AIR PIPE CONFIGURATIONS

☆ Air leak testers are designed to detect a leak by sensing a small change in pressure.

For that reason, you must ensure that the air leak tester’s piping differs from normal piping.

Please keep this in mind to help obtain accurate and reliable leak testing.

☆

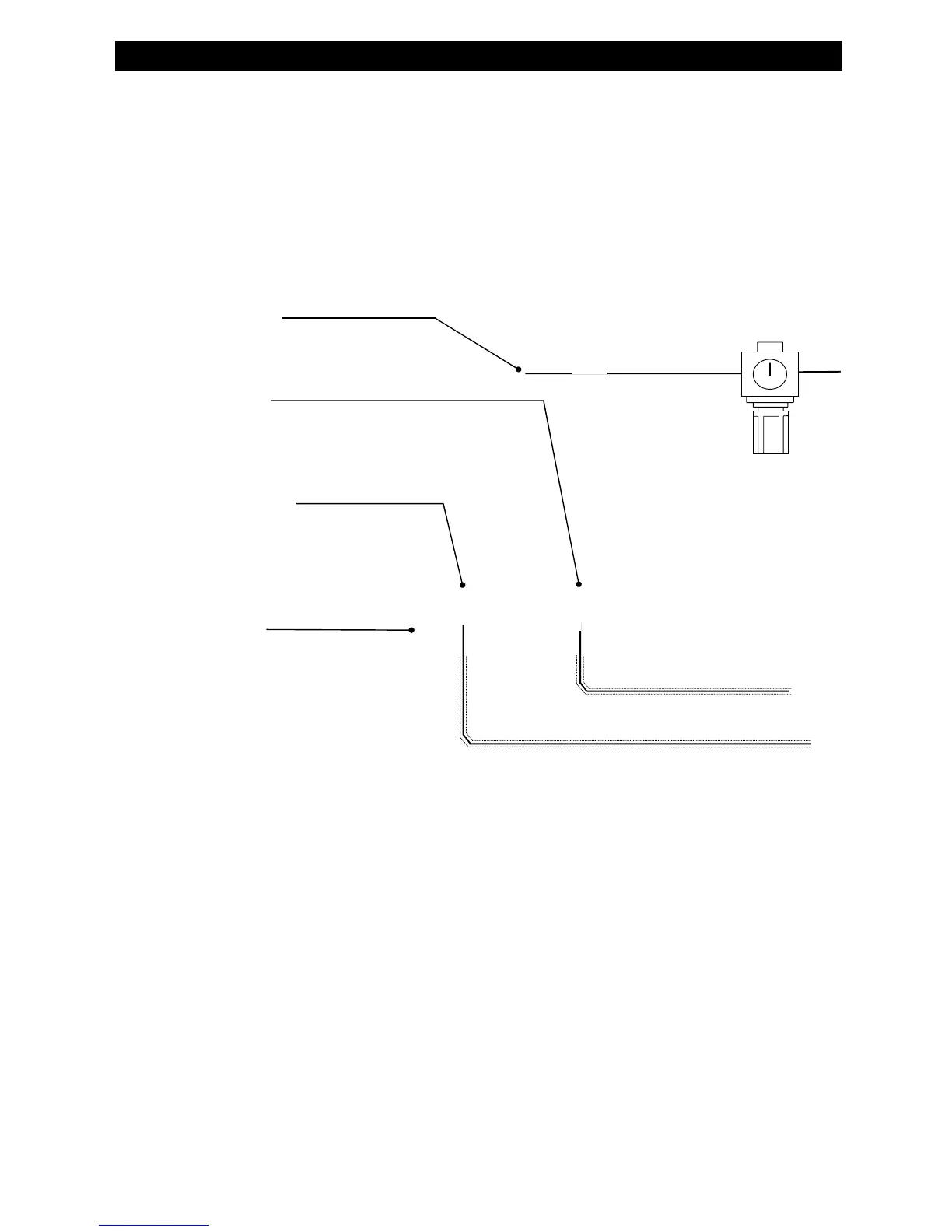

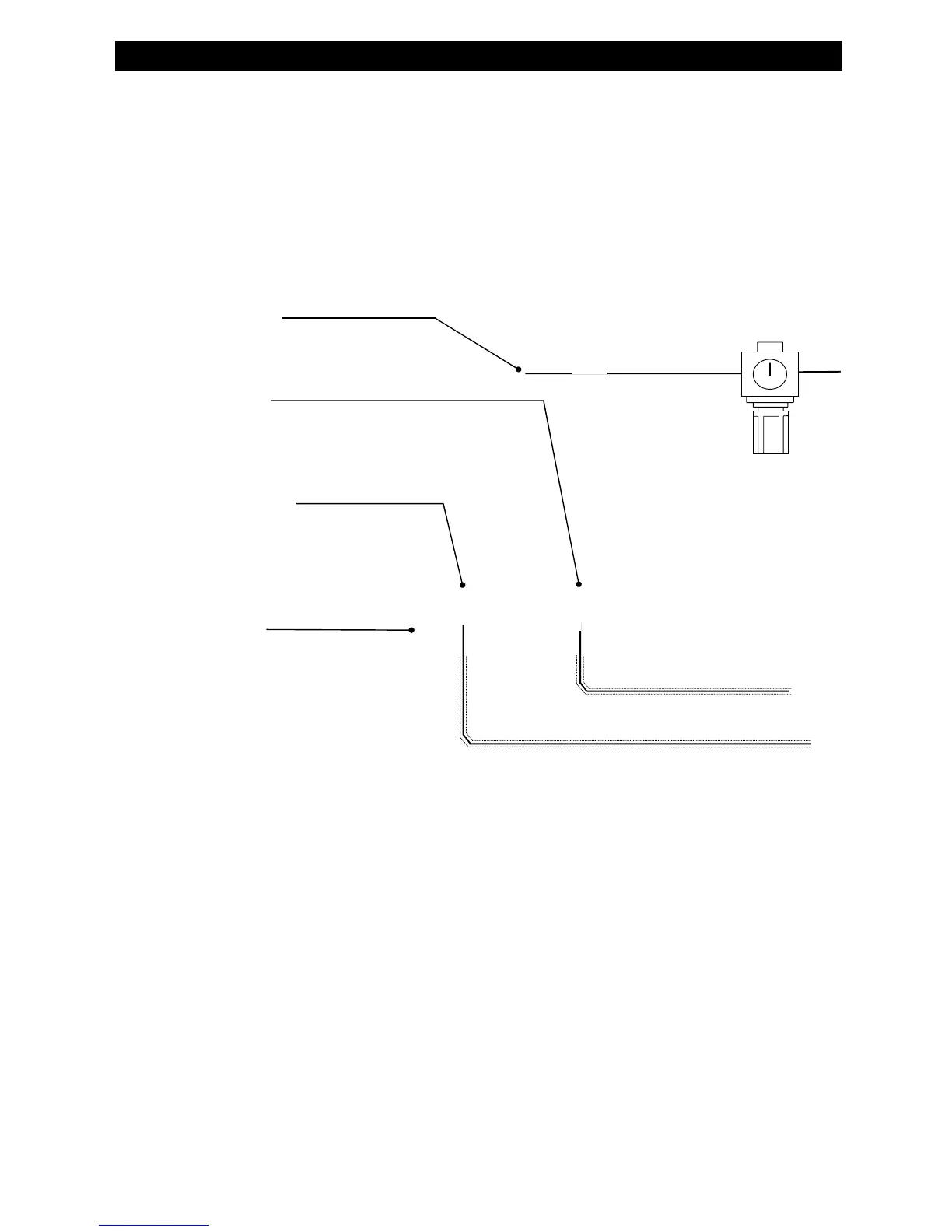

TEST CIRCUIT PIPES

For the test circuit piping, it is necessary to use rigid, leakless pipes that will not change in size and

configuration under applied pressure.

For connection, use a high-pressure type coupler.

Arrange them to minimize thermal effect.

Keep them away from heat generating elements such as solenoid valves.

Keep the piping arrangement as short as possible.

Wrap them with thermal insulation material.

(e.g. Spiral Tubes)

Others

Stabilize the piping to avoid unnecessary movements during measurement.

Allow “MASTER” and “WORK” piping to provide the same conditions.

Do not connect inappropriate items to the testing piping.

Make sure you always use the optional pressure switch which checks the internal

pressure of the work, if the equipment is used with a pressure of 10 kPa or lower.

PRIMARY PRESSURE

REGULATOR

Adjust to: (approx.)

Test pressur

Loading...

Loading...