Gaseous Fuel Systems

Installation Guidelines for Spark-Ignited Stationary Emergency Generators 25

To size an LP tank for a desired run time the following information is required:

• The maximum vapor consumption of the generator (in BTU/hr) at 100% load. The specification sheet for the gen-

erator will list the fuel consumption rate, usually in cubic feet per hour. To convert CFH to BTU/hr, multiply by

2520.

• The fuel consumption rate in gallons per hour with the generator at 100% load. To convert CFH (propane vapor)

to GPH, divide by 36.38. To convert BTU/hr to GPH, divide by 91502.

• The desired run time.

• The minimum operating temperature expected.

The most important thing to consider when sizing LP tanks for vapor withdrawal is the vaporization rate of the tank at

the minimum temperature expected, and at the minimum fuel level the tank will be allowed to reach. The vaporization

rates shown in Table 5-4 are based on the tank at 20% of its fill capacity.

1. Multiply the gallons per hour fuel consumption rate of the generator at 100% load by the longest run time

expected/desired.

2. Determine the fuel consumption in BTU/hr with the generator at 100% load.

3. Determine the lowest expected operating temperature.

4. See Table 5-4. Using both the Minimum Operating Temperature and the Tank Vaporization Capacity columns,

find the BTU/hr vaporization rate of the generator at 100% load that corresponds to the lowest expected operat-

ing temperature.

5.

Look back at column 2, note the Available Tank Capacity. If it is greater than the total run time fuel consumption

refer back to column 1- this is the correct size tank required. If it is less than the total run time fuel consumption,

then go to the next larger tank size. Recheck the lowest operating temperature and the tank vaporization capacity.

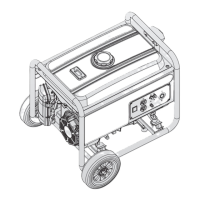

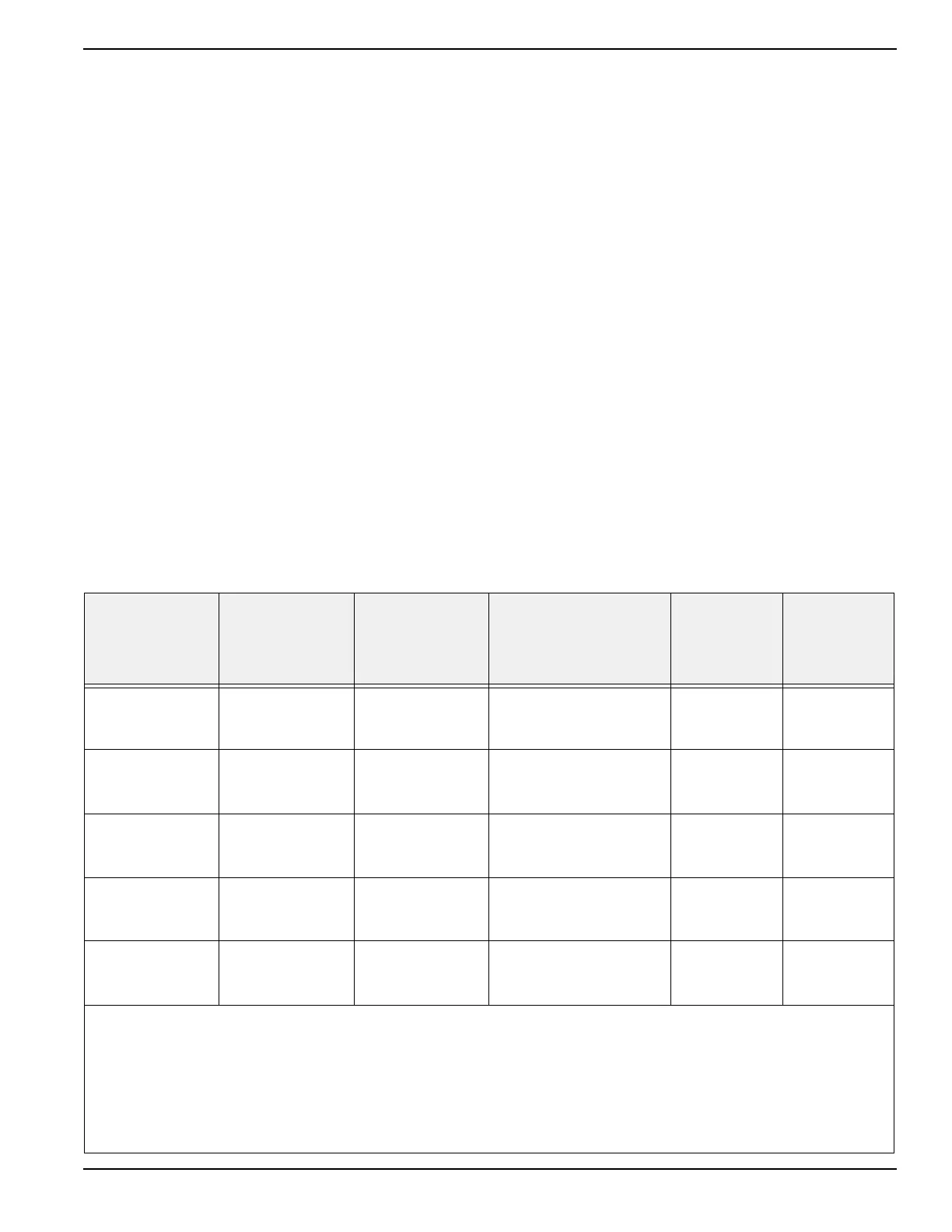

Table 5-4. Vaporization Rates

Tank Capacity

Total (gal)

See Note 1

Available Tank

Capacity (gal)

See Note 2

Minimum

Operating

Temperature

(º F)

Tank Vaporization

Capacity (BTU/hr)

See Note 3

Length

(In.)

Diameter

(In.)

250 150

40

20

0

507,600

338,400

169,200

94 30

325 195

40

20

0

642,600

428,400

214,200

119 30

500 300

40

20

0

792,540

528,360

264,180

119 37

850 510

40

20

0

1,217,700

811,800

405,900

165 41

1000 600

40

20

0

1,416,960

944,640

472,620

192 41

Note 1: The minimum LP tank size is 250 gallons, unless unit calculations dictate use of a larger tank. Vertical tanks, which are

measured in pounds, will not usually meet the minimum tank size (250 Gallons x 4.20 Pounds = approximately a 1050

pound vertical tank minimum).

Note 2: The available tank capacity is approximately 60% of the total fill capacity. This is based on a maximum fill level of 80%

and a minimum operating level of 20% (80%-20% = 60%).

Note 3: The vaporization capacity shown is based on a tank level of 20%. This represents the smallest allowable wetted surface

area of the liquid in the tank. As the liquid level goes up, the wetted surface area and the vaporization rate increases.

Loading...

Loading...