Care, maintenance and disposal

General Regular preventive maintenance of the welding torch is essential if trouble-free

operation is to be ensured. The welding torch is subjected to high temperatures

and heavy soiling. The welding torch therefore requires more frequent mainten-

ance than other components in the welding system.

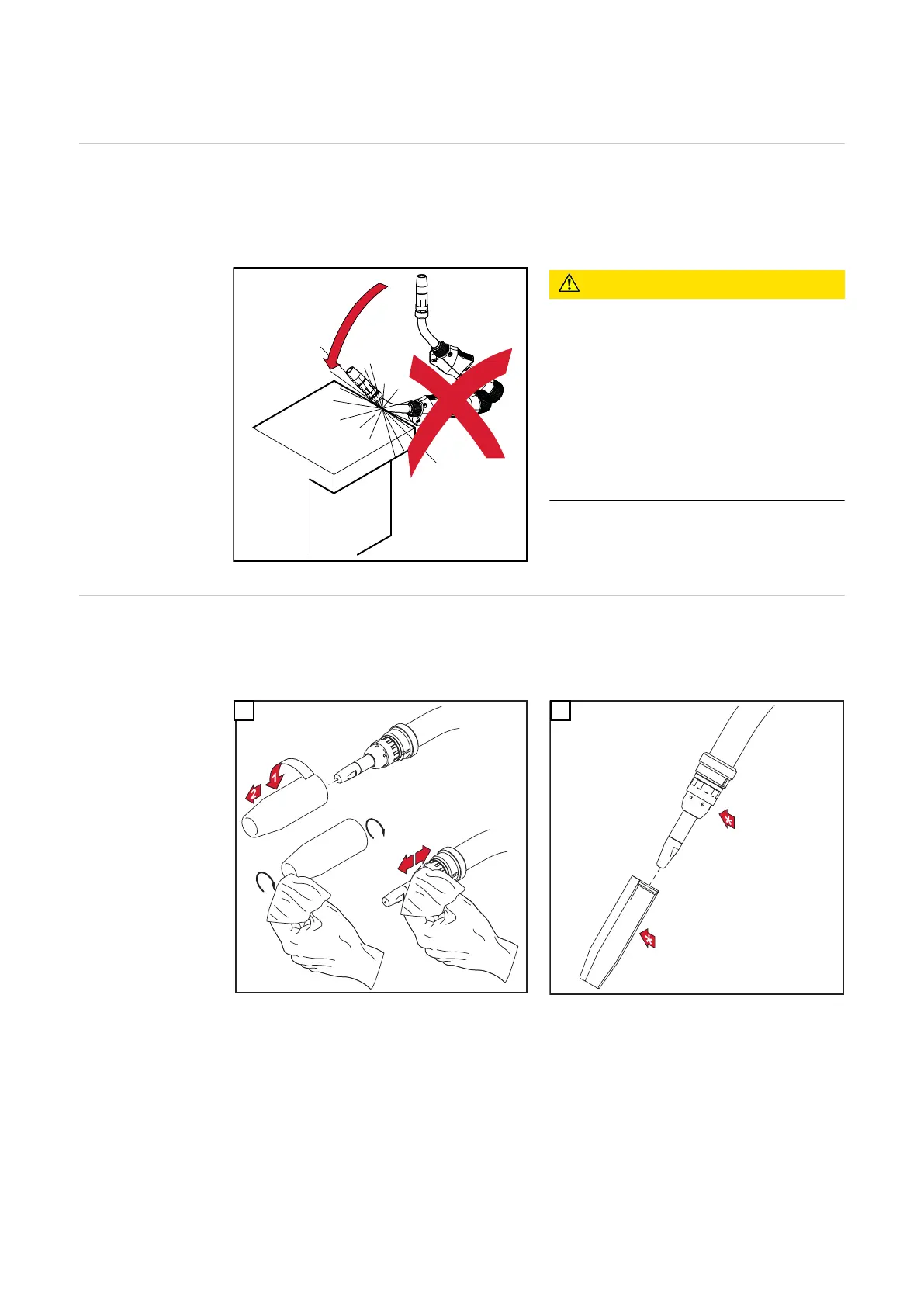

CAUTION!

Risk of damage from improper hand-

ling of the welding torch.

This can result in severe damage to

property.

▶

Do not strike the welding torch on

hard objects.

▶

Avoid scoring and scratches on the

contact tip.

▶

Do not bend the torch body under

any circumstances.

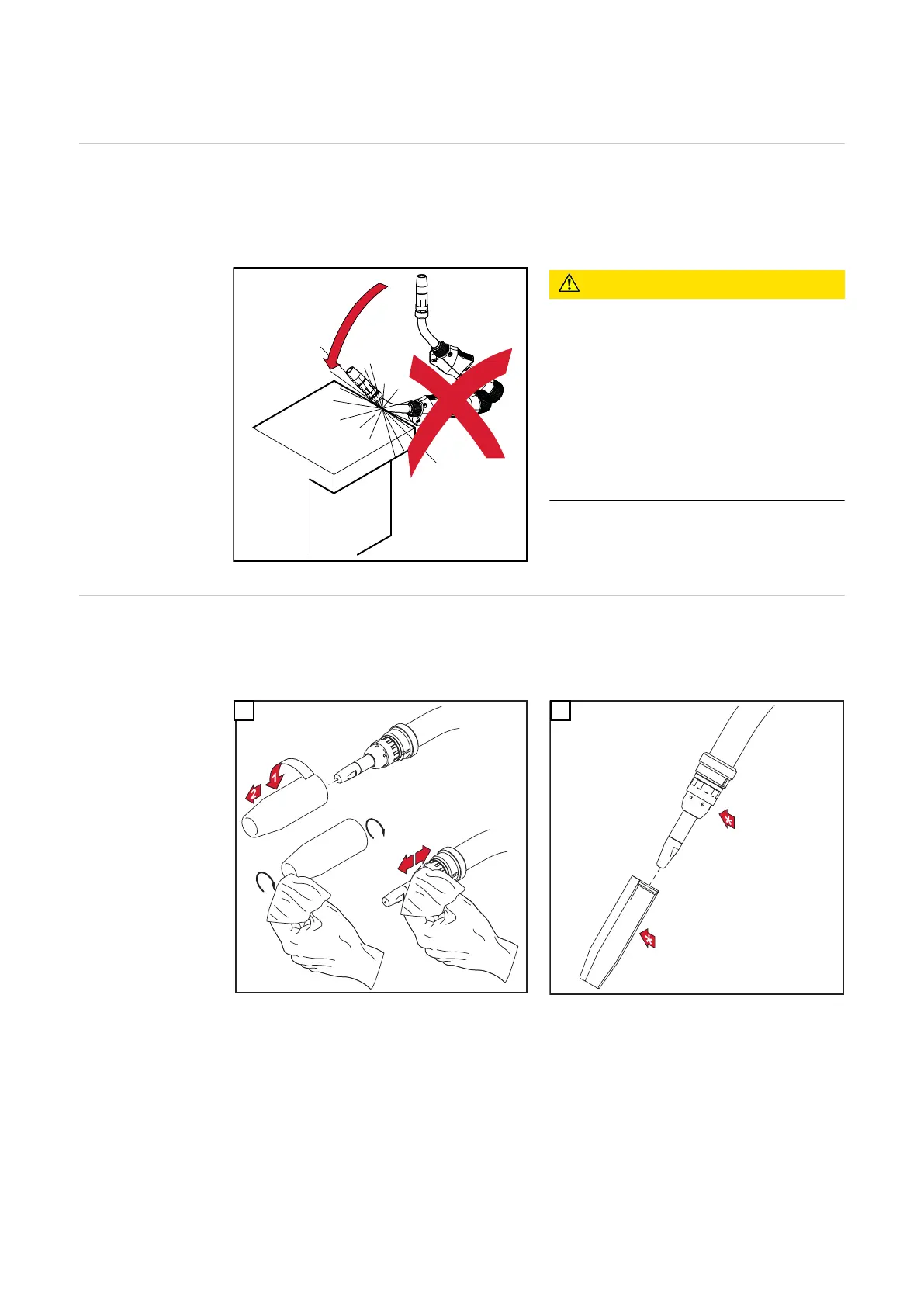

Maintenance at

every start-up

-

Check wearing parts

-

replace faulty wearing parts

-

Remove welding spatter from gas nozzle

1 2

* Check the gas nozzle, spatter guard and insulation for damage and re-

place any damaged components.

-

Also at every start-up when using water-cooled welding torches:

-

check all coolant connections for tightness (no leaks)

-

check that the coolant can flow unhindered

62

Loading...

Loading...