33 / 44

554

Installation:

1. Ensure the suitability of the valve for

each respective use. The valve must

be appropriate for the piping system

operating conditions (medium, medium

concentration, temperature and

pressure) and the prevailing ambient

conditions. Check the technical data of

the valve and the materials.

2. Shut off plant or plant component.

3. Secure against recommissioning.

4. Depressurize the plant or plant component.

5. Completely drain the plant (or plant

component) and let it cool down until

the temperature is below the media

vaporization temperature and scalding

can be ruled out.

6. Correctly decontaminate, rinse and ventilate

the plant or plant component.

Installation - Butt weld spigots:

1. Adhere to good welding practices!

2. Disassemble the actuator before welding the

valve body into the pipeline (see chapter

12.1).

3. Allow butt weld spigots to cool down.

4. Reassemble the valve body and the actuator

(see chapter 12.3).

Installation - Flange connection:

Install the valve in the condition it is

delivered in:

1. Pay attention to clean, undamaged sealing

surfaces on the mating fl anges.

2. Align fl anges carefully before installing them.

3. Centre the seals accurately.

4. Use all fl ange holes.

5. Connect the valve fl ange and the piping

fl ange using appropriate sealing material

and matching bolting (sealing material

and bolts are not included in the scope

of the delivery).

Tighten the bolts diagonally!

6. Only use connector elements made of

approved materials!

Installation - Clamp connections:

G When assembling clamp connections,

insert a gasket between the body clamp

and the adjacent piping clamp and join

them using the appropriate clamp fi tting.

The gasket and the clamp for clamp

connections are not included in the scope

of delivery.

Installation - Threaded connections:

G Screw the threaded connections into the

piping in accordance with valid standards.

G Screw the valve body into the piping, use

appropriate thread sealant. The thread

sealant is not included in the scope of

delivery.

Observe appropriate regulations for

connections!

After the installation:

G Reactivate all safety and protective

devices.

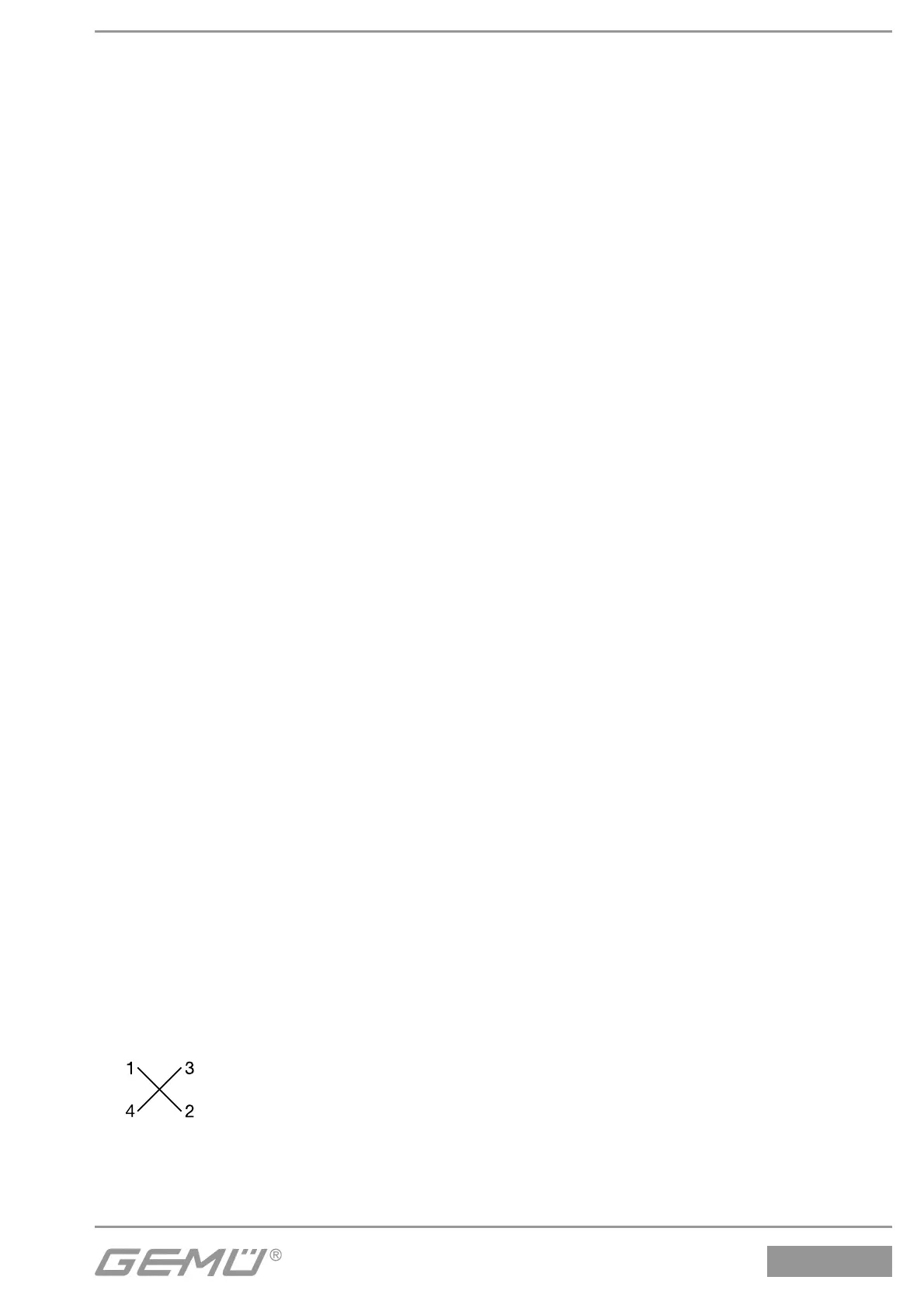

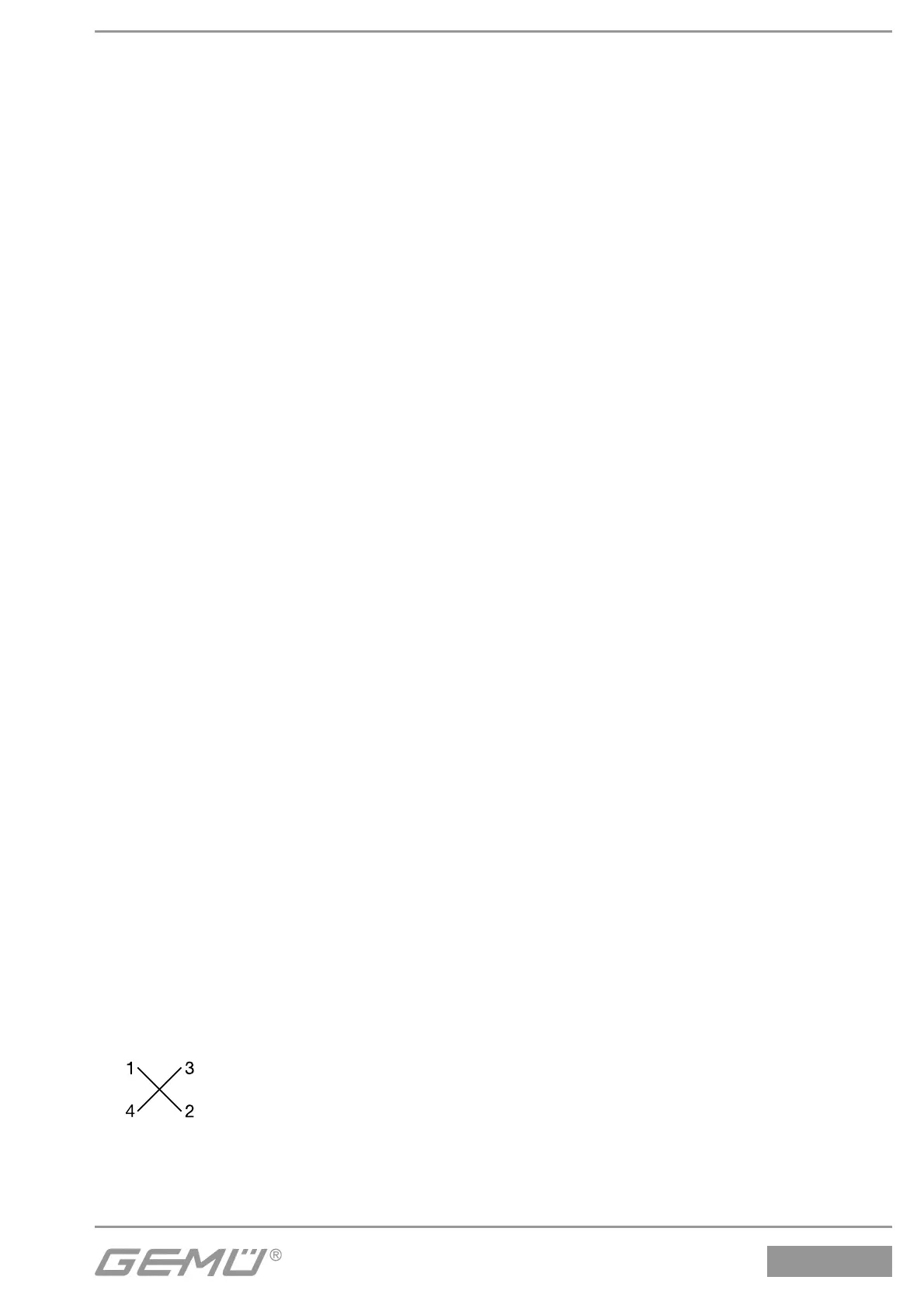

11.2 Control functions

The following control functions are available:

Control function 1

Normally closed (NC):

Valve resting position: closed by

spring force. Activation of the actuator

(connector 2) opens the valve. When the

actuator is vented, the valve is closed by

spring force.

Control function 2

Normally open (NO):

Valve resting position: opened by

spring force. Activation of the actuator

(connector 4) closes the valve. When the

actuator is vented, the valve is opened by

spring force.

Control function 3

Double acting (DA):

Valve resting position: no defined normal

position. The valve is opened and closed

by activating the respective control

medium connectors (connector 2: open /

connector 4: close).

Loading...

Loading...