En-7

5. FORMING THE DRAIN HOSE AND

PIPE

CAUTION

•Donotremovethearenutfromtheindoorunitpipeuntil

immediately before connecting the connection pipe.

•Topreventbreakingofthepipe,avoidsharpbends.

•If the pipe is bent repeatedly at the same place, it will

break.

[For

1

Rear piping,

2

Right piping and

3

Bottom piping]

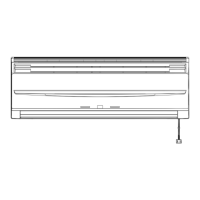

• Installtheindoorunitpipinginthedirectionofthewallhole

and bind the drain hose and pipe together with vinyl tape.

• Installthepipingsothatthedrainhoseisatthebottom.

Pipe (Top)

Cloth tape

2

Right piping

3

Bottom piping

Bind with vinyl tape

Drainhose(Bottom)

1

Rear piping

CAUTION

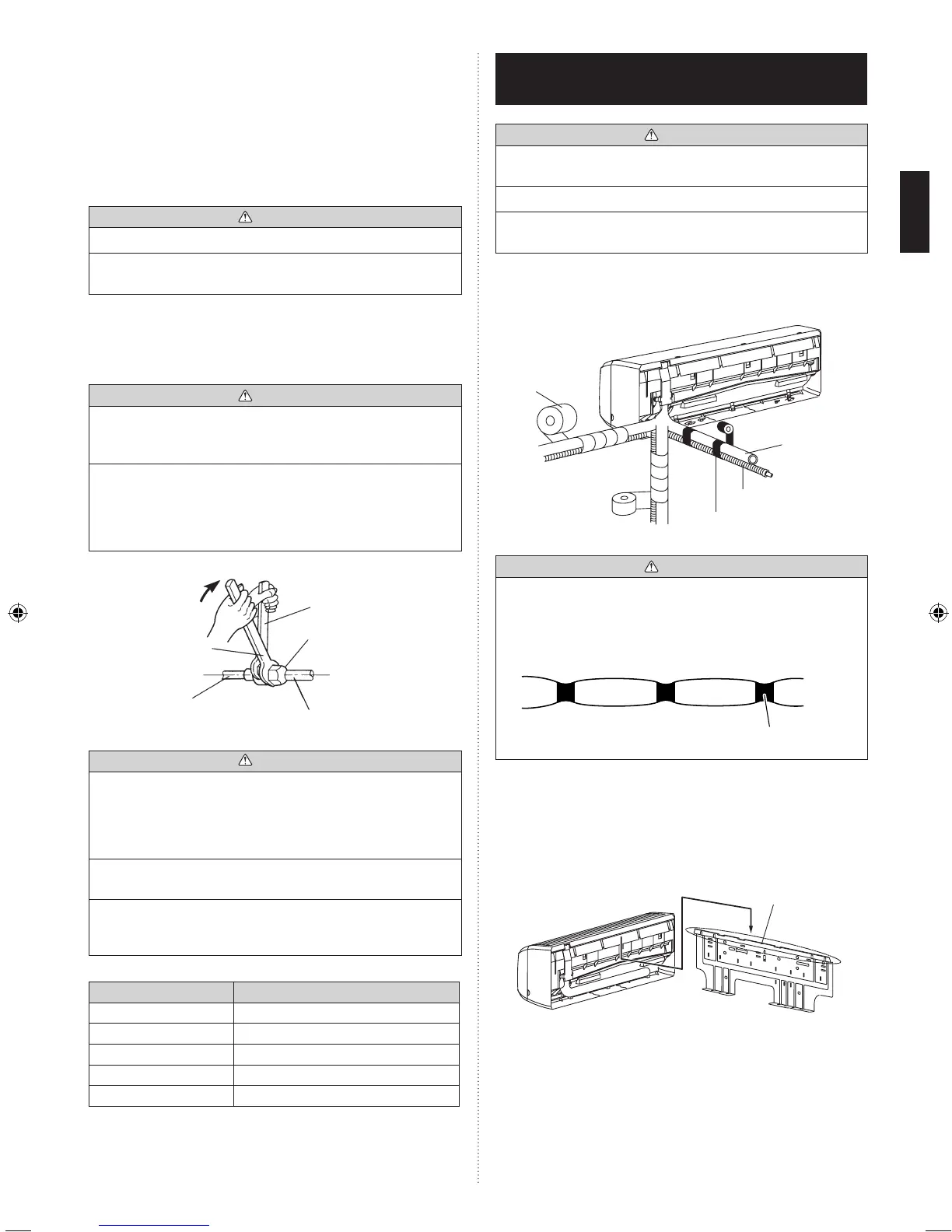

•Do not wrap the tape too tightly on drain hose. If the

tape is too tight (as shown in the Figure below) the

insulation effect will be lost and the moisture from

condensation may accumulate.

Bad Example

Vinyl tape too tight

• Perform“6.ELECTRICALWIRING”beforeperformingthis

piping.

• Wrapthepipesoftheindoorunitthatarevisiblefromthe

outside with cloth tape.

• Afterpassingtheindoorpipinganddrainhosethroughthe

wall hole, hang the indoor unit on the hooks at the top of the

wall hook bracket.

Wall hook bracket

Indoor unit

Top hooks

[For

4

Left rear piping,

5

Left piping and

6

Center

piping]

• Presettheendofthepipe.

• For

4

Left rear piping and

6

Center piping, route the

connection pipes through the wall.

• Bendtheconnectionpipingtoabendradiusnotlessthan

100 mm and position the piping no more than 50 mm from

the wall.

4.3.2. Bending pipes

The pipes are shaped by your hands or pipe bender. Be •

careful not to collapse them.

Donotbendthepipesinananglemorethan90°.•

When pipes are repeatedly bend or stretched, the material •

willharden,makingitdifculttobendorstretchthemany

more.Donotbendorstretchthepipesmorethanthree

times.

CAUTION

•Topreventbreakingofthepipe,avoidsharpbends.

•If the pipe is bent repeatedly at the same place, it will

break.

4.3.3. Pipe connection

Whenthearenutistightenedproperlybyyourhand,hold

the body side coupling with a separate spanner, then tighten

with a torque wrench.

CAUTION

•Holdthetorquewrenchatitsgrip,keepingitintheright

angle with the pipe, in order to tighten the flare nut

correctly.

•Tighten the flare nuts with a torque wrench using the

specified tightening method. Otherwise, the flare nuts

could break after a prolonged period, causing refrigerant

to leak and generate a hazardous gas if the refrigerant

comesintocontactwithaame.

Connection pipe

Torque wrench

Indoor unit pipe

(Body side)

Tighten with two wrenches.

Holding wrench

Flare nut

CAUTION

•Besuretoapplythepipeagainsttheportontheindoor

unit and the outdoor unit correctly. If the centering is

improper, the flare nut cannot be tightened smoothly.

If the flare nut is forced to turn, the threads will be

damaged.

•Donotremovethearenutfromtheindoorunitpipeuntil

immediately before connecting the connection pipe.

•Do not use mineral oil on flared part. Prevent mineral

oil from getting into the system as this would reduce the

lifetime of the units.

Flare nut [mm (in.)] Tightening torque [N·m (kgf·cm)]

6.35 (1/4) dia. 16 to 18 (160 to 180)

9.52 (3/8) dia. 32 to 42 (320 to 420)

12.70 (1/2) dia. 49 to 61 (490 to 610)

15.88 (5/8) dia. 63 to 75 (630 to 750)

19.05 (3/4) dia. 90 to 110 (900 to 1,100)

Loading...

Loading...