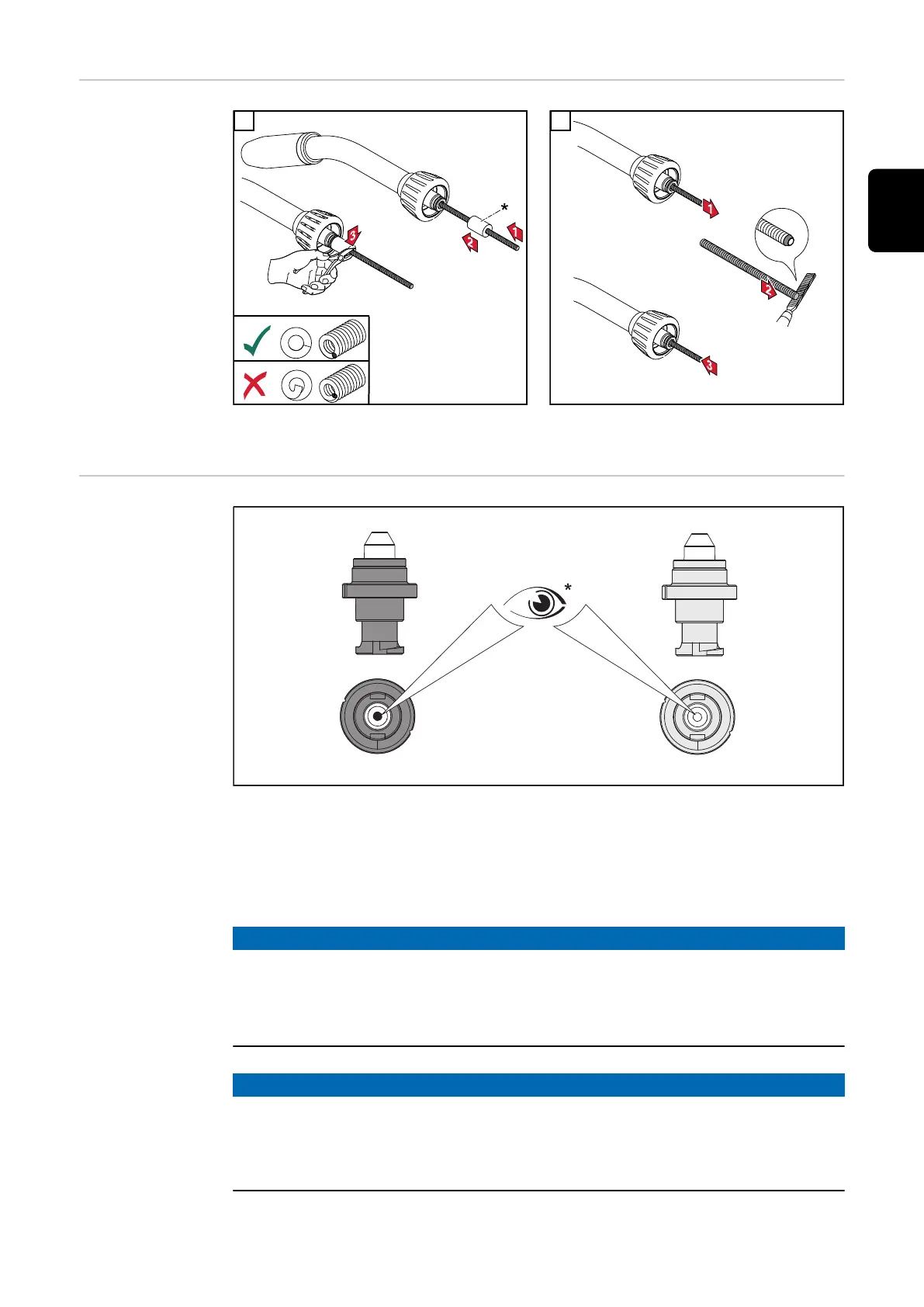

Inserting a steel

or CrNi inner li-

ner into the

torch body

1 2

* Use the welding torch cutting pipe (gas = 40 mm, water = 50 mm)

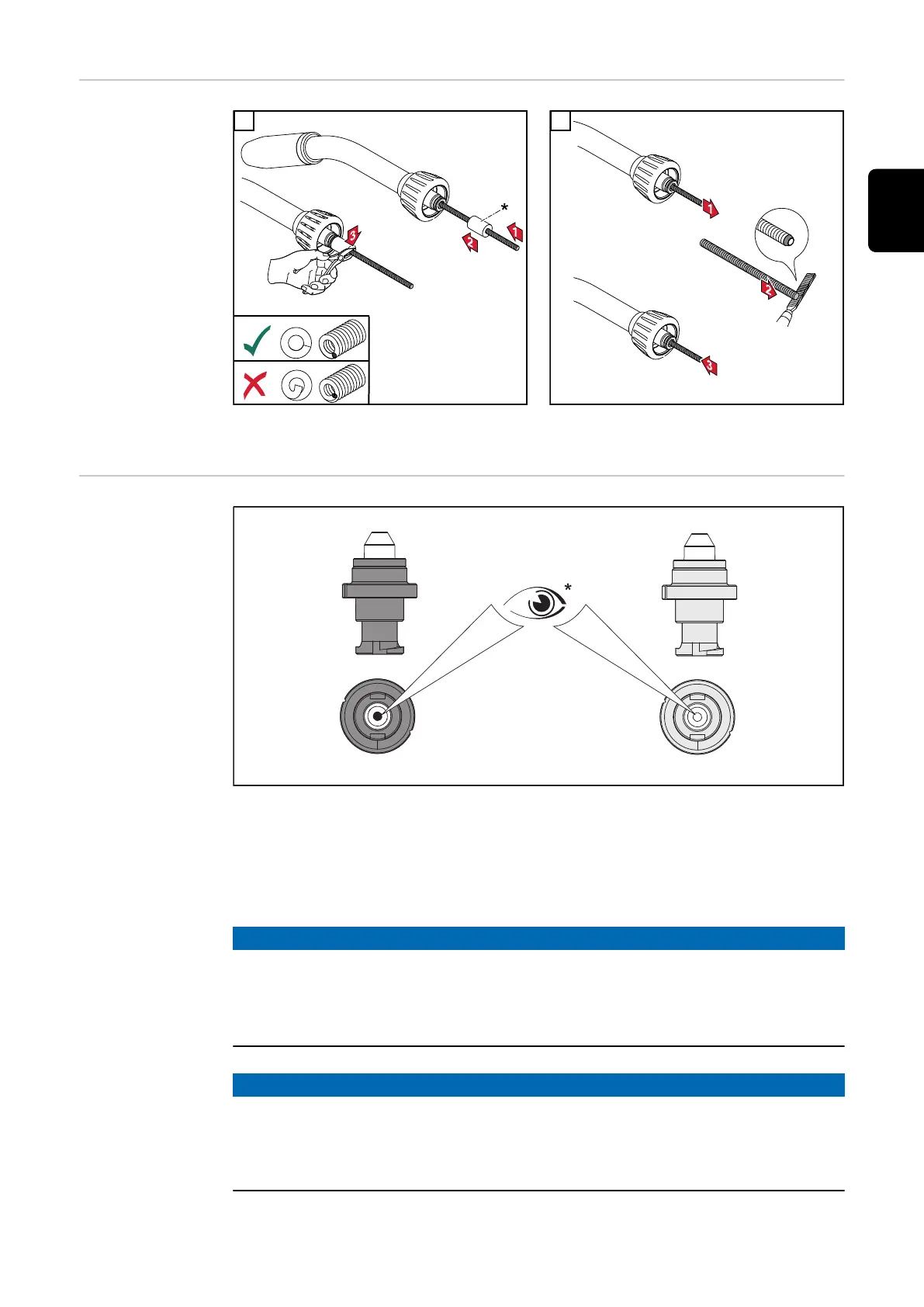

Checking the

clamping nipple

Push

Push-Pull

with sealing

without sealing

* Check the clamping nipple before commissioning and whenever the inner liner

is changed. To do so, carry out a visual inspection:

-

Left: brass clamping nipple with seal ring. You cannot see through the seal

ring.

-

Right: silver clamping nipple with see-through bushing

NOTE!

Incorrect or defective clamping nipple in push applications

Causes gas loss and poor weld properties

▶

use brass clamping nipples to minimise gas loss

▶

check that the seal ring is intact

NOTE!

Incorrect clamping nipple in push-pull applications

Tangled wire and increased abrasion in the inner liner when using a clamping

nipple with seal ring

▶

use silver clamping nipple to facilitate wirefeeding

47

EN

Loading...

Loading...