-30-

Model G0458Z (Mfd. Since 7/19)

Operation

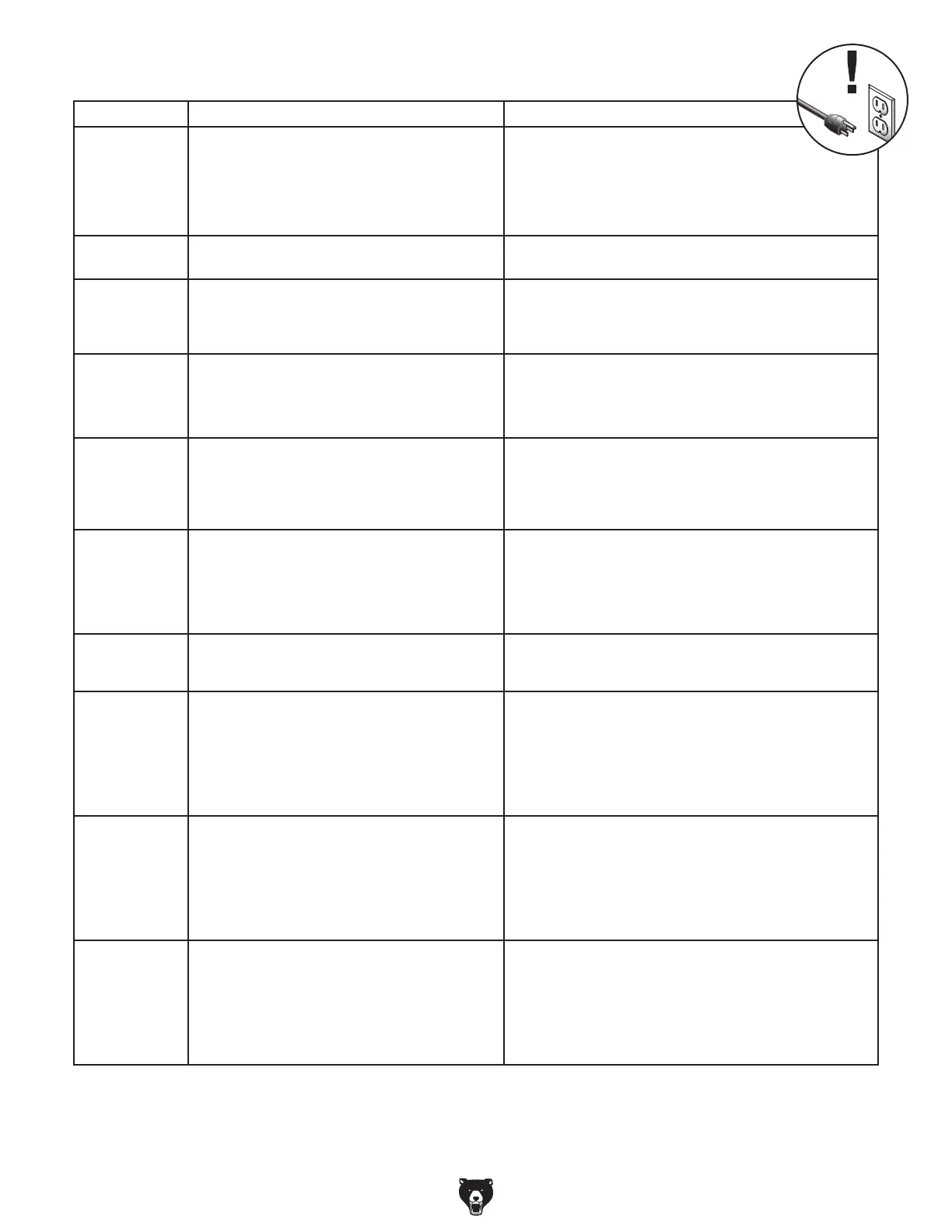

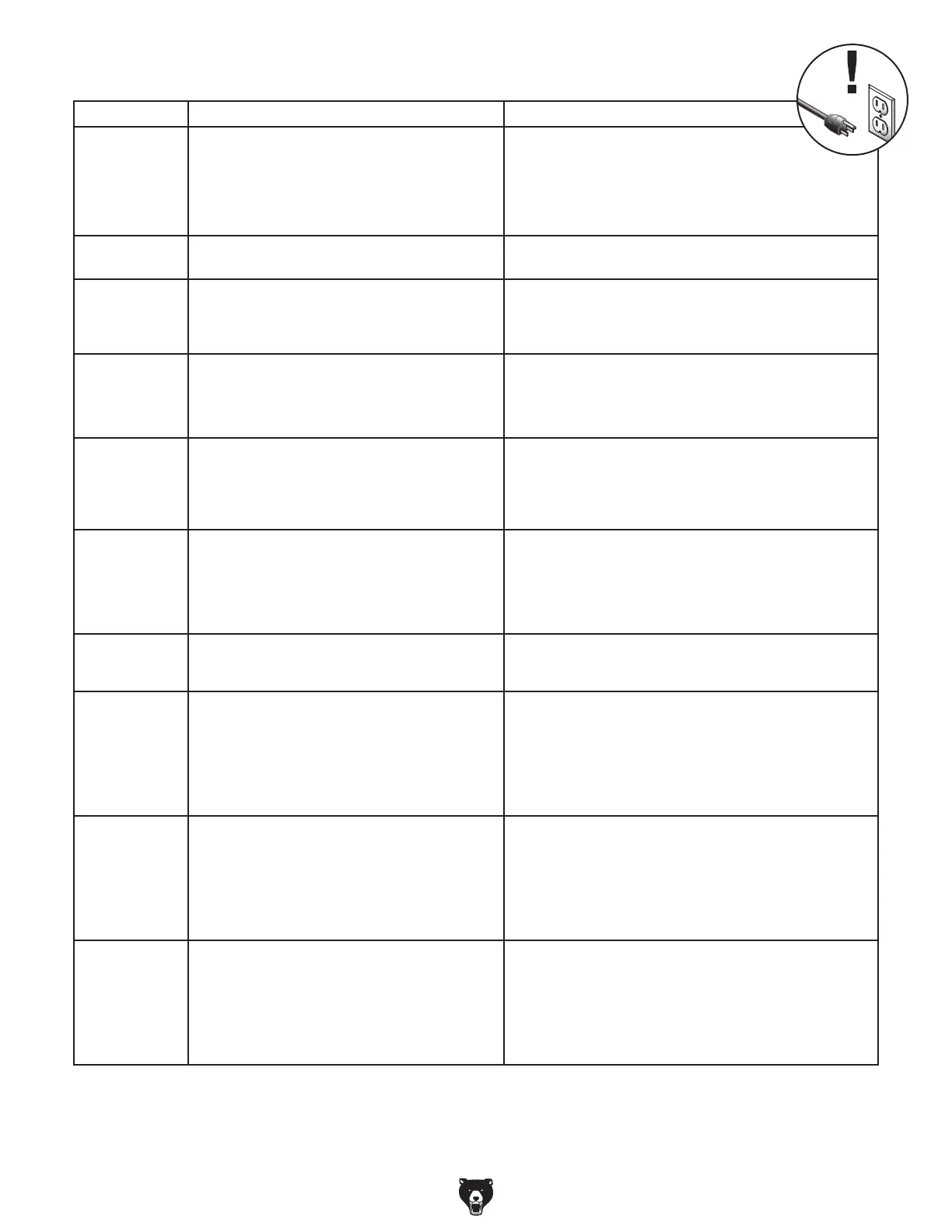

Symptom Possible Cause Possible Solution

Grinding,

screeching,

or rubbing

noise when

sanding drum is

powered up.

1. Drum bearings are worn and need

replacement.

1. Replace drum bearings.

Short V-belt

lifespan.

1. Pulleys not aligned correctly.

2. Improperly tensioned.

1. Align pulleys (Page 32).

2. Properly tension V-belt (Page 31).

Machine lacks

power; drum

stops turning

under load.

1. V-belt loose.

2. Too much pressure on sanding drum.

1. Tighten V-belt (Page 31).

2. Lower conveyor table (Page 38).

Conveyor

belt slips

under load.

1. Belt tension not properly adjusted.

2. Belt tracking not properly adjusted.

3. Conveyor belt worn.

4. Workpiece too heavy.

1. Properly adjust belt tension (Page 34).

2. Properly adjust belt tracking.

3. Replace conveyor belt.

4. Use lighter workpiece.

Conveyor belt

tracks to one

side or hits the

conveyor table

mounts.

1. Conveyor belt tracking is incorrect. 1. Track the conveyor belt so it runs straight (Page 33).

Excessive

snipe.

1. Lack of outfeed support.

2. Too much pressure from pressure rollers.

3. Too much pressure from the rear pressure

roller.

1. Set up an outfeed table or have someone catch the

workpiece as it comes out.

2. Raise pressure rollers (Page 38).

3. Raise rear pressure roller (Page 38).

Workpiece

kicks out of

sander.

1. Not enough pressure from pressure rollers. 1. Lower pressure roller (Page 38).

Sandpaper

comes off drum

or is loose.

1. Sandpaper not properly wrapped onto drum.

2. Sandpaper not cut to correct dimensions.

3. Torn or damaged sandpaper.

4. Sandpaper not tightened or fastened

correctly.

5. Sanding drum not parallel with table.

1. Re-install sandpaper (Page 23).

2. Use sandpaper cut to correct dimensions.

3. Replace sandpaper.

4. Re-install sandpaper.

5. Adjust sanding drum parallel to table.

Table elevation

controls are

stiff and hard to

adjust.

1. Table lift screws are dirty or loaded with

sawdust.

2. Chain idler sprocket cap screws have been

over tightened.

3. Elevation handwheel helical gear is dirty or

loaded with sawdust.

1. Clean and re-grease table lift screws (Page 28).

2. Adjust the cap screws on the idler sprocket so it can

spin freely.

3. Clean and re-grease the helical gear (Page 28).

Burn marks on

workpiece.

1. Using too fine of sanding grit for depth

of cut.

2. Sandpaper loaded with sawdust and gum

3. Feed rate too slow.

4. Sandpaper not properly wrapped onto drum.

5. Worn sandpaper.

1. Use coarser grit sandpaper or decrease depth of cut.

2. Clean/replace sandpaper.

3. Increase feed rate.

4. Re-install sandpaper.

5. Replace sandpaper.

Loading...

Loading...