36 PB

OPERATION

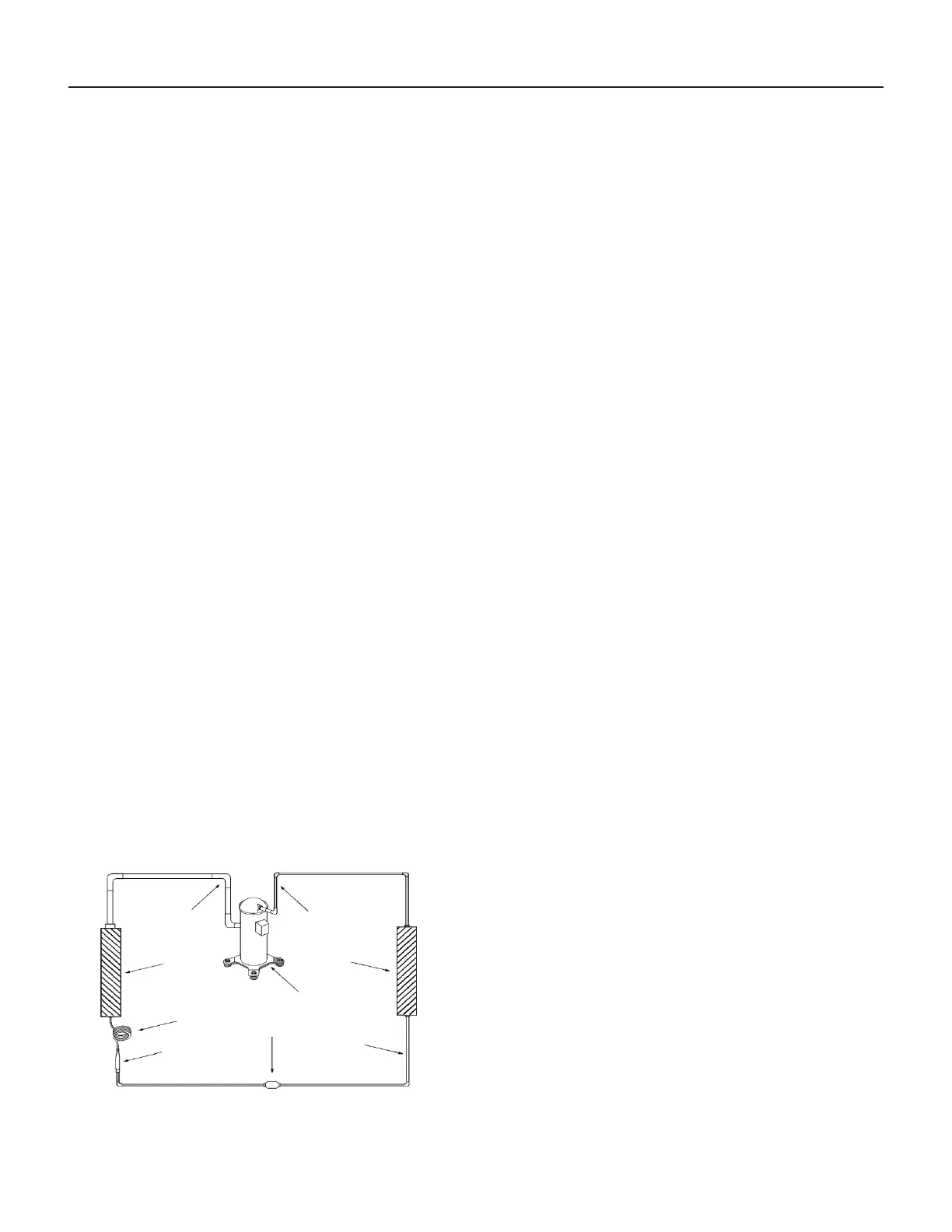

Refrigeration Sequence Of Operation

Agoodunderstandingofthebasicoperationoftherefrigerationsystemisessentialfortheservicetechnician.Withoutthis

understanding,accuratetroubleshootingofrefrigerationsystemproblemswillbemoredifcultandtimeconsuming,ifnot(in

somecases)entirelyimpossible.Therefrigerationsystemusesfourbasicprinciples(laws)initsoperationtheyareasfollows:

1. “Heatalwaysowsfromawarmerbodytoacoolerbody.”

2. “Heatmustbeaddedtoorremovedfromasubstancebeforeachangeinstatecanoccur”

3. “Flowisalwaysfromahigherpressureareatoalowerpressurearea.”

4. “Thetemperatureatwhichaliquidorgaschangesstateisdependentuponthepressure.”

Therefrigerationcyclebeginsatthecompressor.Startingthecompressorcreatesalowpressureinthesuctionlinewhich

drawsrefrigerantgas(vapor)intothecompressor.Thecompressorthen“compresses”thisrefrigerantvapor,raisingits

pressureandits(heatintensity)temperature.

TherefrigerantleavesthecompressorthroughthedischargeLineasahotHighpressuregas(vapor).Therefrigerantenters

thecondensercoilwhereitgivesupsomeofitsheat.Thecondenserfanmovingairacrossthecoil’snnedsurfacefacilitates

thetransferofheatfromtherefrigeranttotherelativelycooleroutdoorair.

Whenasufcientquantityofheathasbeenremovedfromtherefrigerantgas(vapor),therefrigerantwill“condense”(i.e.

changetoaliquid).Oncetherefrigeranthasbeencondensed(changed)toaliquiditiscooledevenfurtherbytheairthat

continuestoowacrossthecondensercoil.

Thedesigndeterminesatexactlywhatpoint(inthecondenser)thechangeofstate(i.e.gastoaliquid)takesplace.Inallcases,

however,therefrigerantmustbetotallycondensed(changed)toaLiquidbeforeleavingthecondensercoil.

TherefrigerantleavesthecondenserCoilthroughtheliquidlineasawarmhighpressureliquid.Itnextwillpassthroughthe

refrigerantdrier(ifequipped).Itisthefunctionofthedriertotrapanymoisturepresentinthesystem,contaminants,andlarge

particulatematter.

Theliquidrefrigerantnextentersthemeteringdevice.Themeteringdeviceisacapillarytube.Thepurposeofthemetering

deviceisto“meter”(i.e.controlormeasure)thequantityofrefrigerantenteringtheevaporatorcoil.

Inthecaseofthecapillarytubethisisaccomplished(bydesign)throughsize(andlength)ofdevice,andthepressuredifference

presentacrossthedevice.

Sincetheevaporatorcoilisunderalowerpressure(duetothesuctioncreatedbythecompressor)thantheliquidline,the

liquidrefrigerantleavesthemeteringdeviceenteringtheevaporatorcoil.Asitenterstheevaporatorcoil,thelargerareaand

lowerpressureallowstherefrigeranttoexpandandloweritstemperature(heatintensity).Thisexpansionisoftenreferred

toas“boilingoratomizing”.Sincetheunit’sblowerismovingindoorairacrossthennedsurfaceoftheevaporatorcoil,the

expandingrefrigerantabsorbssomeofthatheat.Thisresultsinaloweringoftheindoorairtemperature,or“cooling”.

Theexpansionandabsorbingofheatcausetheliquidrefrigeranttoevaporate(i.e.changetoagas).Oncetherefrigeranthas

beenevaporated(changedtoagas),itisheatedevenfurtherbytheairthatcontinuestoowacrosstheevaporatorcoil.

Theparticularsystemdesigndeterminesatexactlywhatpoint(inthe

evaporator)thechangeofstate(i.e.liquidtoagas)takesplace.Inall

cases,however,therefrigerantmustbetotallyevaporated(changed)

toagasbeforeleavingtheevaporatorcoil.

Thelowpressure(suction)createdbythecompressorcausesthe

refrigeranttoleavetheevaporatorthroughthesuctionlineasacool

lowpressurevapor.Therefrigerantthenreturnstothecompressor,

wherethecycleisrepeated.

Suction

Line

Evaporator

Coil

Metering

Device

Refrigerant

Strainer

Discharge

Line

Condenser

Coil

Compressor

Refrigerant Drier

Liquid

Line

Figure 345 (Refrigeration Sequence Of Operation)

Loading...

Loading...