checkbox to have your object printed with support structures.

b. Extruder

If you are printing with dual extruder, you can select one of them to print the support

material.

c. Pattern

There are different patterns available for printing support structures, resulting in sturdiness or

the easiness to remove the support. You can choose from the following patterns.

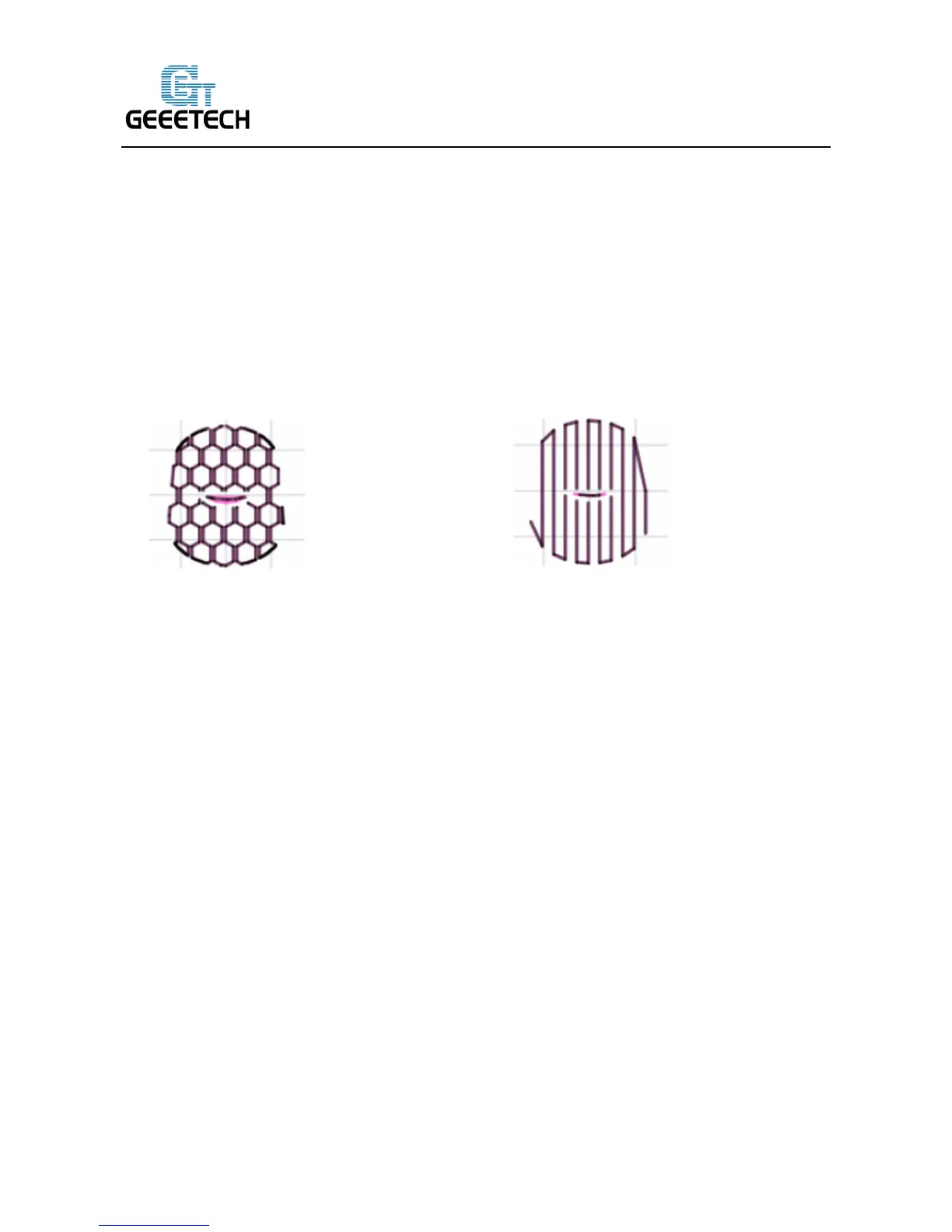

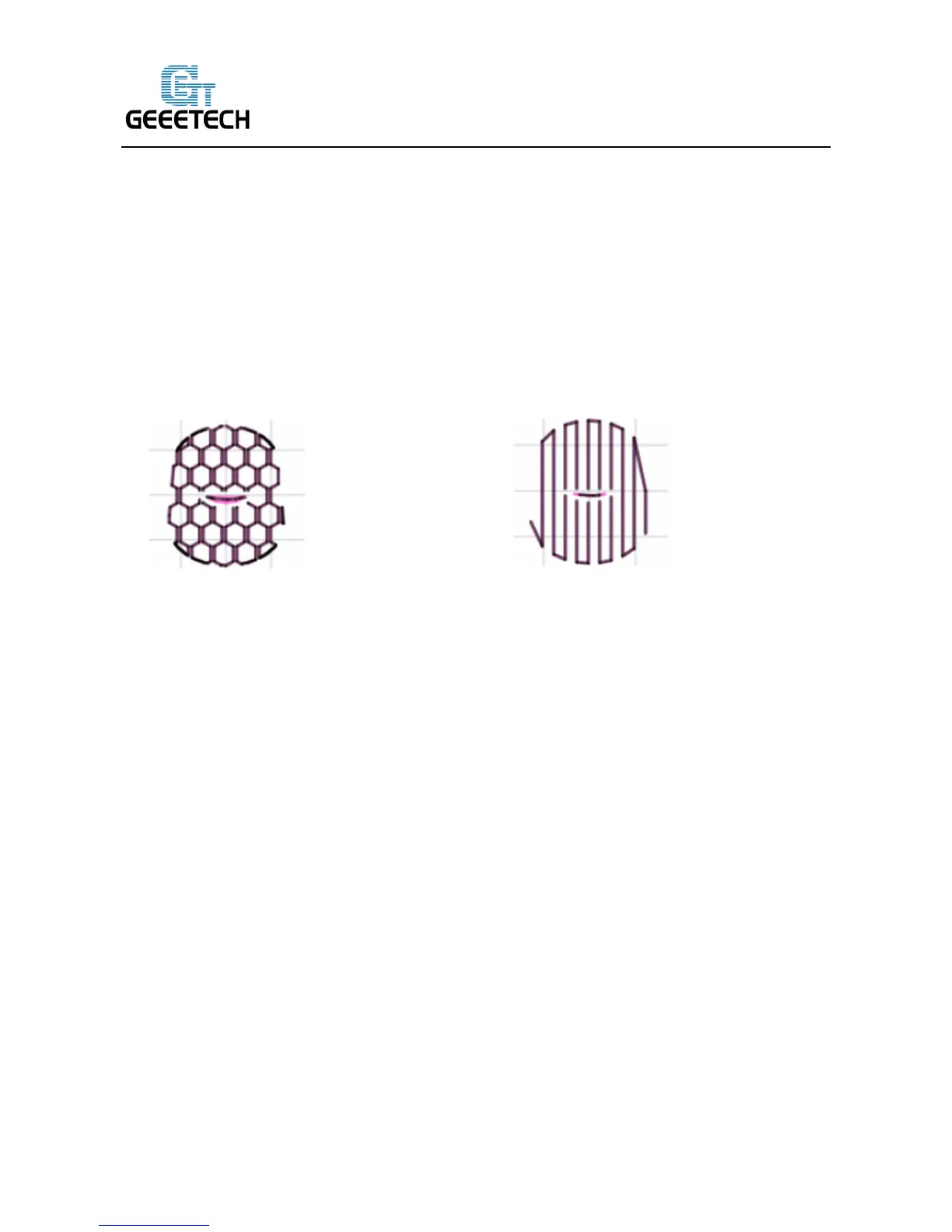

(1) Honeycomb (2) Rectilinear

d. Pattern Spacing

Pattern Spacing determines the distance between support lines, and is akin to infill density

apart from being defined only in mm. The adjustment of this attribute by taking into account the

width of the support extrusion and the amount of support material will adhere to the object.

Care should be taken to choose a support pattern which matches the model, where the support

material attaches perpendicularly to the wall of the object, rather than in parallel, so it will be easy

to remove. If the support structure does run along the length of a wall, the Pattern Angle option

allows the direction of the support lines to be rotated.

Now all the parameters are set. Click [Apply] and [OK].

4. Begin Printing

So far, all the preparatory work is completed. The next step is to import the model file for slicing

and printing. For 3D printer, the file format of the model is generally .stl file. We can download for

free and print those models which are shared online, and you can also design your own creative

Loading...

Loading...