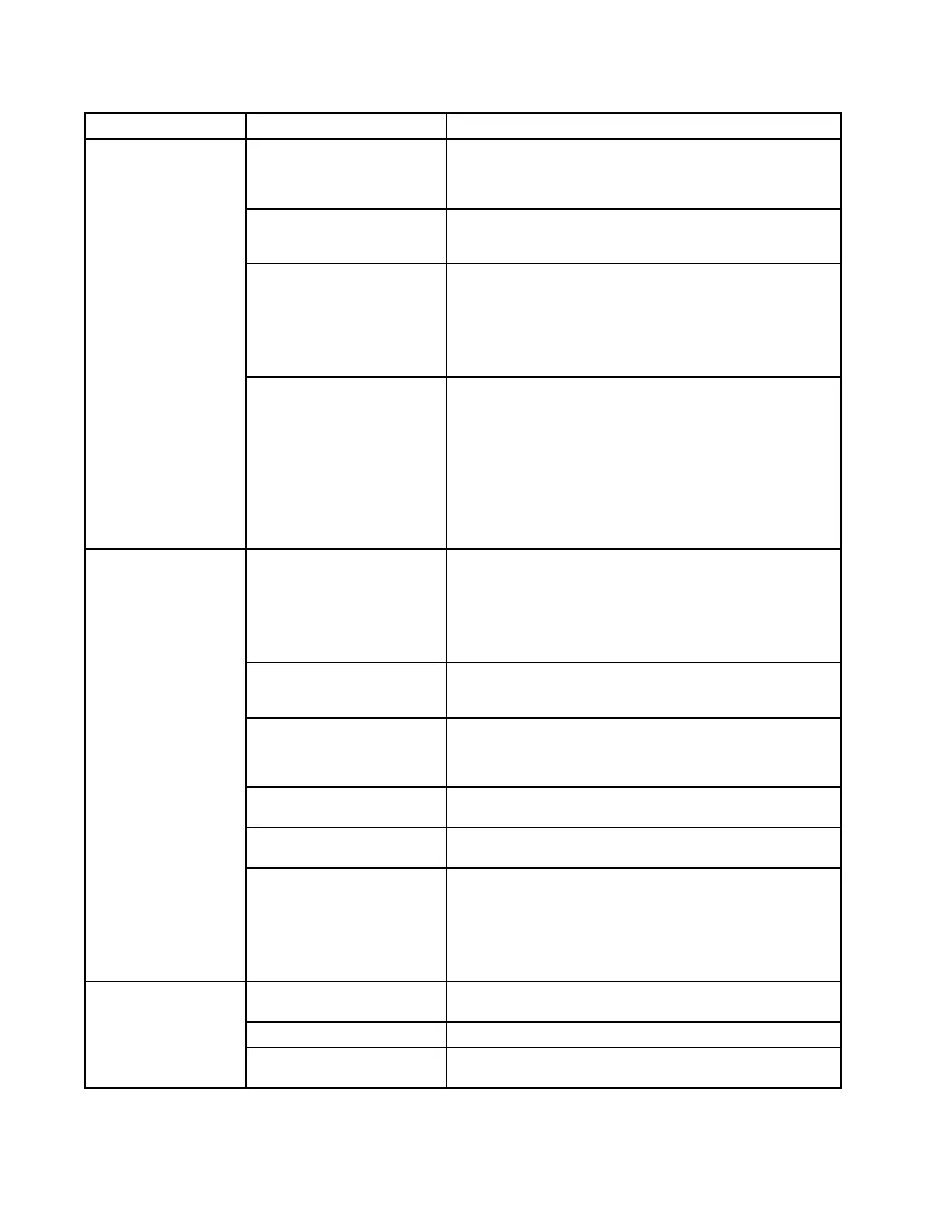

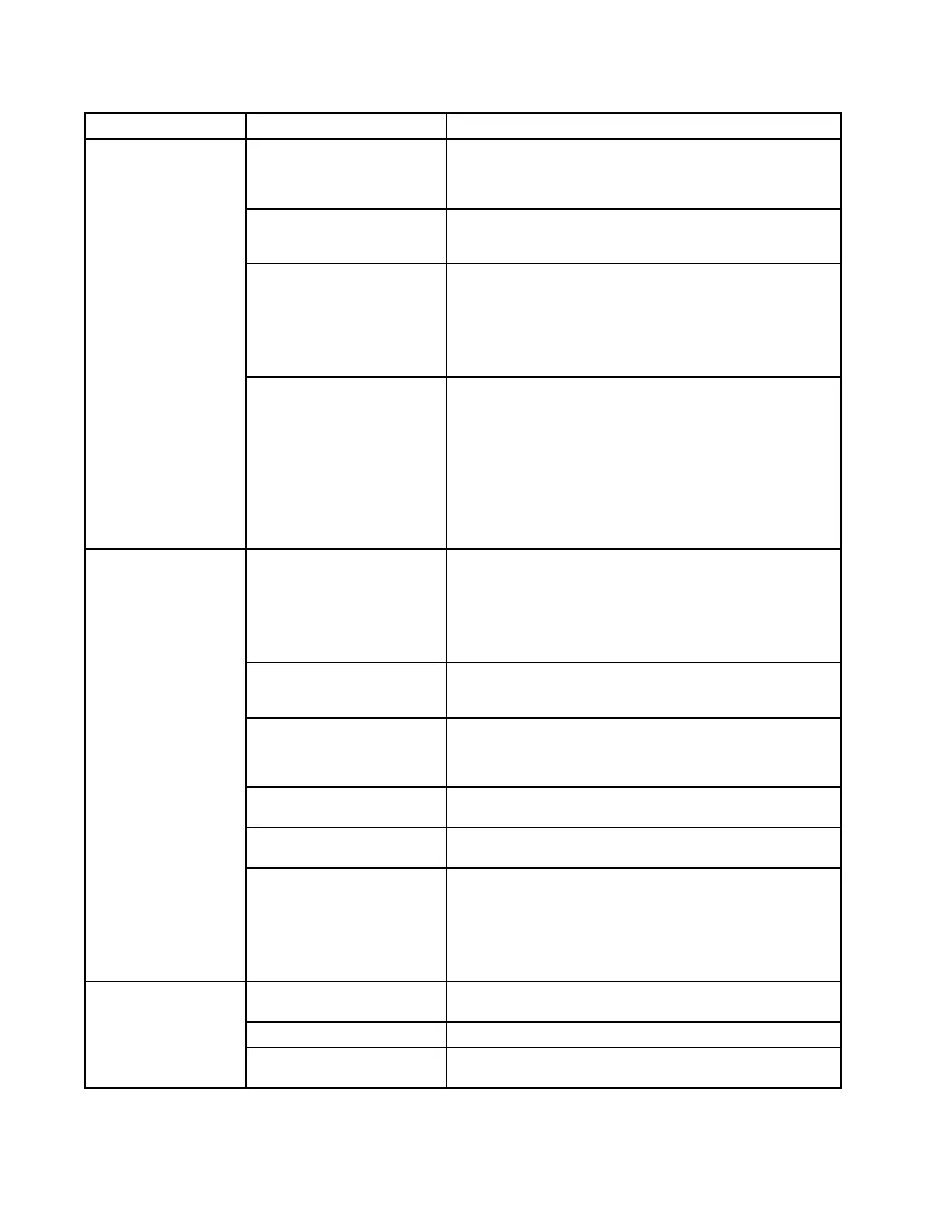

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Thesupplyairpressureis

uctuating

Makesurethecompressormeetsminimumow

requirementsandisoperatingproperly.See

TechnicalSpecications,page67formoreinformationon

owrequirements.

Themainairregulatoris

malfunctioningorisstuck

open.

Disassemblethemainairregulatorandcheckfor

obstructions.Replaceorrepairpartsasnecessary(see

EnclosureBoxParts,page50).

Theelectricblastcontrol

circuitismalfunctioning.

Inspectthehosecablefordamagedorshortedpartially

openwiring.Checkthe3Afuseandreplaceifnecessary.

Checkforloosewireconnectionsontherecessedplugson

thecontrolbox(P)andallexternalcables.Checkcontinuity

throughtheelectricblastcontrolswitch(B)(theswitchis

normallyopen).Ifallaboveitemsarefunctional,replacethe

4-waysolenoidvalve.

Whiletheblastcontrol

switch(B)isengaged,

theblastairowis

uctuating.

Thepneumaticblastcontrol

circuitismalfunctioning.

Actuatetheblastcontrolswitch(B)andcheckforproperspool

valveactuationinthe4-wayvalve.Ifnoactuationoccurs,

checktheblastcontrolswitchbydisconnectingtheyellow

tubeattheenclosuremalequickdisconnectandengagethe

controlswitch.Ifonlyalittleaircomesfromthetting,check

thetwin-linehosefordamageorcrimpingandcheckthe

pneumaticblastcontrollter.Ifthetwin-lineandlterare

clean,replacethepneumaticblastcontrolswitch.Iftheswitch

isfunctioning,makesuretheyellowtubinginsidethecontrol

boxisproperlyconnectedandclearanyobstructions.Ifall

aboveitemsarefunctional,replacethe4-waysolenoidvalve.

Theairsupplyisinadequate.

Makesuretheaircompressoriscapableofsupplying

theminimumairowrequirementforyoursystem(see

TechnicalSpecications,page67).Makesuretheairinlet

pressuregaugereads100-175psi(6.8–12bar,0.68–1.2

MPa).Ifthegaugedoesnotread100–175psi,checktheair

compressorforpropersetup.Makesuretheairinletlters

arecleanandreplaceifnecessary.

Theblasthosewasnot

properlycleanedoutafter

previoususe.

SeeShuttingDown,page21.

Theabrasivemeteringvalve

settingistoohighfortheblast

pressureand/orabrasive

type.

SeeSettingtheAbrasiveMeteringValve,page17.

Thepotdoesnothavea

sufcientamountofabrasive.

Rellthepotwithabrasive(see

RellingthePotwithAbrasive,page21).

Thereisanobstructioninthe

nozzle

Removethenozzleandinspectforblockage,buildup,or

damage.Replaceifnecessary.

Theblastspray

patternissputtering

orirregular.

Thereisanobstructioninside

thepotorinsidetheabrasive

hosebetweenthepotandthe

enclosure.

PerformDrainingthePot,page22,followedby

PressureReliefProcedure,page10.Withtheabrasive

hosedisconnected,inspecttheinteriorofthepinchhose

forobstructionsordebrisandreplaceifnecessary(see

ReplacingthePinchHose,page32).Removethetri-clamp

fromthebottomofpot.Inspectthebottomofthepotand

abrasivehoseforobstructionsordebris.

Thereisnotenoughwaterin

abrasivemixture.

SeeUsingtheWaterDoseMeter,page24(anupgradekitis

availablefornon-Elitemodels).

Theblastpressuretoohigh.Decreasetheblastpressureandre-evaluatethedustlevels.

Toomuchdustoccurs

duringblasting.

Theabrasiveistooneforthe

application.

Tryacoarserorharderabrasiveifpossible.

28 3A3489E

Loading...

Loading...