4 THROUGH FAULT MONITORING

Through faults are a major cause of transformer damage and failure, as they can stress the insulation and

mechanical integrity of the transformer

. Through-fault monitoring is usually used to tackle this problem. This

mechanism monitors fault currents passing through the transformer, which may significantly exceed its rated

current. The through-fault monitoring mechanism is based on an I

2

t calculation.

According to IEEE C57.109-1993(R2008), mechanical effects are more significant than thermal effects for fault-

current magnitudes near the design capability of the transformer. However, at fault-current magnitudes close to

the overload range, mechanical effects are less important unless the frequency of fault occurrence is high. Note

that mechanical effects are more important in large kVA transformers. The standard states that the maximum

duration limit for the worst case of mechanical duty is 2 s.

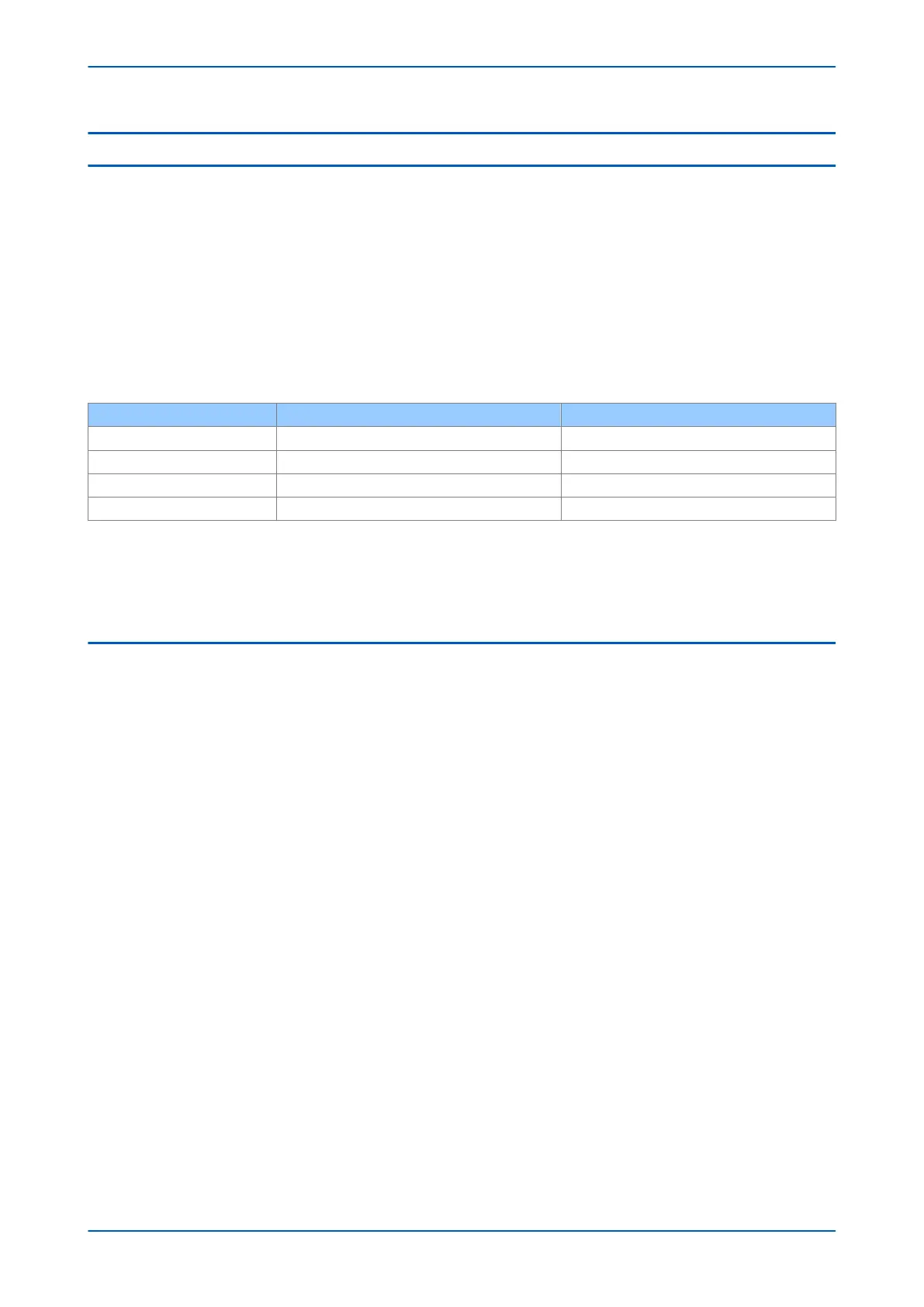

The standard defines the following transformer categories:

Category Single phase (kVA) Three-phase (kVA)

I 5 to 500 15 to 500

II 501 to 1667 501 to 5000

III 1668 to 10000 5001 to 30000

IV Above 10000 Above 30000

Categories I and II consider only the transformer short-circuit impedance, whereas categories III and IV consider

the system short-circuit impedance at the transformer location as well as transformer short-circuit impedance.

The short-circuit impedance is expressed as a percentage of the transformer rated voltage and the rated power of

the transformer.

4.1 THROUGH FAULT MONITORING IMPLEMENTATION

Through-fault monitoring can be enabled with the Thr

ough Fault setting in the TF MONITORING column.

The through-fault current monitoring function monitors the fault current level, the duration of the faulty condition

and the date and time for each through-fault. An I

2

t calculation based on the recorded time duration and

maximum current is performed for each phase.

This calculation is only performed when the current exceeds the TF I> Trigger setting and if the DDB signal Any

Diff Start is NOT asserted. Cumulative stored calculations for each phase are monitored so you can schedule the

transformer maintenance based on this data.

A single-stage alarm is available for through-fault monitoring. The alarm is issued if the maximum cumulative I

2

t in

the three phases exceeds the TF I2t> Alarm setting. A through fault event is recorded if any of the phase currents

is larger than the TF I> Trigger setting. You should always set TF I> Trigger greater than the overload capability of

the transformer.

Chapter 7 - Transformer Condition Monitoring P64x

154 P64x-TM-EN-1.3

Loading...

Loading...