35 / 44

554

12.2 Replacement of seals

Replacement of seat seal: not for

actuator size B.

Important:

Replace gasket 4 during every

actuator disassembly / assembly.

1. Disassemble actuator A as described in

chapter 12.1, points 1-4.

2. Remove gasket 4.

3. Loosen nut d on spindle b (hold spindle b

with appropriate tool that will not damage

the spindle surfaces). Remove washer e

and seat seal 14.

4. Clean all parts, do not scratch or damage

the parts during cleaning.

5. Insert new seat seal 14.

6. Insert washer e.

7. Apply appropriate mounting glue on the

thread of spindle b.

8. Fix with nut d (hold spindle b with

appropriate tool that will not damage the

spindle surfaces).

9. Insert new gasket 4 in valve body 1.

10. Assemble actuator A as described in

chapter 12.3, points 1-5.

12.3 Assembly of actuator

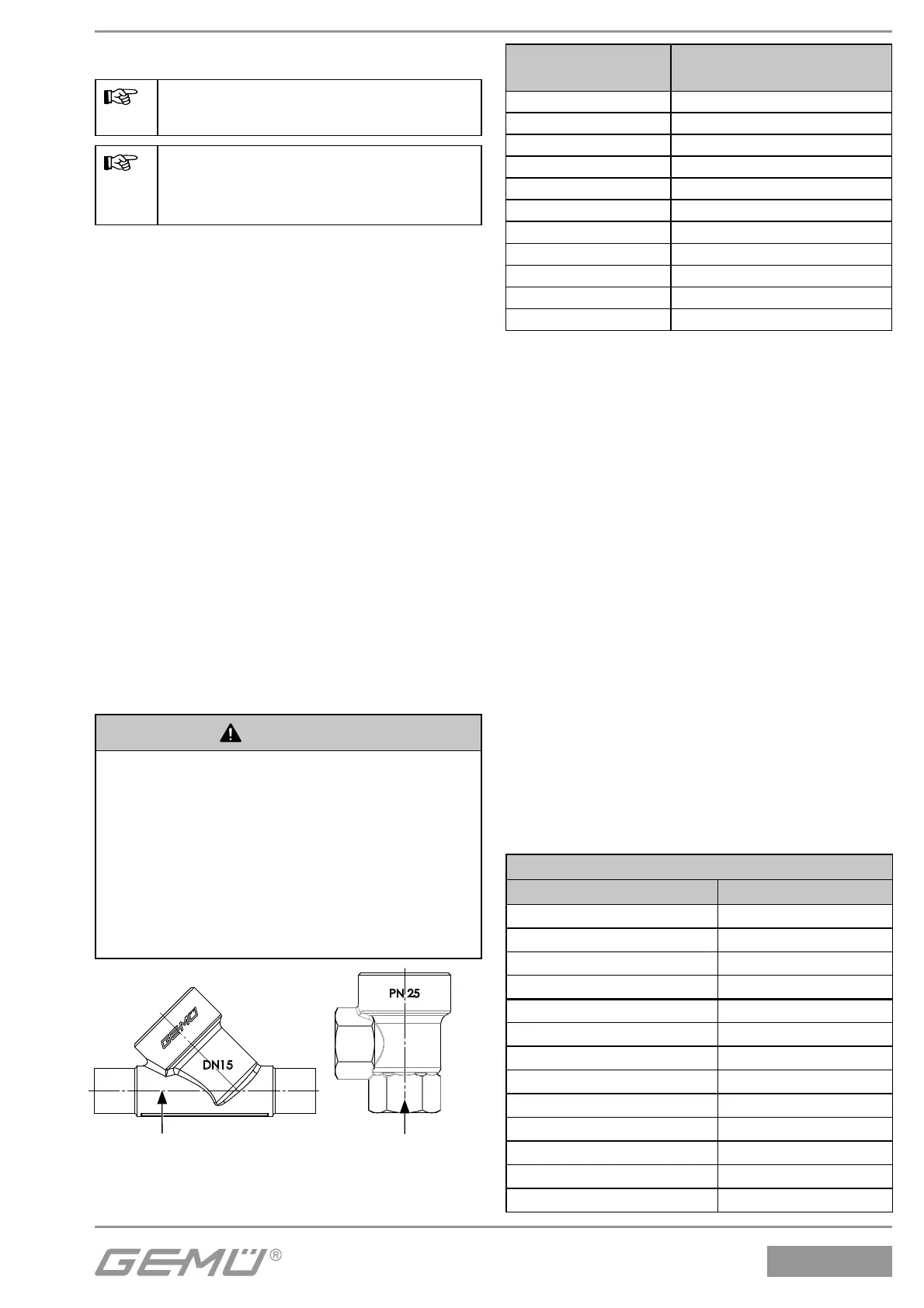

CAUTION

Correct combination of actuator and

valve body!

® Risk of damage to the actuator and

valve body.

G Ensure correct combination of actuator

and valve body of control valves with a

reduced valve seat.

G Compare the product label of the

actuator with the valve body marking.

Rxxxx

Rxxxx

Valve body marking

2/2-way body

Valve body marking

Angle body

Product label of

actuator

Valve body marking

RAxxx R002

RBxxx R004

RCxxx R006

RDxxx R008

RExxx R010

RFxxx R012

RGxxx R015

RHxxx R020

RJxxx R025

RKxxx R032

RMxxx R040

1. Move actuator A to the open position.

2. Actuator rotatable 360°. Position of the

control medium connectors is optional.

3. Lubricate thread of the union nut a with a

suitable lubricant.

4. Actuator sizes 0, 0K, 1, 1K, 2, 2K, 3, 3L, 4,

4L: Place actuator A on valve body 1

approx. 90° anticlockwise to the desired

end position of the control medium

connectors and screw it down hand tight

using union nut a.

5. Actuator size B: place actuator A on valve

body 1 and tighten with a pin wrench

(pin size 3 mm). The control medium

connector is rotatable 360°, even after

the actuator is fi xed.

Actuator sizes 0, 0K, 1, 1K, 2, 2K, 3, 3L,

4, 4L: Tightening the union nut a with

an open-end wrench (torques see table

below) rotates the actuator clockwise

approx. 90° to the desired position.

6. Move actuator A to the closed position,

check function and tightness of

completely assembled valve.

Actuators B, 0, 1, 2, 3 and 4

Nominal size Torques [Nm]

DN 6 35

DN 8 35

DN 10 35

DN 15 35

DN 10 90

DN 15 90

DN 20 100

DN 25 120

DN 32 120

DN 40 150

DN 50 200

DN 65 260

DN 80 280

Loading...

Loading...