Section 3: Installation InformationPage 14

3.10 Before you Commission

3.10.1 Flushing and Corrosion Protection

To avoid the danger of dirt and foreign matter entering the heat pump

the complete heating system should be thoroughly flushed out – both

before the heat pump is operated and then again after the system

has been heated and is still hot.

This is especially important where the heat pump is installed as a

replacement for a boiler on an existing system.

In this case the system should be first flushed hot, before the old

boiler is removed and replaced by the heat pump.

For optimum performance after installation, this heat pump and

the central heating system must be flushed in accordance with the

guidelines given in BS 7593:2006 ‘Treatment of water in domestic hot

water central heating systems’.

This must involve the use of a proprietary cleaner, such as Sentinel

X300 or X400, or Fernox Restorer.

After flushing, a suitable thermal fluid should be used (such as

Sentinel R600) specifically designed for use in air source heat pump

installations. This provides long term protection against corrosion

and scale as well as the risk of the freezing in the external section of

the heating system (i.e. the flexible hoses, condenser and circulating

pump within the heat pump casing) in the event of power failure

during winter months.

In order to avoid bacterial growth, due to the lower system operating

temperatures, a suitable Biocide (such as Sentinel R700) should also

be used in conjunction with the thermal fluid.

Both the thermal fluid and biocide should be added to the system

water when finally filling the heating system.

Alternatively, Fernox HP5C can be used (or HP15C for greater frost

protection).

This is a suitable thermal fluid that already contains a suitable

biocide.

Full instructions on the correct use of thermal fluids and biocides are

supplied with the products, but further information can be obtained

from either www.sentinel-solutions.net or www.fernox.com.

Failure to implement the above guidelines by fully flushing the system

and using a suitable thermal fluid and biocide corrosion inhibitor will

invalidate the heat pump product guarantee.

Grant Engineering (UK) Limited strongly recommends that a

Grant MagOne in-line magnetic filter/s (or equivalent*) is fitted

in the heating system pipework. This should be installed and

regularly serviced in accordance with the filter manufacturer’s

instructions.

* As measured by gauss. The MagOne magnetic filter has a gauss

measurement of 12000.

3.10.2 Anti-freeze function setting

This function is factory set to ON, i.e. DIP SW1 is set to ON (up

position).

With the frost protection function set to ON, it will operate as

described in Sections 8.4.1, 8.4.2 and 8.4.3.

Table 3-6: Antifreeze concentration

% Monoethylene glycol inhibitor 10% 20% 30% 40%

Freezing temperature* -4°C -9°C -15°C -23°C

Correction

factor

Capacity 0,996 0,991 0,983 0,974

Power absorbed 0,990 0,978 0,964 1,008

Pressure drop 1,003 1,010 1,020 1,033

* The temperature values are indicative. Always refer to the temperatures given for the specified product used.

For details of how to access the parameter settings, refer to Section 9.3.

This function is not required if ethylene glycol is used in the heating

system water to prevent freezing.

If a suitable concentration of ethylene glycol (heating system

antifreeze) is used in the system water. Refer to Table 3-6 for suitable

antifreeze concentrations or follow the manufacturer’s instructions

supplied with the antifreeze.

If not required, frost protection function can be disabled as follows:

• Remove the wiring cover at the right hand end of the heat pump.

Refer to Figure 6-1.

• Set DIP SW1 to OFF (down position). Refer to Figure 3-7.

• Replace the wiring cover and secure in place with the screws

provided.

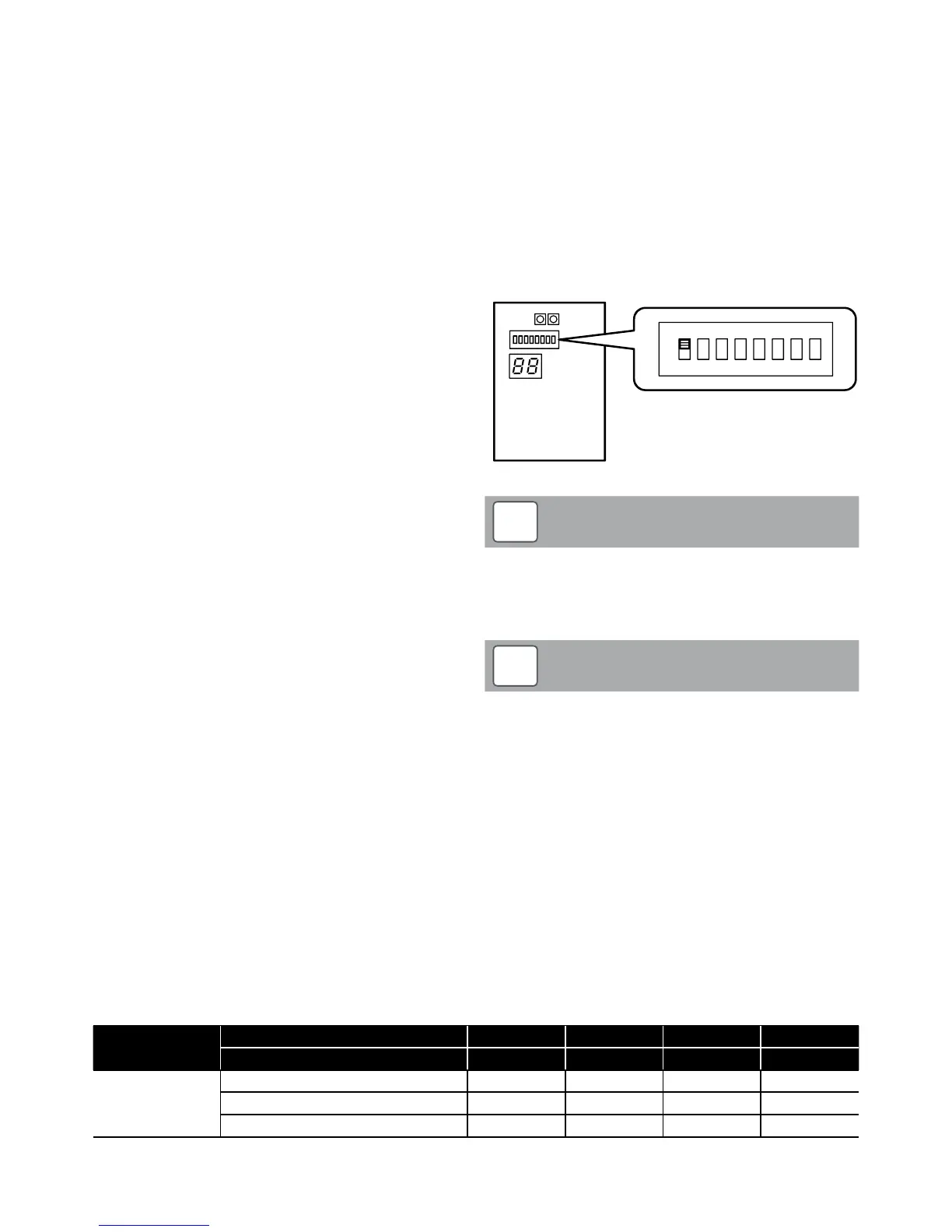

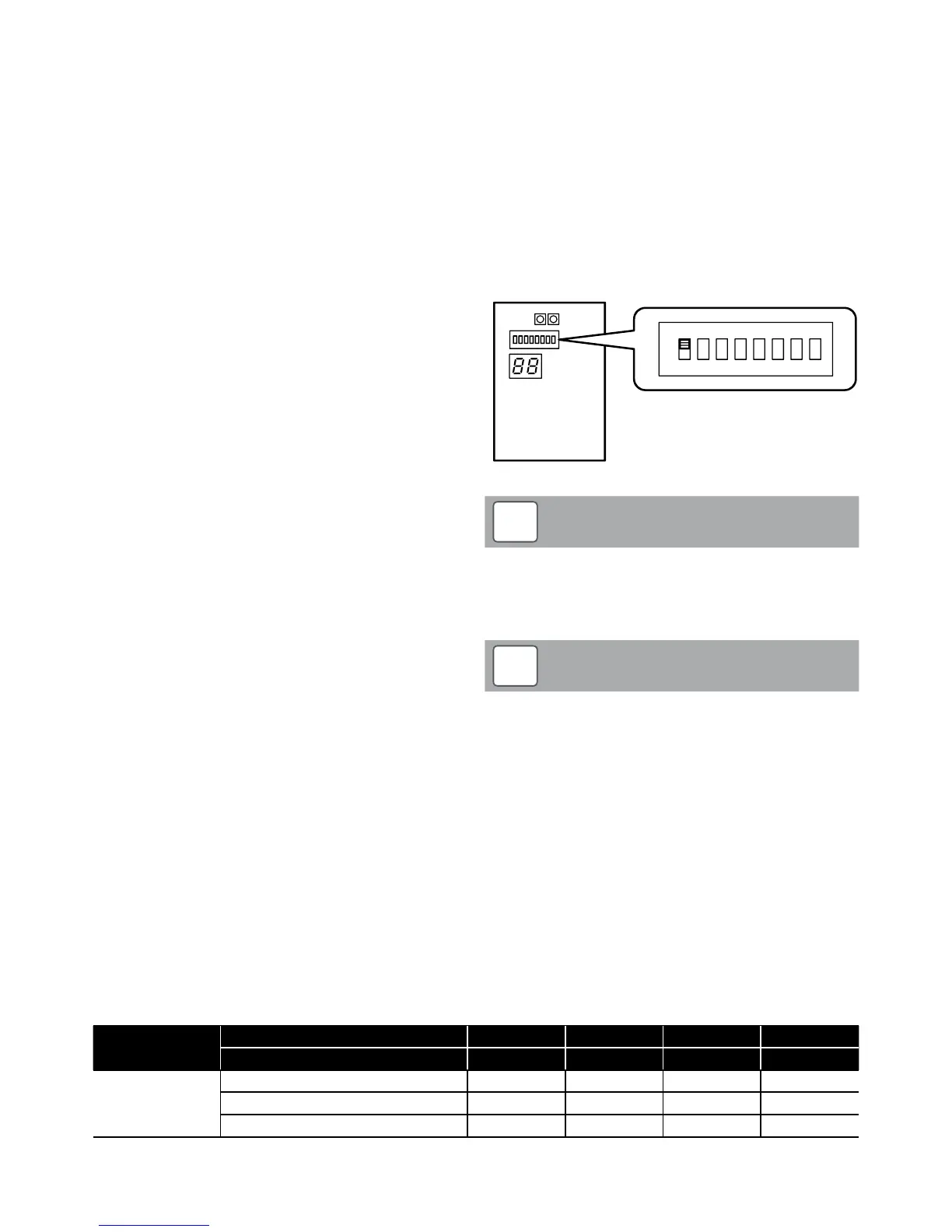

Terminal PCB

ON

1

OFF

DIP SW. position

2 3

4

5

6 7 8

Figure 3-7: Anti-freeze function setting

Dip switch positions:

Up: ON

Down: OFF

Refer to Sections 8.4.1, 8.4.2 and 8.4.3.

NOTE

!

Even with DIP SW1 set to OFF, to prevent the circulating pump

operating for frost protection it will also be necessary to reset

four of the factory set frost protection control parameters to

the ‘disabled’ setting. Refer to Table 3-8.

NOTE

!

To do this, use the remote controller as follows (refer to Section 9.1

page 46):

First access the Installer level:

1. Press and hold the ‘Menu’ (3) and the ‘-‘ and ‘+’ (6) buttons

together for 3 seconds to enter the installer level.

2. “InSt” parameter number “00 00” and parameter value “----“ will

be shown on the display. The first two digits of the parameter

number will be blinking.

Then, access the Service level:

1. Use the ‘Up’ and ‘Down’ (8) buttons to change these first two

digits to 99 and then press the ‘+’ button.

Loading...

Loading...