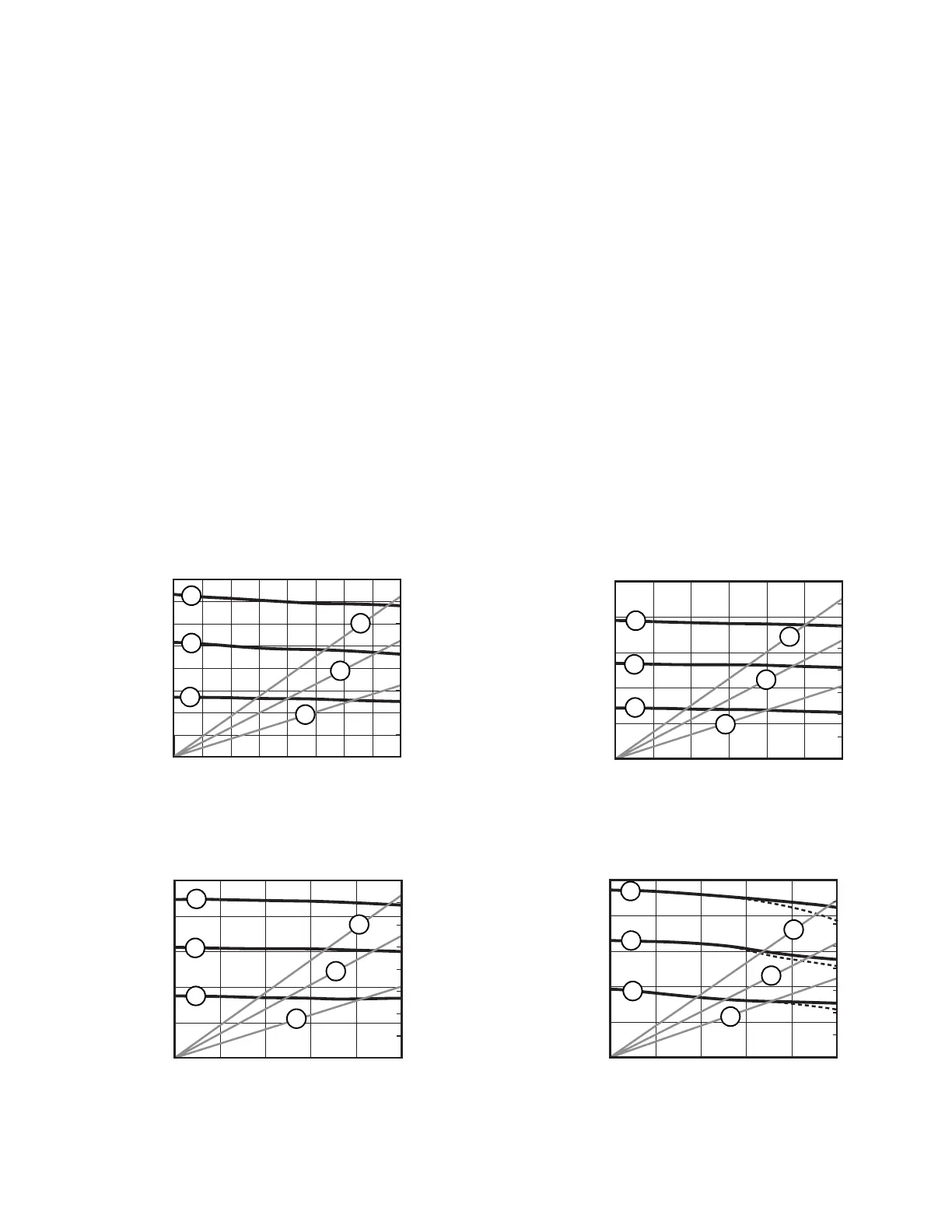

Pump Package Performance Charts

311164M 57

Pump Package Performance Charts

Calculate Fluid Outlet Pressure

To calculate fluid outlet pressure (psi/MPa/bar) at a spe-

cific fluid flow (gpm/lpm) and operating air pressure

(psi/MPa/bar), use the following instructions and pump

data charts.

1. Locate desired flow along bottom of chart.

2. Follow vertical line up to intersection with selected

fluid outlet pressure curve. Follow left to scale to

read fluid outlet pressure.

Calculate Pump Air Flow/Consumption

To calculate pump air flow/consumption (scfm or

m

3

/min) at a specific fluid flow (gpm/lpm) and air pres-

sure (psi/MPa/bar), use the following instructions and

pump data charts.

1. Locate desired flow along bottom of chart.

2. Follow vertical line up to intersection with selected

air flow/consumption curve. Follow right to scale to

read air flow/consumption.

16:1 Xtreme Pumps

Fluid Pressure in psig (MPa, bar)

Fluid Flow in gpm (lpm)

Air Flow in SCFM (m

3

/min)

800

1200

1600

400

02.0

3.01.0

(3.8)

(7.6)

(11.4)

4.0

(15.2)

21:1 Xtreme Pumps

Fluid Flow in gpm (lpm)

Fluid Pressure in psig (MPa, bar)

Air Flow in SCFM (m

3

/min)

0

2.0

3.0

1.0

(3.8)

(7.6)

(11.4)

(11.2, 112)

(8.4, 84)

(5.6, 56)

(2.8, 28)

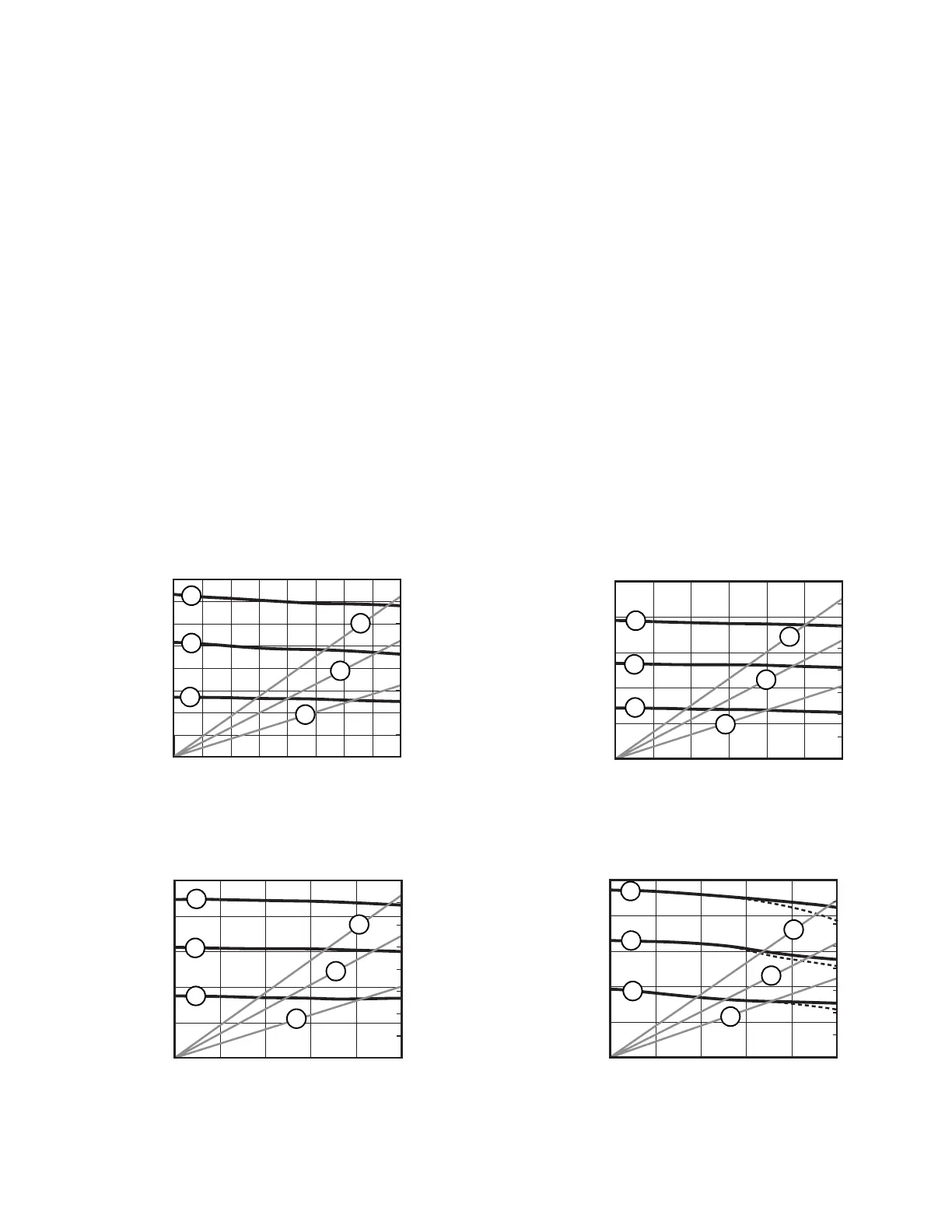

24:1 Xtreme Pumps

Fluid Pressure in psig (MPa, bar)

Air Flow in SCFM (m

3

/min)

Fluid Flow in gpm (lpm)

0

2.0

3.0

1.0

(3.8)

(7.6)

(11.4)

Fluid Pressure in psig (MPa, bar)

Fluid Flow in gpm (lpm)

0

5.03.0

Air Flow in SCFM (m

3

/min)

25:1 Xtreme Pumps

(11.4)

(19.0)

1.0

(3.8)

Key: Air Pressure

A 100 psi (0.7 MPa, 7 bar)

B 70 psi (0.5 MPa, 7.8 bar)

C 40 psi (0.3 MPa, 2.8 bar)

Dashed lines indicate low noise motors.

80

(2.2)

60

(1.7)

40

(1.1)

20

(0.6)

80

(2.2)

60

(1.7)

40

(1.1)

20

(0.6)

500

1500

2500

(17.5, 175)

(10.5, 105)

(3.5, 35)

500

1500

2500

(17.5, 175)

(10.5, 105)

(3.5, 35)

80

(2.2)

60

(1.7)

40

(1.1)

20

(0.6)

500

1500

2500

(17.5, 175)

(10.5, 105)

(3.5, 35)

160

(4.5)

120

(3.4)

80

(2.2)

40

(1.1)

A

C

A

A

B

B

C

C

A

A

A

A

A

B

B

B

B

B

C

C

C

C

C

B

Loading...

Loading...