Model G0458Z (Mfd. Since 7/19)

-39-

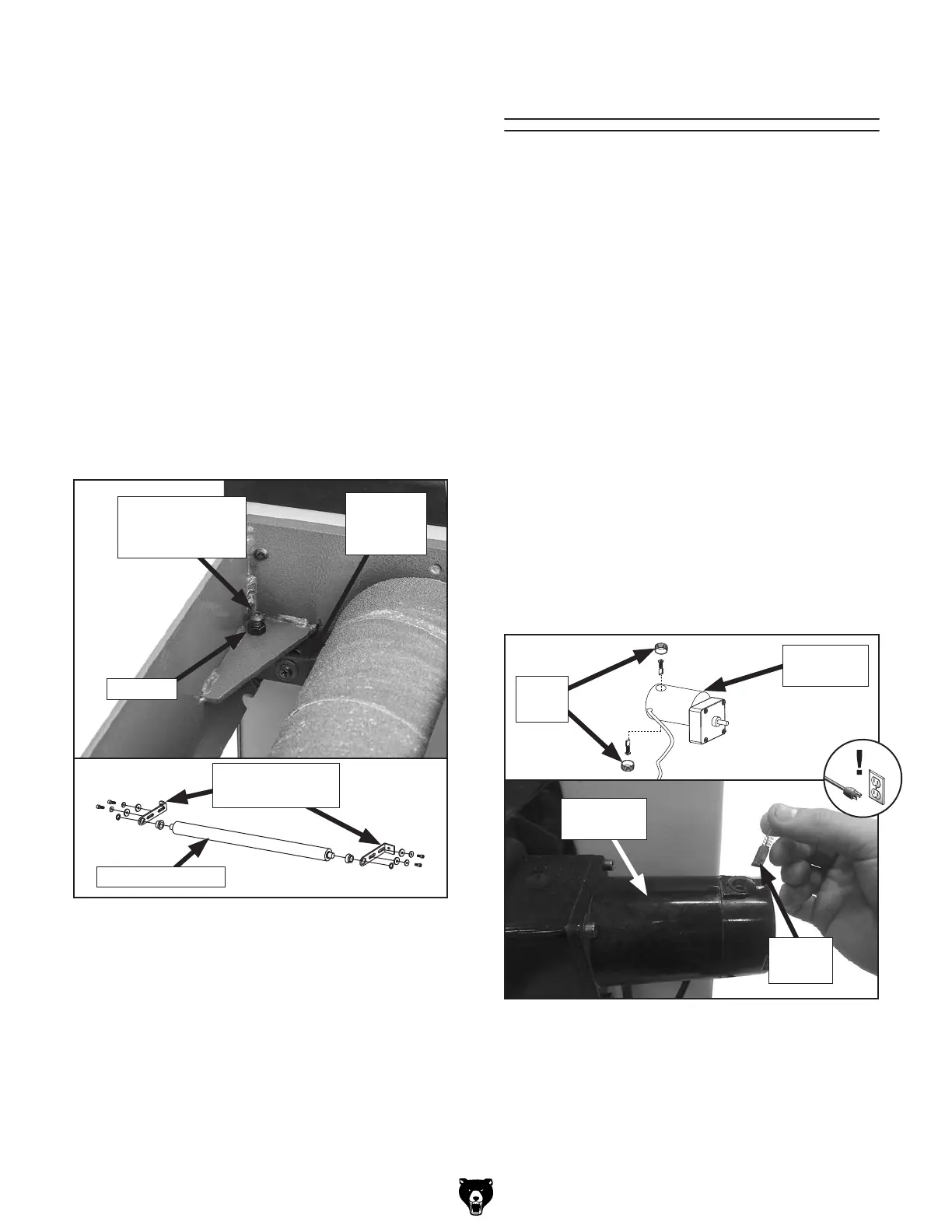

To adjust front pressure roller:

1. DISCONNECT MACHINE FROM POWER!

2.

Loosen hex nut securing adjustment cap

screws on both ends of rear pressure roller

shown in Figure 50.

3.

Rotate cap screw clockwise to raise pressure

roller, or counterclockwise loosen cap screw

to lower pressure roller.

Figure 50. Front pressure roller adjustments and

pressure roller overview.

Pressure Roller

Adjustment

Cap Screw

Hex Nut

Pressure

Roller

Pivot Bar

4. Adjust rear pressure roller until it is equal to,

or up to 0.004" (0.1mm) lower than height of

the drum.

3.

Rotate cap screw clockwise to raise the pres-

sure roller, or counterclockwise to lower pres-

sure roller.

4. Adjust rear pressure roller until it is equal to

or up to 0.004" (0.1mm) lower than height of

the drum.

Pressure Roller

Pivot Bars

Pressure Roller

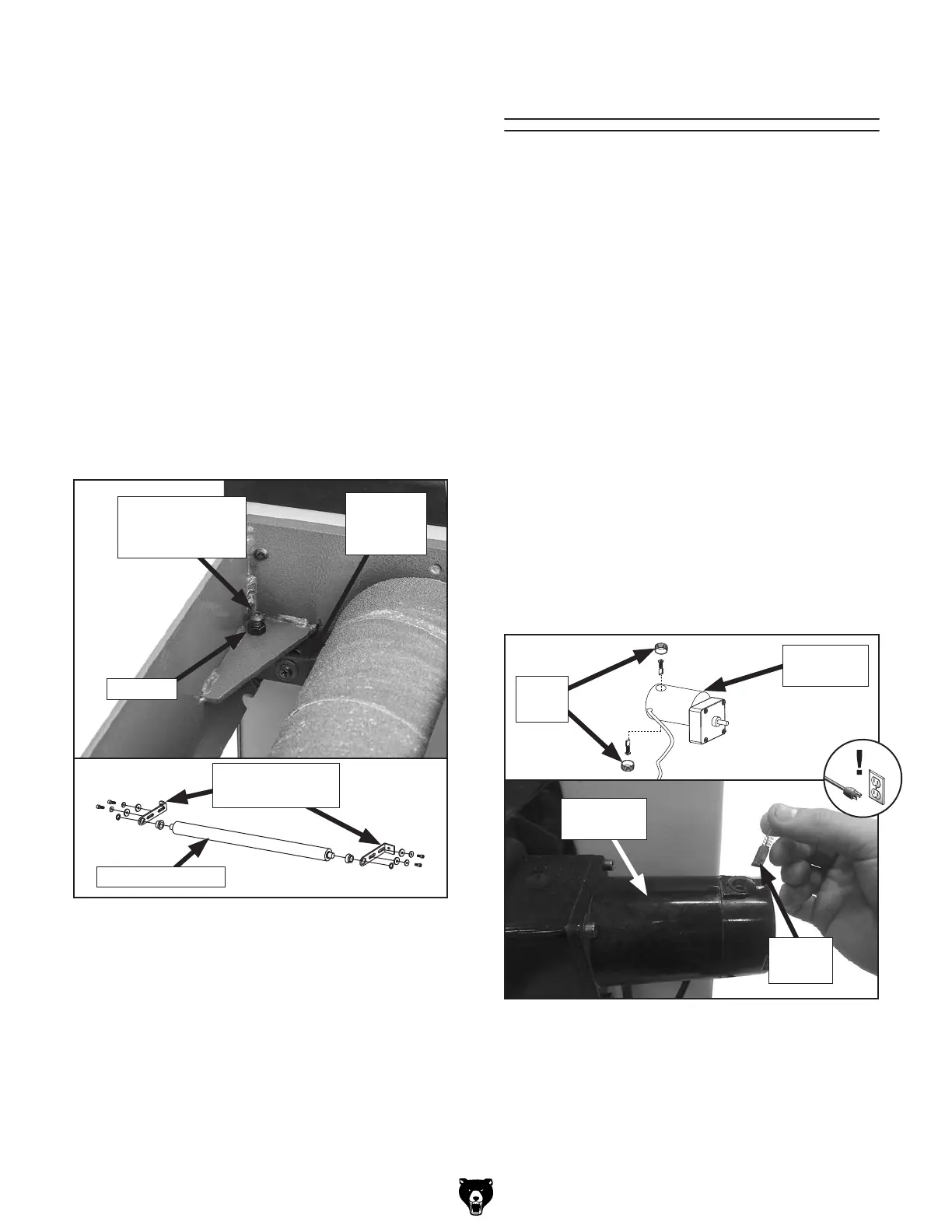

This sander is equipped with a universal motor

that uses two carbon brushes to transmit elec-

trical current inside the motor. These brushes

are considered to be regular "wear items" or

"consumables" that will need to be replaced dur-

ing the life of the motor. The frequency of required

replacement is often related to how much the

motor is used and how hard it is pushed.

Replace the carbon brushes (part number:

P0458Z042-1) at the same time when the motor no

longer reaches full power, or when the brushes mea-

sure less than

1

⁄4" long (new brushes are

5

⁄8" long).

Tools Needed: Qty

Standard Screwdriver #2 ....................................1

To inspect and replace motor brushes:

1. DISCONNECT MACHINE FROM POWER!

2.

Remove brush caps and worn brushes (see

Figure 1) from conveyor belt motor.

Replacing Brushes

3. Replace both motor brushes and install brush

caps.

Figure 1. Location of motor cover cap screws.

Brush

(1 of 2)

Conveyor

Belt Motor

Brush

Caps

Conveyor

Belt Motor

Loading...

Loading...