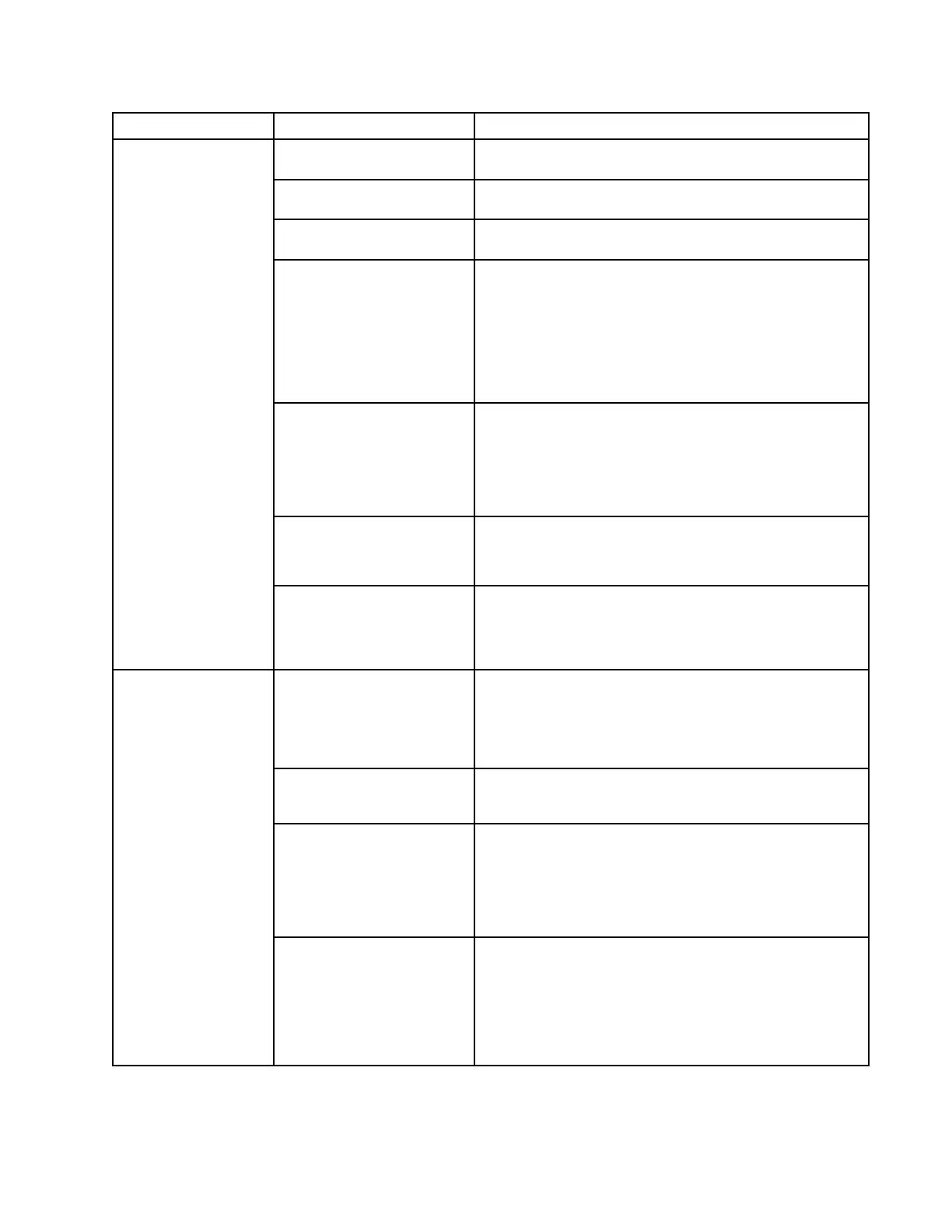

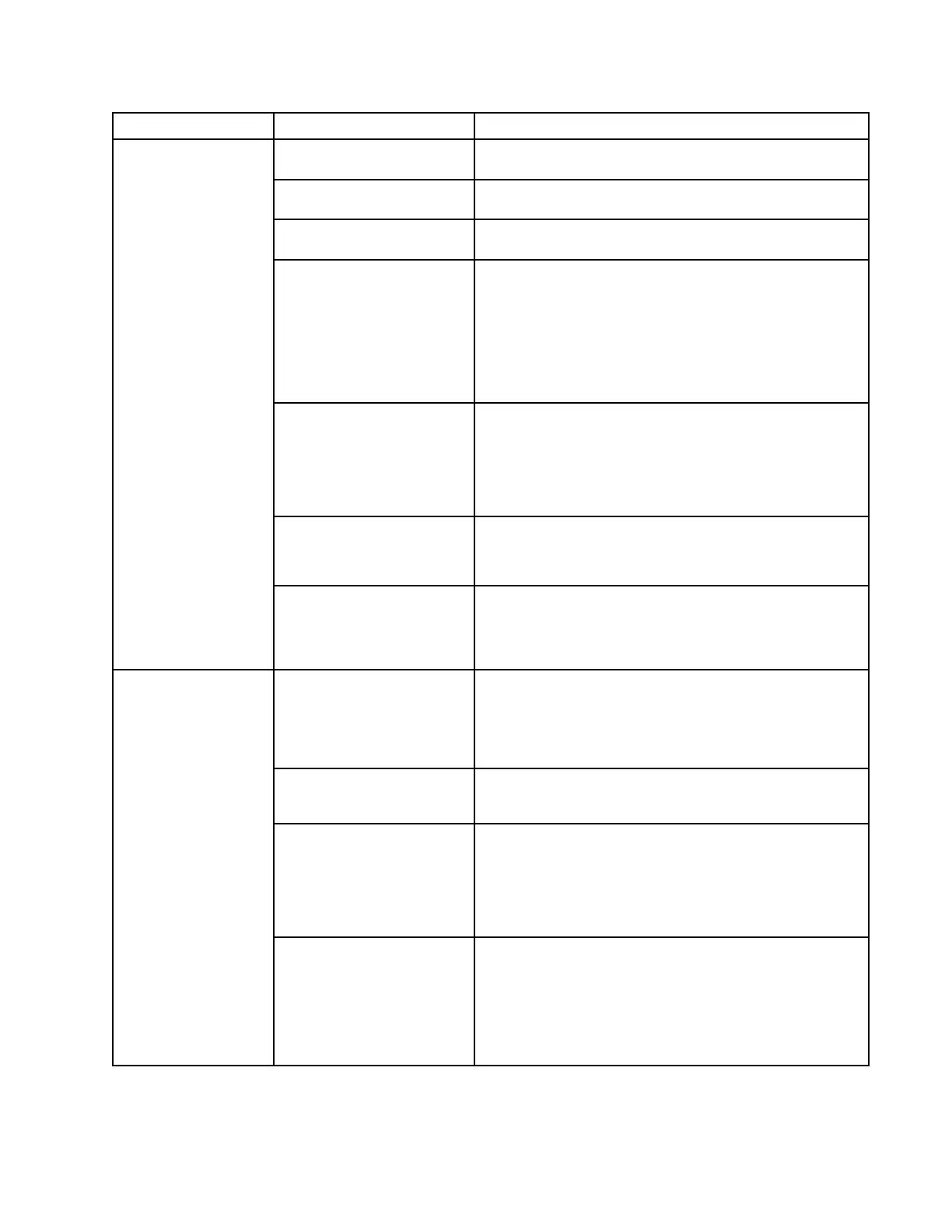

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Theabrasiveballvalveis

closed.

SeeSettingUptheEquipment,page14.

Theabrasivemeteringvalve

isnotproperlyset.

SeeSettingUptheEquipment,page14.

Thepotdoesnothavea

sufcientamountofabrasive.

SeeRellingthePotwithAbrasive,page21.

Thepinchvalvedoesnot

open.

Engagetheblastcontrolswitch(B)andcheckforactuation

ofthepinchvalve.Ifthereisnoactuation,disconnectthe

orangetubingatthepinchvalve.Ifthepinchvalveopensand

sourceairiscomingfromtheorangetubing,conrmthatthe

tubingiscorrectlyrouted.Ifthepinchvalvedoesnotopen,

replaceit.Ifthepinchvalveopensandthereisnosourceair

comingfromthetubing,inspectthemufersonthe4-way

valvefordebris.Ifdebrisisnotpresent,cleanorreplacethe

4-wayvalve.

Thereisanobstructioninside

thepotorinsidetheabrasive

hosebetweenthepotandthe

enclosure.

FollowDrainingthePot,page22,followedbythe

PressureReliefProcedure,page10.Withtheabrasive

hosedisconnected,inspecttheinteriorofthepinchhose

forobstructionsordebrisandreplaceifnecessary(see

ReplacingthePinchHose,page32).Removethetri-clamp

fromthebottomofthepot.Inspectthebottomofthepotand

theabrasivehoseforobstructionsordebris.

Thepotpressureistoolow.Withtheblastcontroldisengaged,allowthepottopressurize

andwaitforthepumptostall.Ifthepotpressuregaugedoes

notreach185psi(12.75bar,1.275MPa),seethe“Unableto

llorpressurizethepotwithwater”problemlistedinthistable.

WhileinBLASTmode,

withtheblastcontrol

switch(B)engaged,

airisowingfromthe

nozzlebutlittleorno

abrasiveisowingfrom

thenozzle.

Theblastpressureistoohigh.

Iftheblastpressuregaugereads160psi(11.03bar,1.10

MPa)orgreater,itmaynotbepossibletoachievegreater

than15CPMontheMediaTrak.Thisismorecommonwith

nemeshabrasiveusage.Decreasetheblastpressureto

100psi(6.9bar,0.69MPa)toseeifCPMcanbeincreased.

Theairsupplyisinadequate.

Makesuretheaircompressoriscapableofsupplying

theminimumairowrequirementforyoursystem(see

TechnicalSpecications,page67).Makesuretheairinlet

pressuregaugereads100-175psi(6.8–12bar,0.68–1.2

MPa).Ifthegaugedoesnotread100–175psi,checktheair

compressorforpropersetup.

Themainairregulatoris

malfunctioningorisstuck

open.

Disassemblethemainairregulatorandcheckfor

obstructions.Replaceorrepairpartsasnecessary(see

EnclosureBoxParts,page50).

Theelectricblastcontrol

circuitismalfunctioning.

Unplugthehosecableatthecontrolbox.Iftheblaststops,

inspectthehosecableforshortedwiring.Checkcontinuity

throughtheelectricblastcontrolswitch(B)(theswitchis

normallyopen).Checkforcontinuityacrossconnectorsof

therecessedplugsonthecontrolbox(thereshouldbeno

continuity).Ifallaboveitemsarefunctional,replacethe

4-Waysolenoidvalve.

Theblastcontrolswitch

(B)isnotengaged,but

blastingoccurs.

Thepneumaticblastcontrol

circuitismalfunctioning.

Engagetheemergencystop(Q).Ifblastingstops,checkthe

blastcontrolswitch(B)bydisconnectingtheyellowtubeat

theenclosuremalequickdisconnect.Thereshouldbeno

signalairunlessyouengagethecontrolswitch.Iftheswitch

isfunctioning,removetheexhaustmufersfromthe4-way

andcheckfordebris,cleanports,andreplacethemufers

ifnecessary.Ifallaboveitemsarefunctional,replacethe

4-waysolenoidvalve.

3A3489E

27

Loading...

Loading...