32

(9) Gas test button

for setting the required shielding gas flow rate on the gas pressure regulator

After pressing this button, gas flows for 30 seconds. Press the button again to stop

the gas flow prematurely.

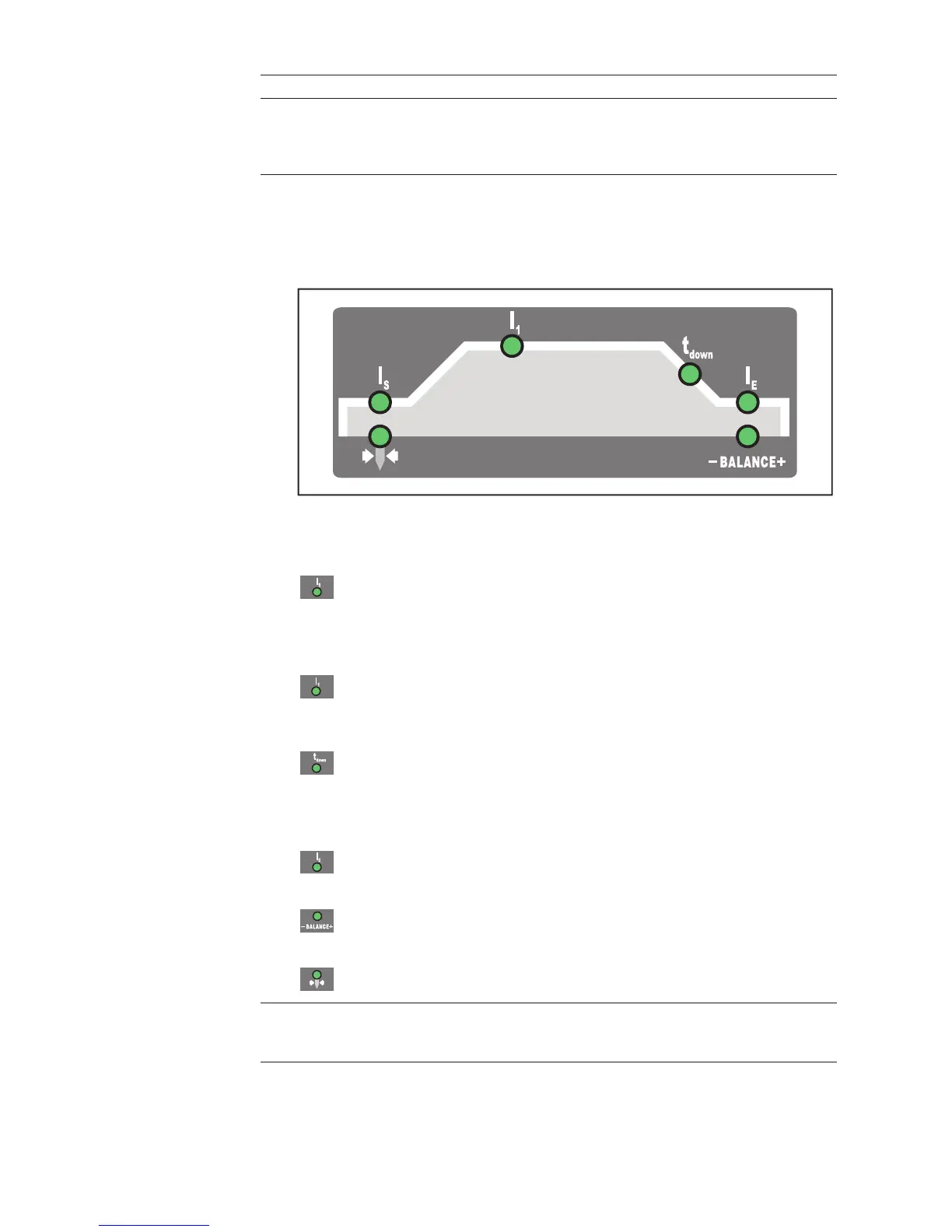

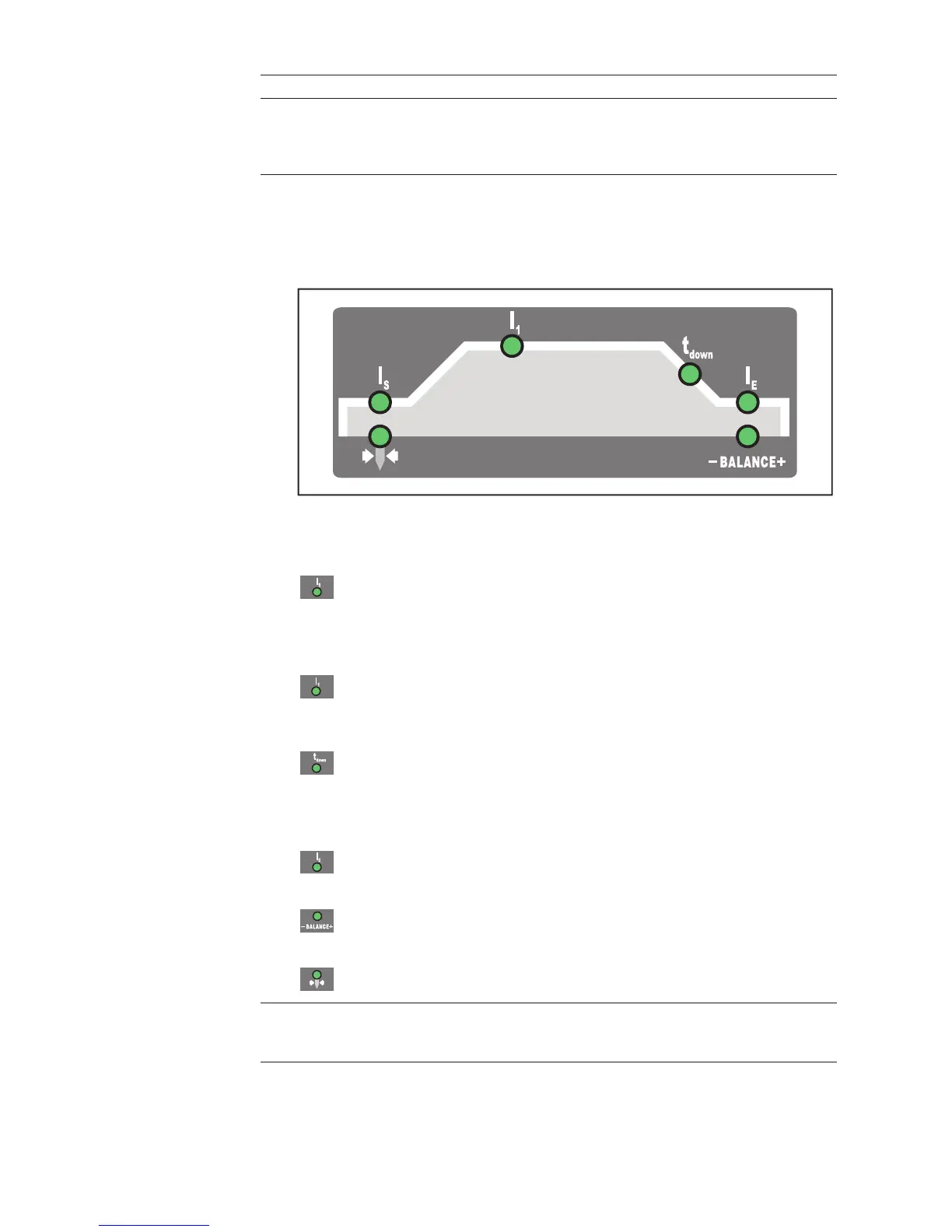

(10) Welding parameter overview

The welding parameters overview contains the most important welding parameters

to be used when welding. The sequence of welding parameters follows a clothes-

line structure. Use the left and right welding parameter selection buttons to navigate

within the welding parameters overview.

Welding parameters overview

The welding parameters overview contains the following welding parameters:

Starting current Is

for TIG welding

The starting current I

S

is saved separately for the "TIG AC welding" and "TIG DC- welding"

modes.

Main current I

1

(welding current)

- for TIG welding

- for MMA welding

Downslope t

down

when TIG welding, the period over which the current is decreased from the

main current I

1

to the final current I

E

The downslope t

down

is saved separately for 2-step and 4-step modes.

Final current I

E

for TIG welding

Balance

used to set the fusing power/cleaning action for TIG AC welding

Electrode diameter

Used in TIG welding to enter the diameter of the tungsten electrode.

(11) Adjusting dial

for altering welding parameters. If the indicator on the adjusting dial lights up, then

the selected welding parameter can be altered.

No. Function

Loading...

Loading...