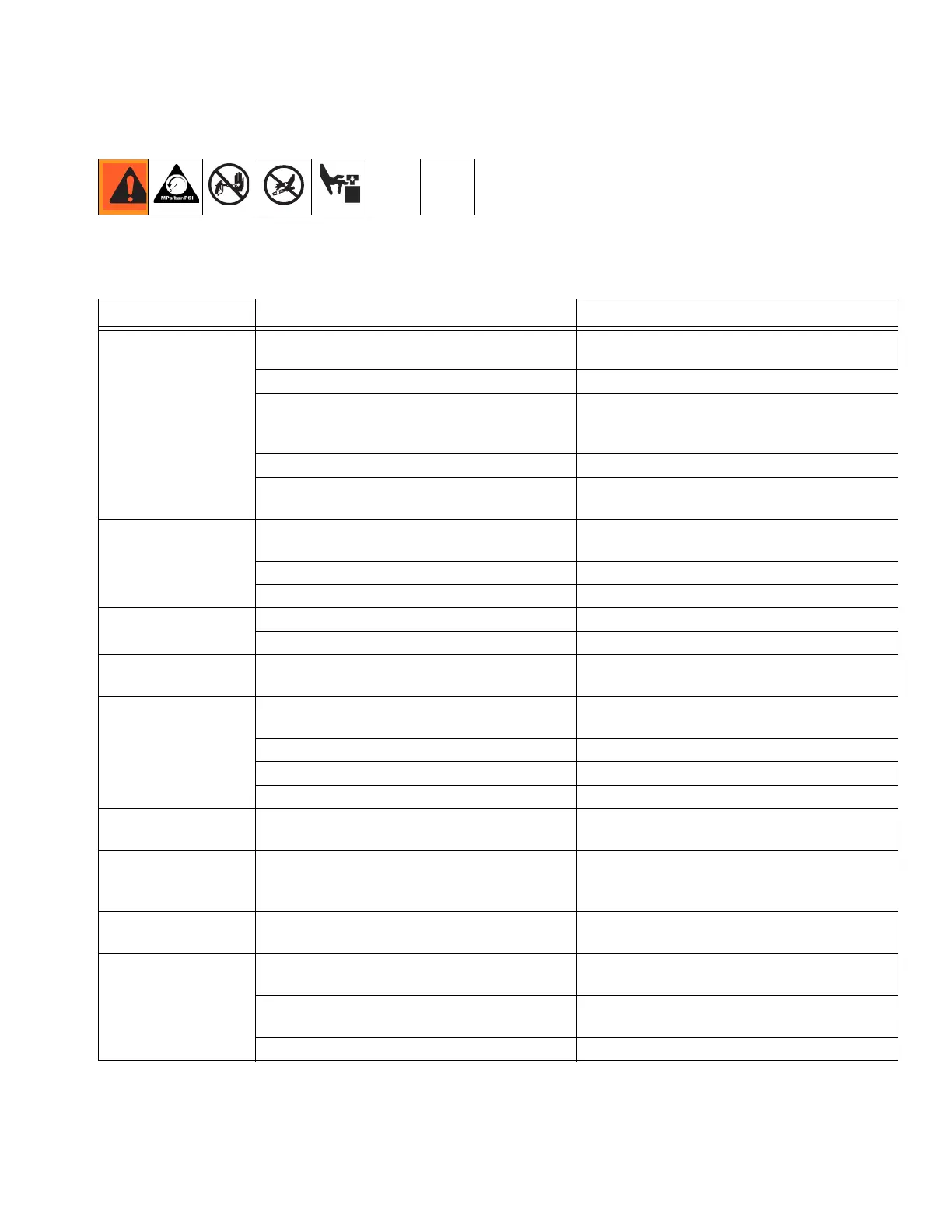

Troubleshooting

311164M 23

Troubleshooting

1. Follow Pressure Relief Procedure, page 13. 2. Check all possible causes and problems before dis-

assembling pump.

* To determine if fluid hose or gun is obstructed, follow Pressure Relief Procedure, page 13. Disconnect fluid

hose and place a container at pump fluid outlet to catch any fluid. Turn on air power just enough to start pump. If

pump starts, the obstruction is in fluid hose or gun.

Problem Cause Solution

Does not operate. Valve closed or clogged. Clear air line; increase air supply. Check that

valves are open.

Fluid hose or gun obstructed. Clean hose or gun.*

Dried fluid on displacement rod. Clean rod; always stop pump at bottom of

stroke; keep wet-cup filled with compatible

solvent.

Air motor parts dirty, worn, or damaged. Clean or repair air motor. See motor manual.

Runaway error on DataTrak tripped. See DataTrak Operation-Runaway, page

20.

Output low on both

strokes.

Air line restricted or air supply inadequate.

Valves closed or clogged.

Clear air line; increase air supply. Check that

valves are open.

Fluid hose/gun obstructed; hose ID too small. Clear hose or gun*; use hose with larger ID.

Air motor icing. Open De-Ice control; see page 11.

Output low on down

stroke.

Open or worn intake valve. Clear or service intake valve.

High viscosity fluid. Adjust intake spacers.

Output low on

upstroke.

Open or worn piston valve or packings. Clear piston valve; replace packings.

Erratic accelerated

speed.

Fluid supply exhausted, clogged suction. Refill supply and prime pump. Clean suction

tube.

High viscosity fluid. Reduce viscosity; adjust intake spacers.

Open or worn piston valve or packings. Clear piston valve; replace packings.

Open or worn intake valve. Clear or service intake valve.

Runs sluggishly. Possible icing. Stop pump. Open De-Ice control; see page

11.

Cycles or fails to hold

pressure at stall.

Worn check valves or seals. Service lower. See Xtreme Lower Removal,

page 24, and Xtreme Lowers manual

(311762).

Air bubbles in fluid. Loose suction line. Tighten. Use compatible liquid thread sealant

or PTFE tape on connections.

Poor finish or irregu-

lar spray pattern.

Incorrect fluid pressure at gun. See gun manual; read fluid manufacturer’s

recommendations.

Fluid is too thin or too thick. Adjust fluid viscosity; read fluid manufac-

turer’s recommendations.

Dirty, worn, or damaged spray gun. Service spray gun. See spray gun manual.

Loading...

Loading...