85

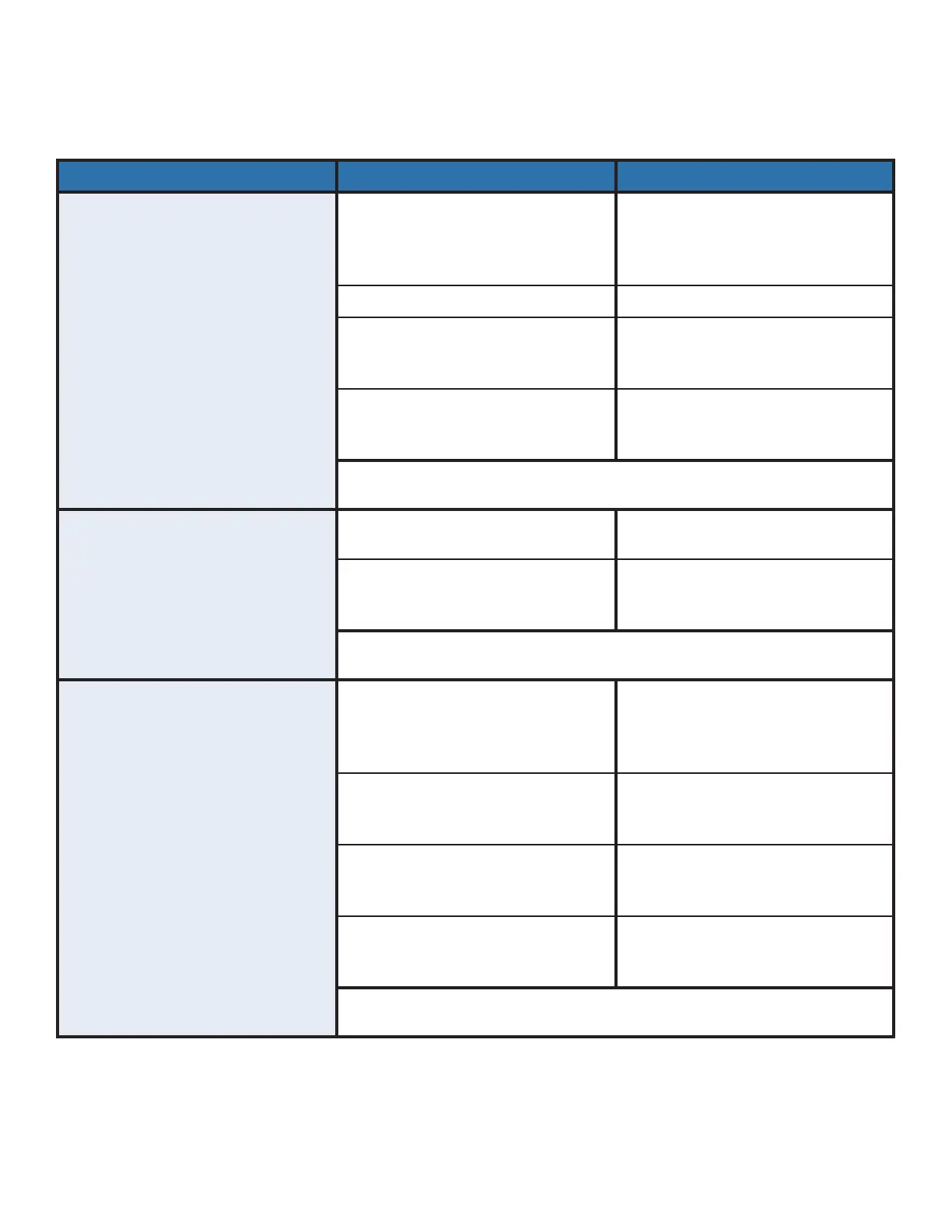

Issue Cause(s) Solution

Thread is breaking. Bobbin inserted incorrectly Check bobbin is the correct

direction in the case and

inserted rmly (clicked) into the

machine (page 31).

Debris on tension discs Clean the machine (page 53).

Burred bobbin Check bobbin for sharp edges.

Contact your dealer to replace if

needed.

Needle plate is rubbing needle Check that needle plate is

centered and does not hit

needle (page 64).

If problem persists, please contact a Grace Company support

technician. Call (800) 264-0644.

Machine is running loud. Machine and/or hook assembly

needs oiling

Oil the machine and hook

assembly (page 53).

Bobbin winder is on Check that bobbin cam is in

“O” position (away from

Bobbin stand).

If problem persists, please contact a Grace Company support

technician. Call (800) 264-0644.

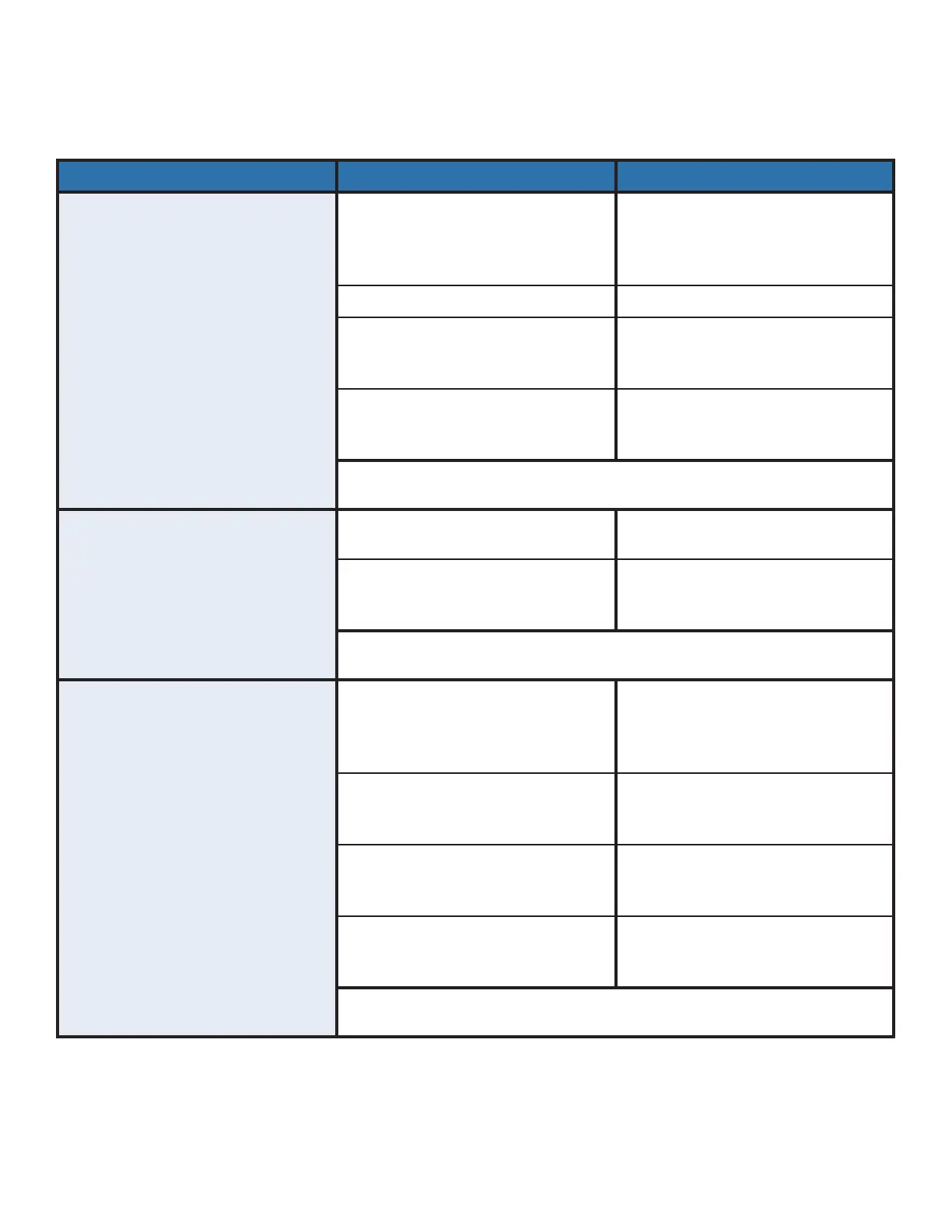

Thread is bunching up in

hook assembly (bobbin case

area).

Bobbin wound or threaded

incorrectly

Check that the bobbin was

threaded correctly and inserted

the correct direction in the case

(page 31.

Machine improperly threaded Check that all tensioners and

guides were threaded (page

34).

Incorrect thread tension Adjust top thread tension (page

49). Adjust bottom thread

tension (page 31).

Bobbin case has damaged or

missing spring

Check inside bobbin case to see

spring. Contact your dealer to

replace if needed.

If problem persists, please contact a Grace Company support

technician. Call (800) 264-0644.

Appendix

Loading...

Loading...