ELECTRICAL AND AIR PIPE LINE CONNECTIONS

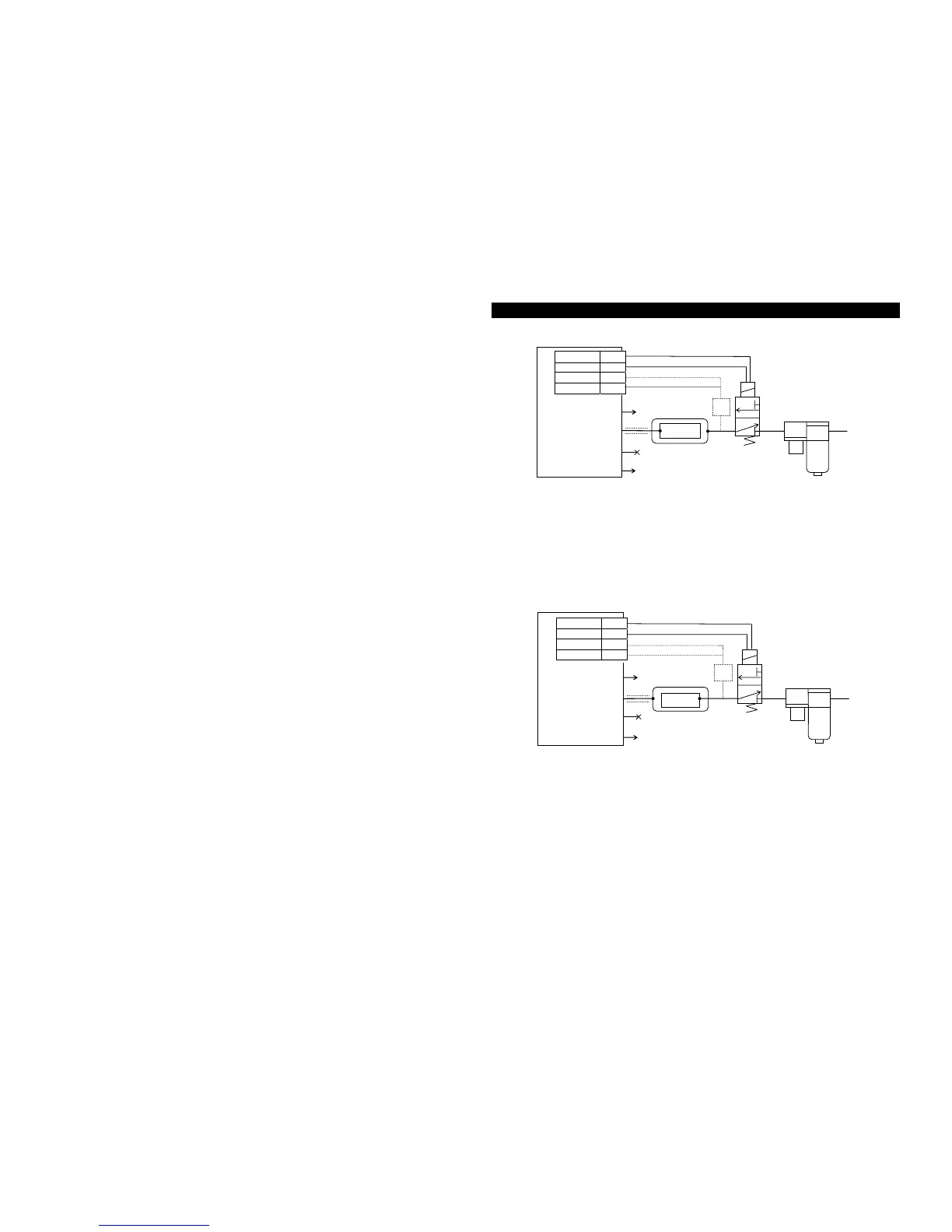

■ CONNECTION FOR LEAK SIDE TESTING (Outside Pressure Method)

Air Leak Tester

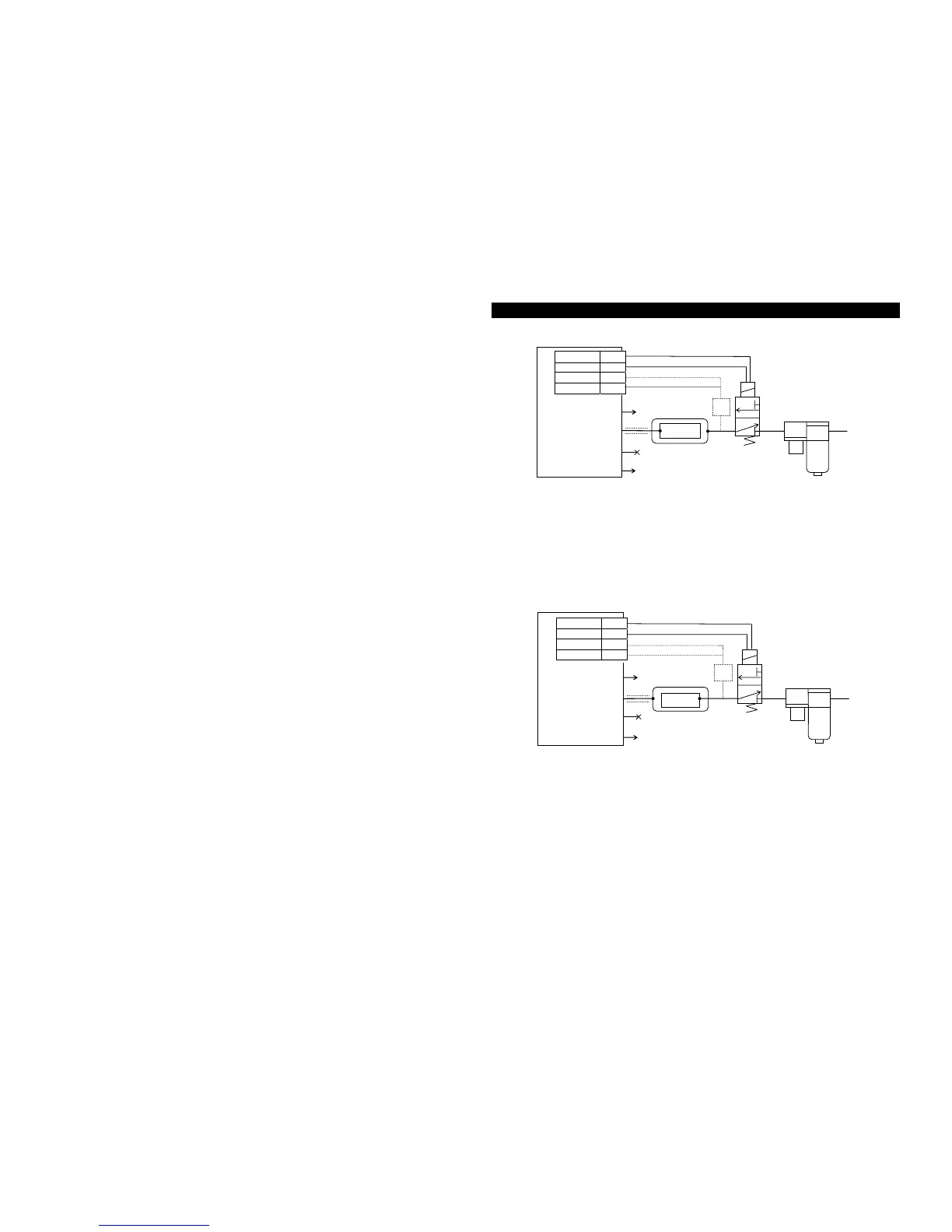

■ CONNECTION FOR LEAK SIDE TESTING (Internal Pressure Method)

Air Leak Tester

20

Work

AIR.SUP

WORK

MASTER

EXH

SOL2 29

SOL2 30

P.SW 4

COM- 9・10

CAPSULE 3-WAY VALVE

OPEN TO ATMOSPHERE

◎

COMPRESSED

AIR SOURCE

TESTPRES.REGULATOR

①

AIR.SUP

WORK

MASTER

EXH

SOL2 29

SOL2 30

P.SW 4

COM- 9・10

CAPSULE 3-WAY VALVE

TEST PRES. REGULATOR

rk

◎

COMPRESSED

AIR SOURCE

①

OPEN TO ATMOSPHERE

● SPECIFICATION REQUIREMENTS FOR 3-WAY VALVE SHOWN IN THE FIGURE ABOVE

Driving Voltage : FL-2□□□-0:AC100V 50/60HZ

FL-2□□□-2:To accord with external valve power source specs.

Power consumption : Less than 100VA

Valve Type : Commercially available valves for cylinder drives can be applied.

(Non-lubricate type)

Valve Size : In accordance to capsule volume

● The test pressure can be checked with a pressure switch (locate ① on the figure above).

● For connection details, refer to page 23.

● If there is a leak from the capsule due to clamping inefficiency, the leak from the Work may not be detected. In

such cases, carry out a test by connecting the master and adding minute pressure to the AIR. SUP port. This

procedure aids in the detection of clamping inefficiencies. *1. The minute pressure added to the AIR SUP port

should be largely different from the test pressure.

● In the figure above, →implies open to atmosphere, and ×means manual valve closed or closed with some kind of

plug.

*1: If performing a leak test by adding pressure, please ensure that the pressurized air enters the failure work

and that you use an inverse polarity.

If the inspection is executed under negative test pressure, the polarity will not be reversed.

● SPECIFICATION REQUIREMENTS FOR

-WAY VALVE ARE SHOWN IN THE FIGURE ABOVE

Driving Voltage : FL-2□□□-0:AC100V 50/60HZ

FL-2□□□-2:To accord with external valve power source specs.

Power consumption : Less than 100VA

Valve Type : Commercially available valves for cylinder drives can be applied.

(Non-lubricate type)

Valve Size : In accordance with capsule volume.

● The test pressure can be checked with a pressure switch (locate ①on the figure above).

For connection details, refer to page 23.

● In the figure above, →implies open to atmosphere, and ×means manual valve closed or closed with some

kind of plug.

Loading...

Loading...