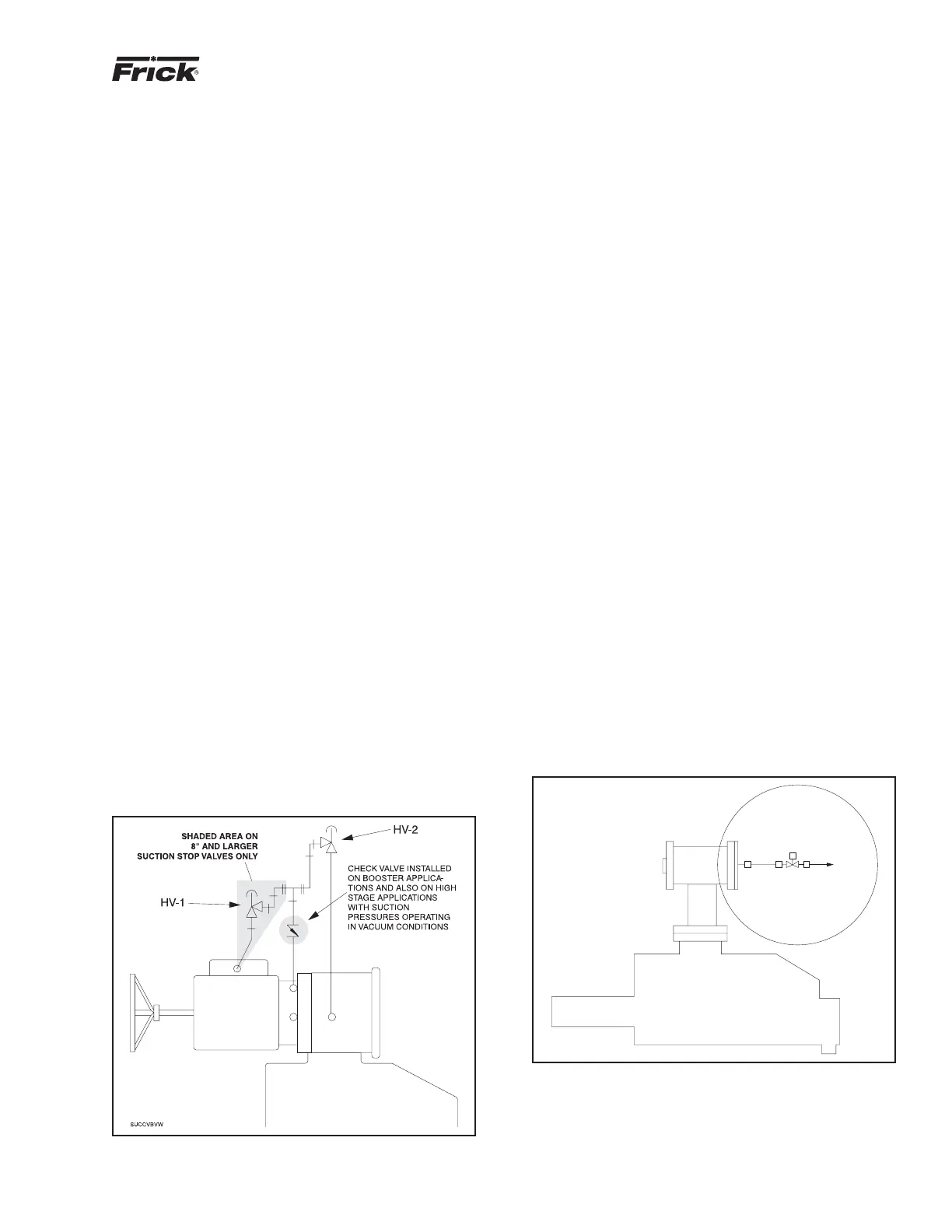

SUCTION CHECK VALVE BYPASS

During normal operation, valve HV1 is closed. This is a pump-

out connection to allow refrigerant removal to the system

suction prior to evacuation for servicing. Valve HV-2 must

be open in most systems at all times. It should normally be

cracked open to allow the oil separator to slowly bleed down

to system suction pressure when the unit is stopped (hav ing

this valve cracked open allows the compressor drive mo tor to

have an easier start, and the discharge check valve will seat

more tightly). If the drive coupling backspins, start closing the

valve until the backspin stops. If the sep a ra tor oil lev el foams

ex ces sive ly on shutdown, HV-2 should be closed slight ly. If

the separator takes more than 20 – 30 minutes to equalize

to suction pressure after shut down, HV-2 can be opened

slightly. See Figure 24.

NOTE: HV-2 should be closed on systems with suc tion

pres sures below atmospheric pressure, to avoid the pos-

si bil i ty of air leakage into the system during shut down.

However, on high-stage or boost er sys tems with check

valve, HV-2 can remain open.

HV-2 also should be closed on systems that utilize au to cy cle

to restart the compressor, based on increase in sys tem

suc tion pressure during shutdown, if slowly bleed ing the

oil sep a ra tor gas to suction will raise the suction pres sure

enough to cause short cycling of the compressor.

Also it is important to close HV-2, if the oil pump is to be run

for long periods of time with the compressor stopped, to avoid

oil being pumped up the suction line.

If multiple compressors are operated with a common econ-

o miz er vessel, it is necessary to install a back-pressure

reg u la tor valve with an electric shut-off option in the vapor

line piped to the compressor's economizer port. If an electric

shut-off is not installed in the economizer vapor line, valve

HV-2 must remain closed to avoid a gas bypass from the

econ o miz er line through the suction check valve bypass, back

to the suction line on a compressor that is shut down.

Figure 24

LOW AMBIENT OPERATION

It is recommended that oil separators be insulated as a min-

i mum requirement to preserve the heat generated by the oil

heaters. It is important that the coalescer end of the sep a ra tor

be insulated to prevent refrigerant con den sa tion.

On systems located outdoors or in unheated buildings where

the ambient temperature could drop below +40°F, in su lat ing

and/or heat tracing of the compressor lube oil systems is

highly recommended.

When low ambient temperatures (below +20°F) are a pos-

si bil i ty, it is recommended that lube oil lines, oil fi lters, oil

pumps and oil cool ers be heat traced and insulated.

Freeze-up protection must also be provided for all water-

cooled equipment

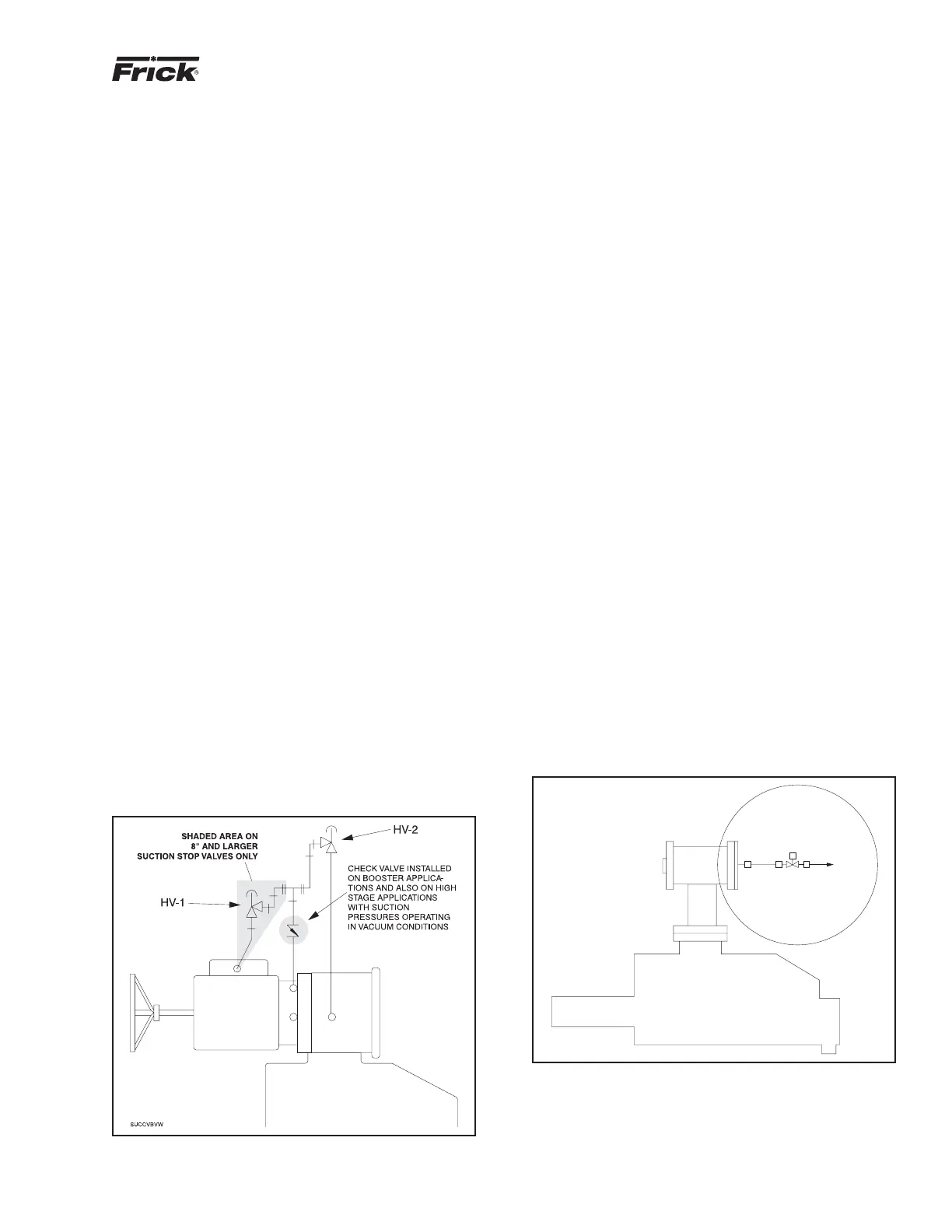

SUCTION CHECK VALVE

POWER ASSIST KIT

Low temperature booster compressor operations re quire a

more pos i tive suction check valve closure. This is ac com -

plished by al low ing the high pressure discharge gas to as sist

the spring tension and intermediate pres sure clos ing force.

The power assist kit (Figure 25) is factory in stalled with the

dis charge gas pressure being supplied from a con nec tion

on the dry end of the oil separator. It may be nec es sary to

pro vide high pressure gas from a high stage com pres sor

dis charge for booster applications in which the operating

pres sure differential on the booster compressor is in suf fi cient

to close the suction check valve.

Frick provides a power assist kit consisting of a mounted

and wired so le noid valve and tim er on all RDB booster

com pres sors. Introduction of high dis charge pres sure gas

is made to the check valve. A timer limits the high pressure

gas to only thirty sec onds du ra tion since in ter me di ate gas

pres sure and spring ten sion are suf fi cient to main tain clo sure

on unit shut down. A me ter ing valve is also pro vid ed for use as

a service valve and to allow dis charge gas fl ow reg u la tion to

prevent ex ces sive force and resulting clo sure “ham mer ing”.

POWER ASSIST KIT

TO COMPRESSOR

DISCHARGE

PWRASST

S

Figure 25

Loading...

Loading...