Model G0458Z (Mfd. Since 7/19)

-31-

Proper tension is important for optimum power

transmission. However, too much tension may

cause premature bearing failure.

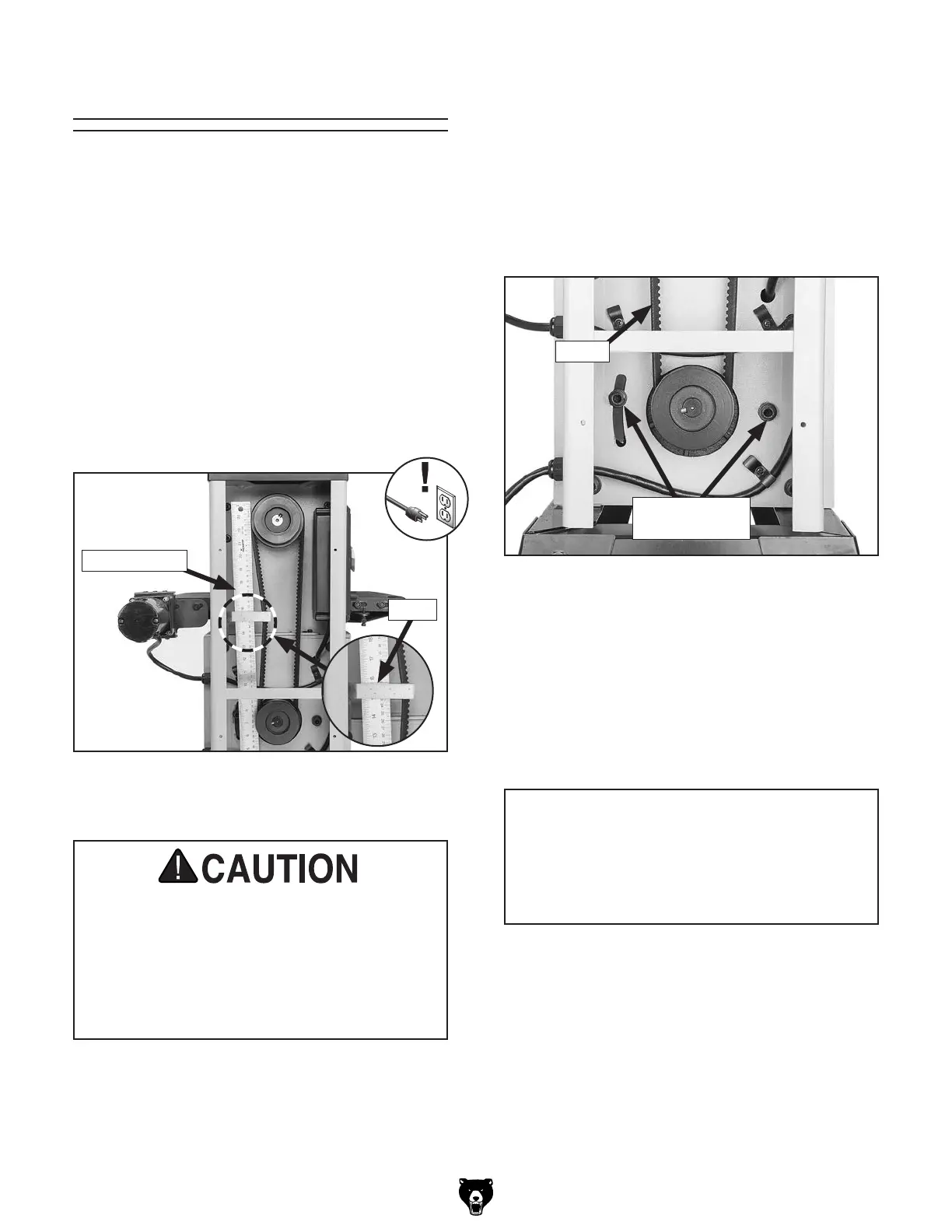

Correct V-belt tension is achieved when the

V-belts can be deflected

1

⁄2"–

3

⁄4" when pushed in

the middle with moderate pressure. See Figure 34

for an example of how to perform a V-belt deflec-

tion test with a straightedge and ruler.

Items Needed Qty

Hex Wrenches 4 & 8mm ............................. 1 Ea.

Phillips Head Screwdriver #2

.............................1

Straightedge

.......................................................1

Ruler

...................................................................1

Tensioning V-Belt

Figure 34. Checking V-belt tension with a

straightedge and a ruler (belt access panel

removed).

To adjust V-belt tension:

1. DISCONNECT MACHINE FROM POWER!

2.

Open belt access panel.

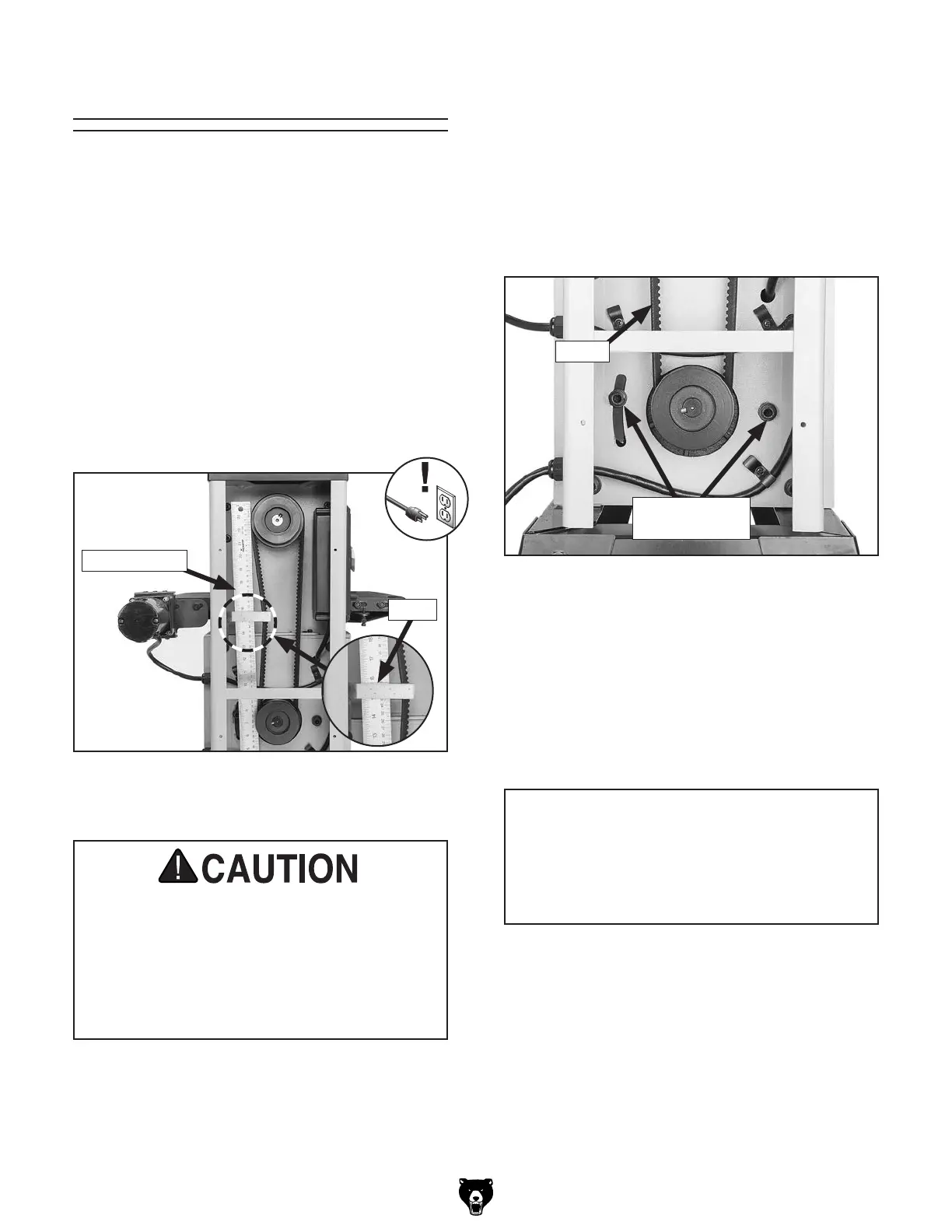

3. Check tension of V-belt, then adjust tension

by loosening motor mount cap screws shown

in Figure 35.

NOTICE

New V-belts will often stretch and loosen

after approximately 16 hours of use. Check

frequently after installation and re-tension

if necessary.

Figure 35. Feed belt V-belt tension.

V-Belt

Motor Mount

Cap Screws

4. Tension V-belt by pushing down on bottom

motor pulley with one hand, then tighten

motor mount cap screws and check belt ten-

sion.

5. Repeat Steps 3-4 as needed until V-belt is

correctly tensioned, then replace belt access

panel.

Always inspect V-belt for damage or dete-

rioration when adjusting for tension. Should

you find evidence of cracking, abrasion or

damage from wood chips or other foreign

materials, replace the belt immediately. Belt

breakage may lead to mechanical damage

or operator injury.

Straightedge

Ruler

Loading...

Loading...