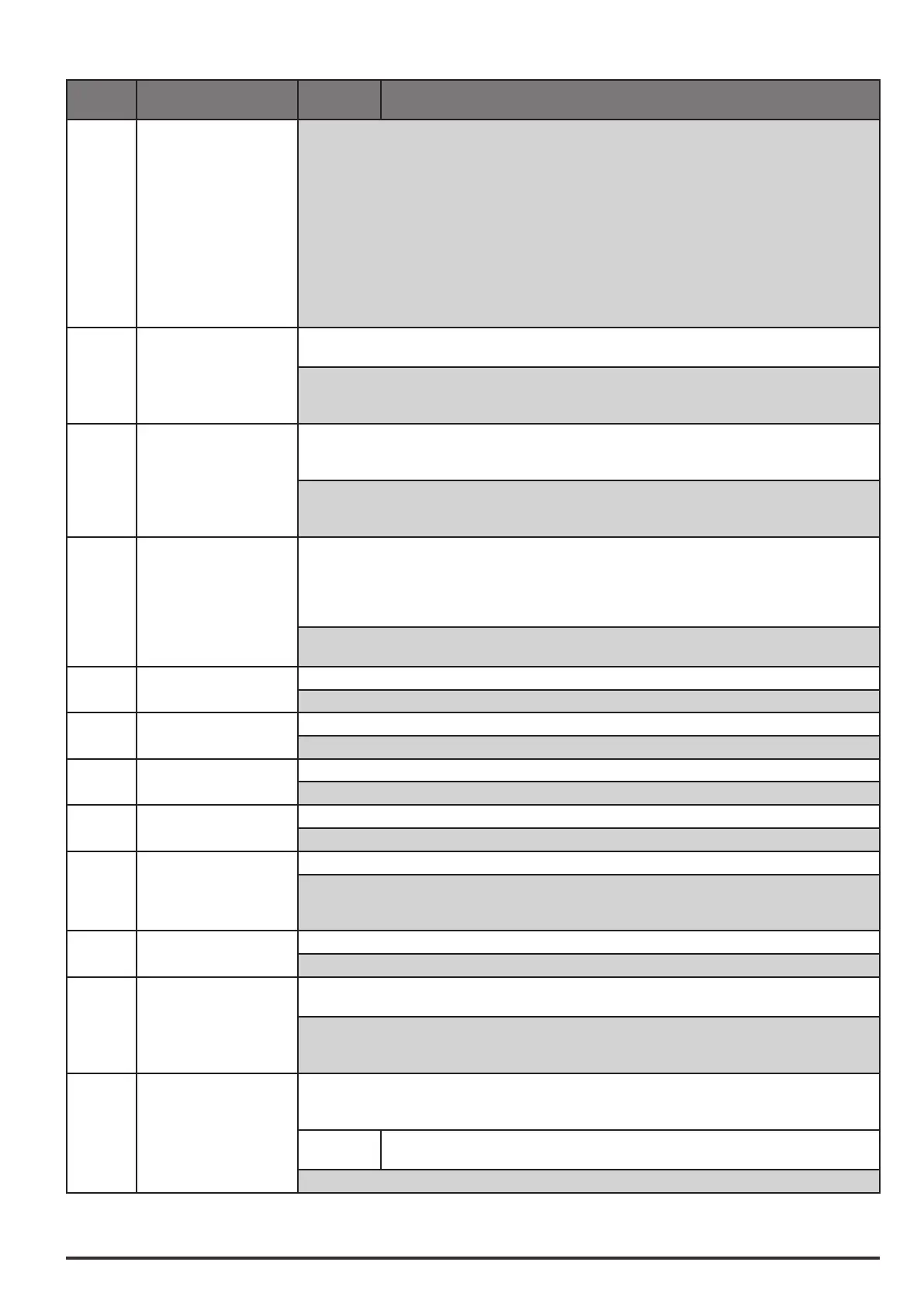

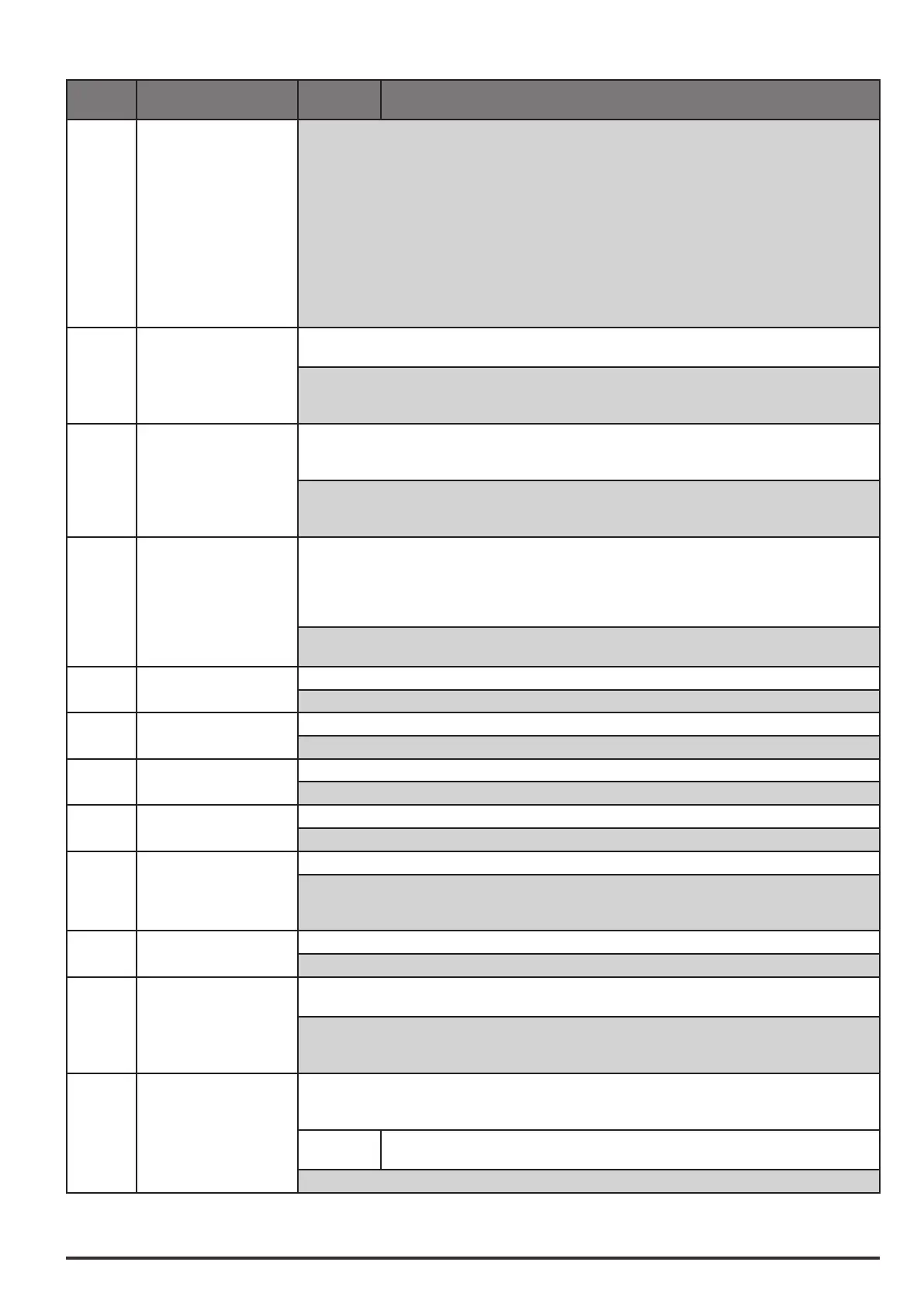

ADV200 • Troubleshooting 201

Code Error message shown on

the display

Sub-code Description

Solution:

- Check encoder wiring for integrity.

- Check that the encoder is connected to the power supply.

- With the drive disabled, turn the motor clockwise (seen from the motor shaft side). A positive value must

be displayed.

- If the value does not change or values are indicated randomly, check the encoder power supply and

cables.

- If the value displayed is negative, invert the encoder connections. Change channel A+ and A- or B+ and B-.

- Check that the encoder electronics are consistent with those of the relative expansion card.

- Generated in case of an encoder fault. Each type of encoder generates a “Loss of feedback” alarm differ-

ently. See parameter 2172 SpdFbkLoss code for information about the cause of the alarm and chapter C.1

Speed fbk loss alarm.

23 Overspeed

Condition: Motor overspeed alarm.

The motor speed exceeds the limits set in the PAR 4540 Overspeed threshold parameter.

Solution:

- Limit the speed reference.

- Check that the motor is not driven in overspeed during rotation.

24 Speed ref loss

Condition: Speed reference loss alarm; occurs if the difference between the speed regulator reference

and the actual motor speed is more than 100 rpm. This condition occurs because the drive is in the current

limit condition. It is only available in the Flux Vect OL and Flux Vect OC mode.

Solution:

- Check the drive load conditions

- Check the number of encoder impulses

25 Emg stop alarm

Condition: Emergency stop alarm.

The Stop key on the keypad was pressed with the PAR 1008 Stop key mode parameter set to

EmgStop&Alarm.

Active in remote control mode (PAR 1012=1) both by using “Terminals” command or “Digital” commands

and, in local control mode (PAR 1012=0) by using “Terminals” command.

Solution:

Eliminate the reason for which the Stop key on the keypad was pressed and reset the drive.

26 Power down Condition: The drive was enabled with no supply voltage at the power section.

Solution: Check the drive power supply

27 ExtIO fault Condition: Communication fault with the external module.

Solution: See paragraph “C-2 “ExtIO fault” Alarm” on page 210

28 FastLink fault Condition: FastLink communication fault

Solution: See paragraph “C-3 “Fastlink” Alarm” on page 211

29 Brake fault Condition: Incorrect setting of brake control function parameters.

Solution: See menu 22.13 - FUNCTIONS/BRAKE CONTROL

30 Motor pre OT Condition: Motor overtemperature prealarm. % value of threshold compared to PAR 4532 MotorOT thr,

Solution:

- Value set too low for duty cycle

- Heavy duty cycle

31 Mot phase loss Condition: Output phase loss.

Solution: Check Drive/motor connection.

32

Condensation

Condition: There may be problem of condensation inside the ADV200-LC drive series. Working condition

(combination of ambient temperature, Humidity level and temperature of the cooling liquid) is not safe,

Solution: Safe conditions are obtained when the work point is under the respective curve indicated in the

drawing of chapter 22.18 FUNCTION/LC CONTROL. Otherwise, you have to take adequate precautions to

lower the ambient tempera ture and/or the relative humidity or to raise the cooling liquid temperature.

33 ... 40

Plc1 fault

...

Plc8 fault

Condition: Enabled application developed in the IEC 61131-3 environment has found the conditions for

generating this specific alarm to be true. The meaning of the alarm depends on the type of application. For

more information, refer to the documentation concerning the specific application..

XXXXH-X The XXXXH-X code indicates the reason for the error: make a note of this to discuss it with

the service centre.

Solution: Refer to the documentation concerning the enabled application.

Loading...

Loading...