X350 3D-Printer Quick Start Guide

Seite: 14/29

Stand: 2016/03/24 13:55

© German RepRap GmbH 14/29

If the content of the SD-card is not displayed after inserting it into the card reader, the file may also

be selected through the menu on the LCD display: Press the button →”SD-Card” → “Print file” → Select

file.

Removing the printed object

In order to remove a printed object upon completion, take the following steps:

Let the printing bed cool down

●

Carefully check if the piece can be removed easily by hand

●

If it sticks too strongly, use the included spatula to carefully loosen the object from the printing bed

●

Cleaning the printing head (extruder)

After some time the nozzle and the heating block of the Hot-End may get dirty. In order to clean it,

take the following steps:

Put the printing head into an easily reachable and comfortable position

●

Heat up the Hot-End to the temperature of the respective used material

●

Clean the nozzle and the heating block from below with the included brass brush

●

Material selection

The temperatures listed here are based on our printers and

should be treated as a recommendation only. Please tweak

them to your own needs as required.

3D printers need materials to create object from like “common” printers. Depending on the printers

technology you are able to use different types of materials.

Thermoplastic, also known as a thermosoftening plastic, is a polymer that turns to a liquid when

heated and freezes to a very glassy state when cooled sufficiently. Thermoplastic polymers differ

from thermosetting polymers (Bakelite) in that they can be remelted and remoulded. Many

thermoplastic materials are addition polymers; e.g., vinyl chain-growth polymers such as polyethylene

and polypropylene.

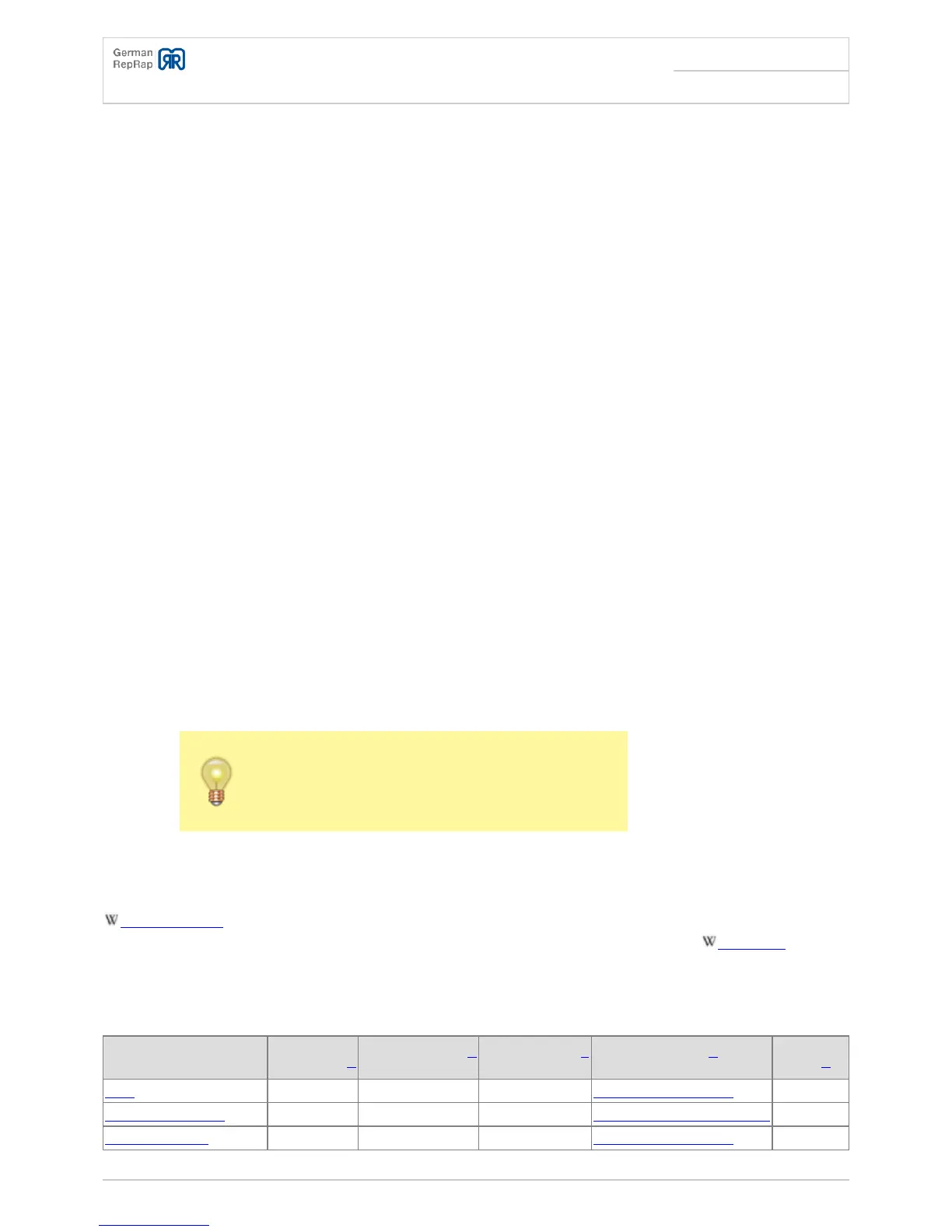

Filament type

Melting

point (°C)

1)

Extruder (°C)

2)

Printbed (°C)

3)

Surface

4)

Stable

(°C)

5)

ABS 220° ~230° - 255° ~ 110° - 115° Carbon/PET/Kapton ~ 140°

PLA - Polyactose 200° ~180° - 220° ~ 55° - 65° Carbon/PET/Kapton/Glas ~ 60°

PS - Polystyrol 210° ~190° - 220° ~ 80° - 100° Carbon/PET/Kapton –

Loading...

Loading...