60

Starting current

> 100% (HotStart)

Advantages

- Improved ignition properties, even when using electrodes with poor ignition properties

- Better fusion of parent material in the start phase, therefore less neutralization

- Slag inclusions largely avoided

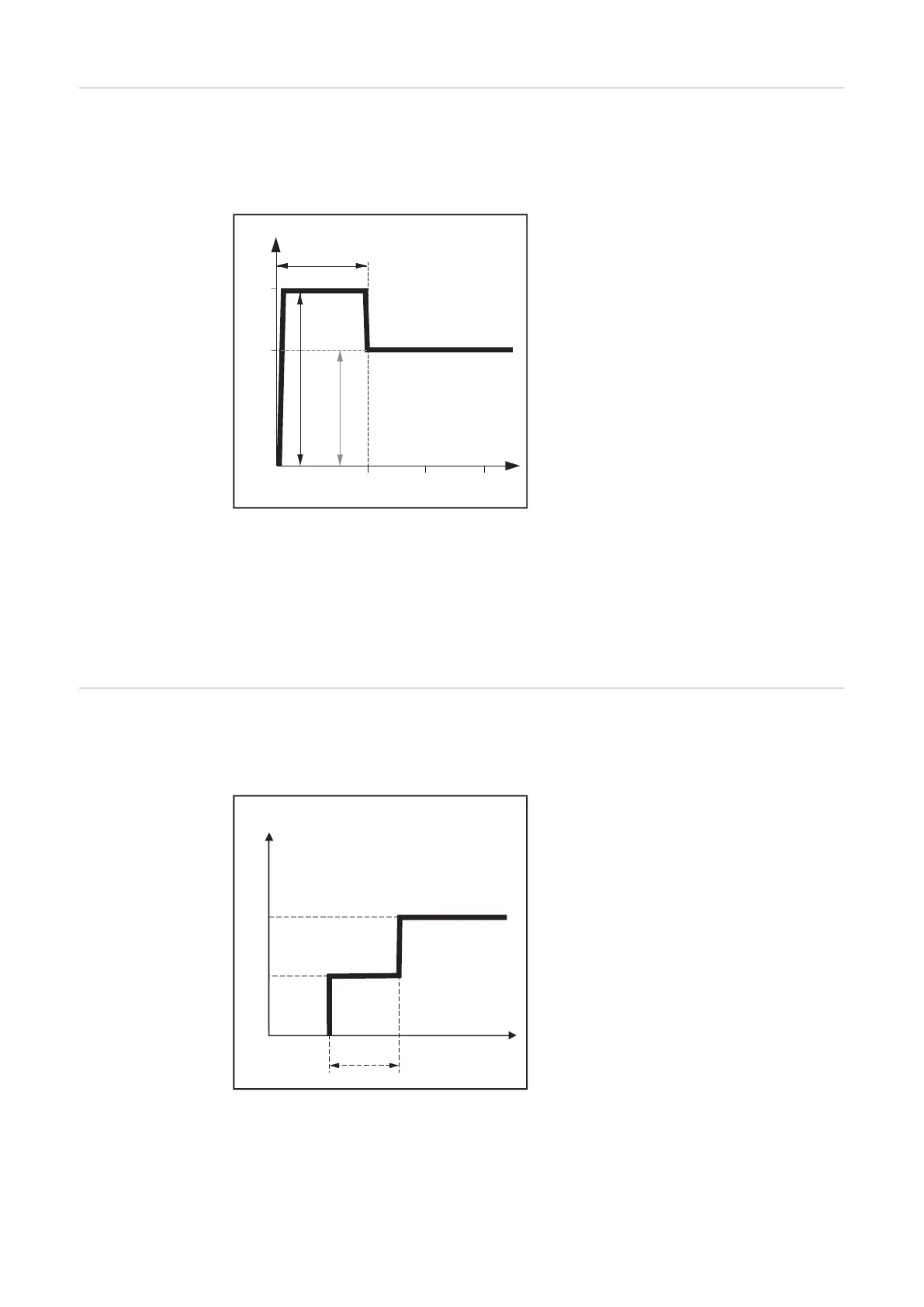

Example of a starting current > 100% (HotStart)

Key:

Hti

Hot current time,

0-2 s,

Factory setting 0.5 s

HCU

HotStart current,

0-200%,

Factory setting 150%

I

1

Main current = set welding current

Operation

During the set hot current time (Hti) the welding current I

1

rises to the HotStart current

HCU.

The setting of the available parameters is described in the "Setup Menu" section on page

76.

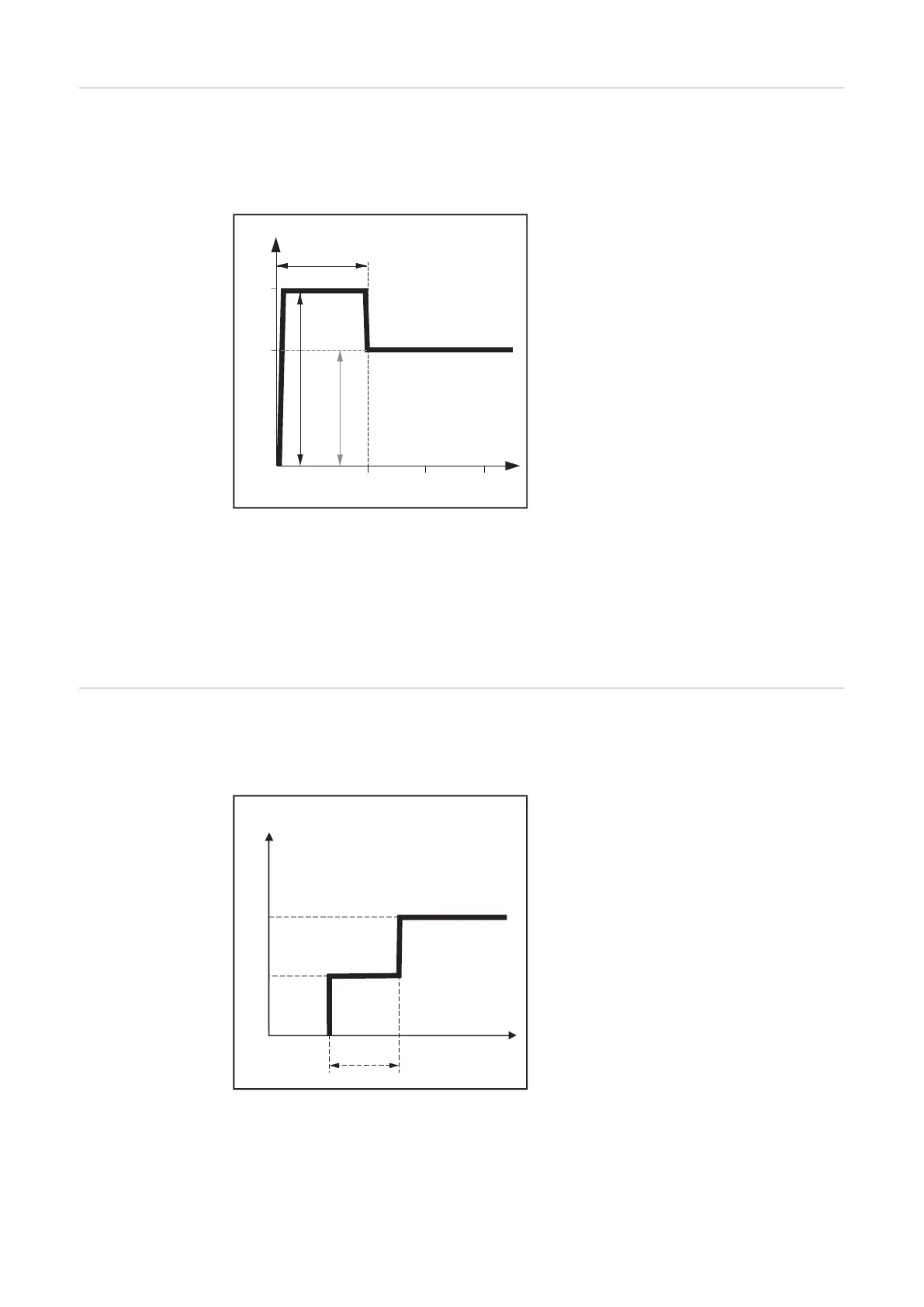

Starting current

< 100%

(SoftStart)

A starting current of < 100% (SoftStart) is suitable for basic electrodes. Ignition is carried

out with a low welding current. As soon as the arc is stable, the welding current continues

to increase until it reaches the welding current command value that was set.

Example of a starting current < 100% (SoftStart)

Advantages:

- Improvement of ignition properties with

electrodes that ignite at a low welding

current

- Slag inclusions largely avoided

- Reduction of welding spatter

(1) HCU starting current

(2) Hti starting current time

(3) Main current I

1

The starting current and starting current

time are set in the Setup menu from page

76.

I (A)

t (s)

0,5 1 1,5

Hti

I

1

HCU

100

150

I (A)

t (s)

90A

30A

(1)

(3)

(2)

Loading...

Loading...