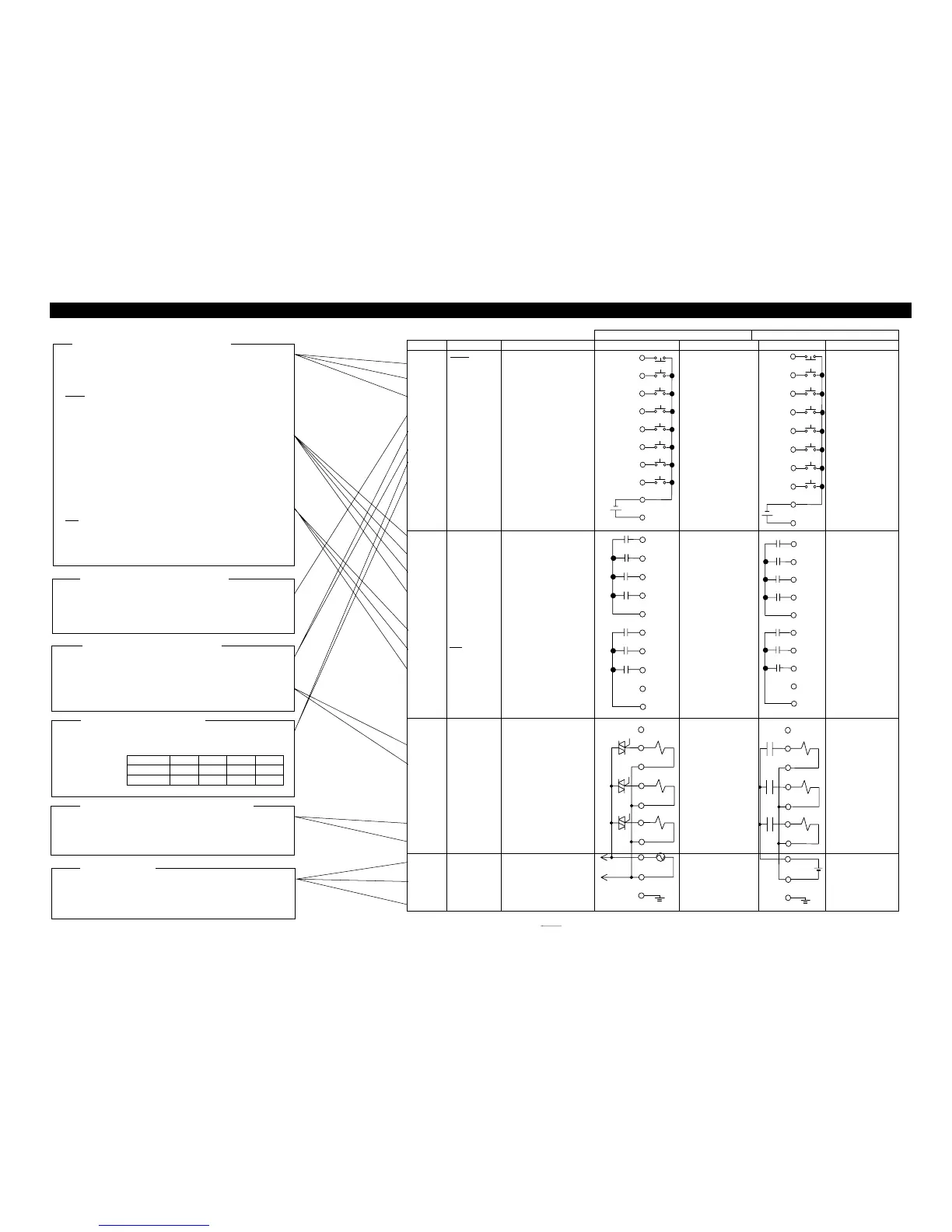

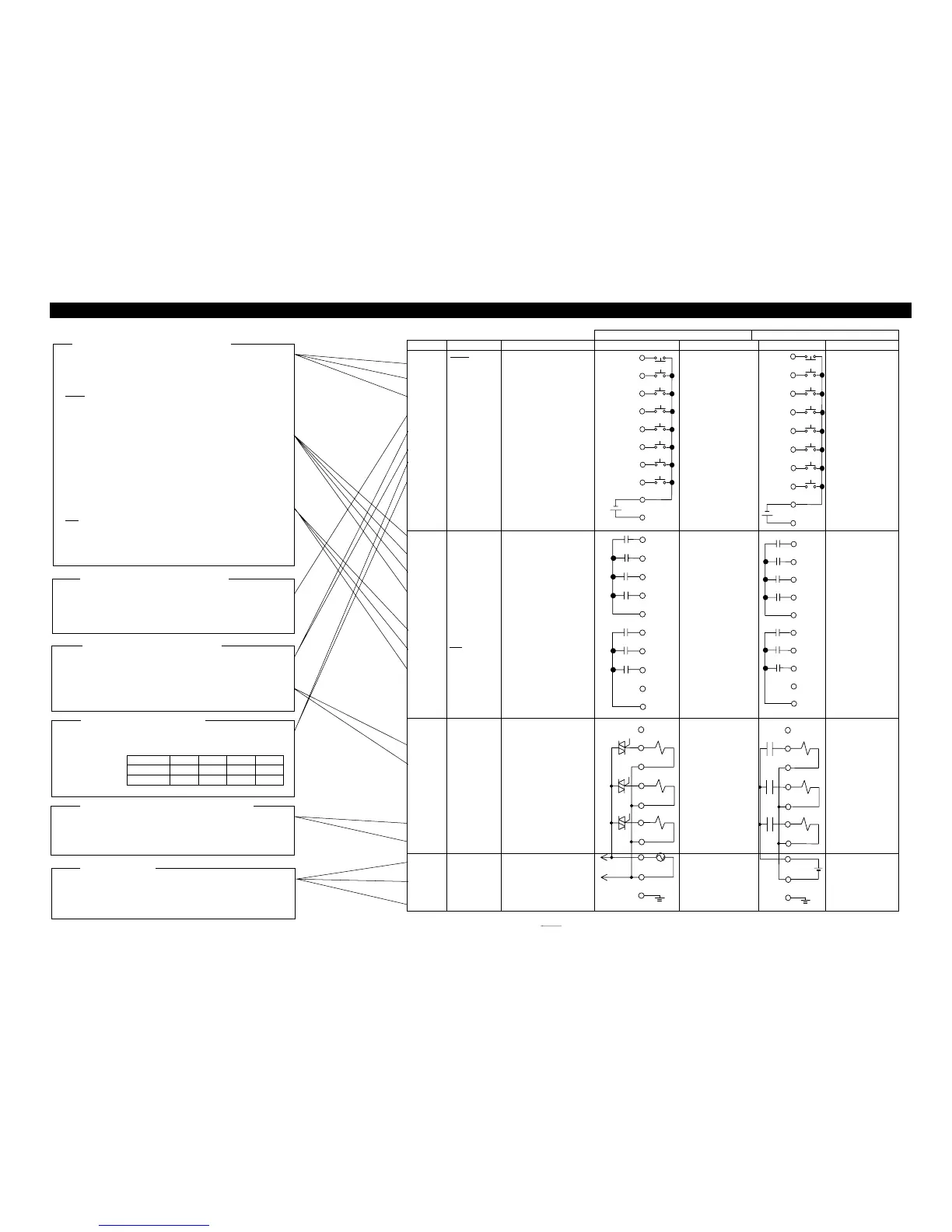

ELECTRIC WIRING CONFIGURATION

Control testing and bubble testing procedures

・ START Start of air leak test.

Applies a pulse signal of 0.5 sec or longer during DLY sequence.

・BUBL Start of bubble test

Performs a bubble test while a signal is being applied.

・RESET Stop the tester in case of an emergency.

Apply a break signal to open the air circuit. The RDY sequence

is established after EXH sequence.

Test result output

・OK -NG set range < leak reange < +NG set range

・+NG leak reange ≧ +NG set range

・-NG -NG set range ≧ leak reange

・P.NG Test pressure is lower than the set value at the end of

PRES sequence.

・P.NG Test pressure is lower than the set value set up with

P.SW at time of BAL sequence.

Current status output

・RDY Standby (Ready Status)

・ERR Error has transpired.

When the power is OFF, ERR can be used to confirm

ON/OFF status.

・END Testing has ended.

*1 The air leak tester’s internal output status: power off.

*2 The names, indicated with line(***)imply that the signal is effective when it is open. 19

Controlling clamping cylinders

・LMT 1 Input of unclamp signals

・LMT 2 Input of clamp signals

・SOL 1 Cylinder Driving valve control signals

※

In the Internal Operation Mode, the tester cannot operate.

Specifies the Group # (0~3)

・ CH1

・ CH2

Group # selection

0 1 2 3

CH1 ○ ● ○ ●

CH

○ ○ ● ●

○:Open ●:Short

Controls the exhaust bypass unit

SUPPLIES POWER TO THE AIR LEAK TESTER

Apply power voltage specified by the manufacture

・F.G Be sure to ground this terminal.

EXHAUST BYPASS UNIT CONTROL SIGNALS

POWER SUPPLY

GROUP SWITCHING SIGNALS

CYLINDER CONTROL SIGNALS

Pressure Error (P.NG) Verification Signal Input

・P.SW Pressure switch signal input.

If pressure verification function is not used,

keep the P.SW pin connected to the COM- pin.

PRESSURE VERIFICATION SIGNALS

AIR LEAK TESTER CONTROL SIGNAL

z REMOTE TERMINAL BOARD

FL-

Loading...

Loading...