73

EN-US

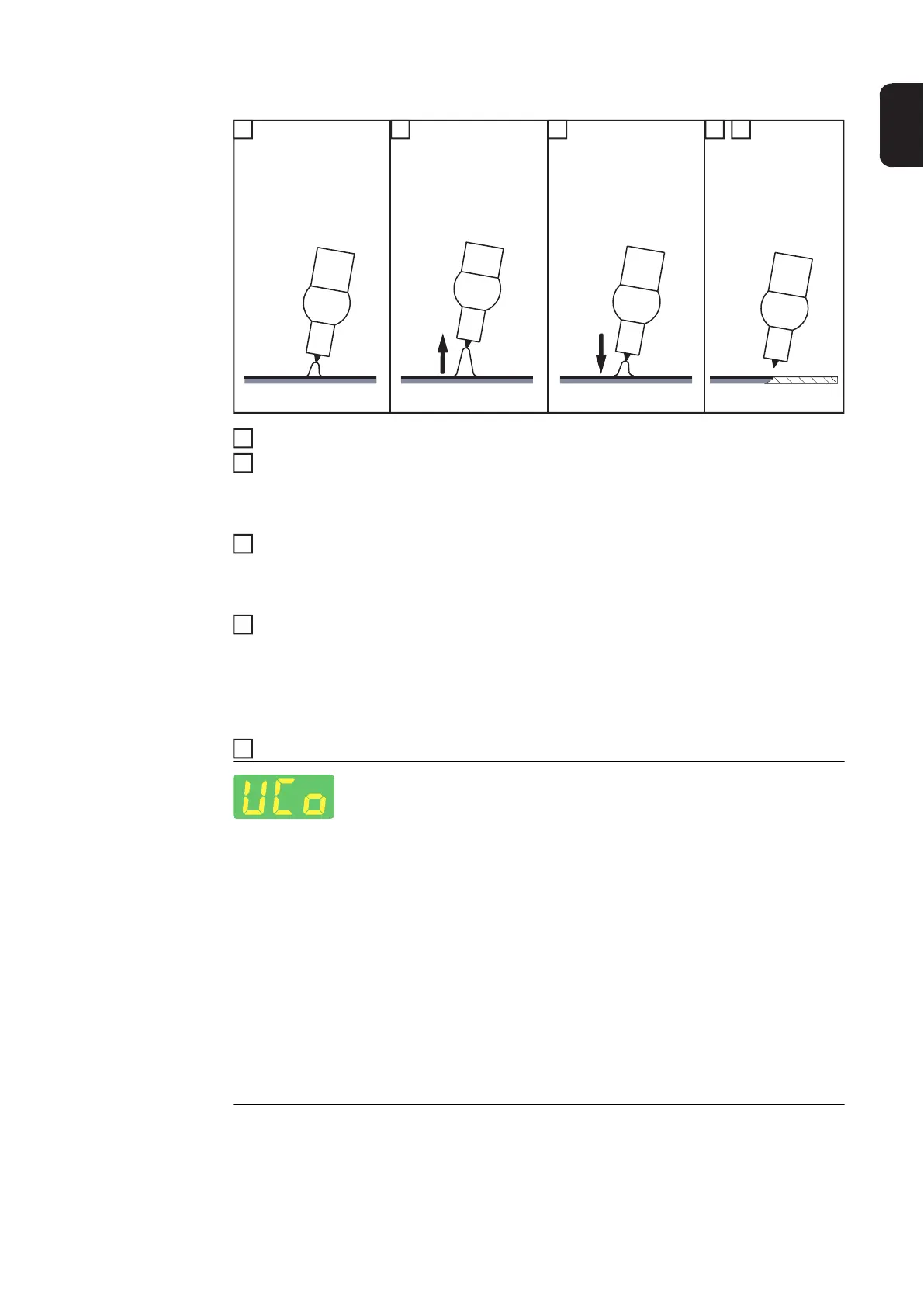

Process:

Welding

Briefly lift the welding torch at the end of welding

The arc lengthens significantly.

Lower welding torch

- The arc shortens significantly

- The TIG Comfort Stop function has triggered

Maintain height of the welding torch

- The welding current continuously ramps down (DownSlope).

- The arc goes out.

IMPORTANT! The DownSlope is fixed and cannot be adjusted.

Lift welding torch from the workpiece

Break voltage

For setting a voltage value at which the welding process may be ended by slightly raising

the TIG welding torch.

The higher the break voltage value, the higher the arc can be raised.

The break voltage values for 2-step mode, 4-step mode, and operation with a foot-operat-

ed remote control are all stored together.

If the "tri" parameter (trigger - torch trigger operating mode) is set to "oFF", the values are

stored separately.

10 - 45 V

Factory setting: 35 V (for 2-step and 4-step mode and operation with a foot-operated re-

mote control)

Factory setting: 25 V (for trigger = oFF operation)

1

2

3

4 5

1

3

4

5

Loading...

Loading...