Model G0817 (Mfd. Since 05/16)

-43-

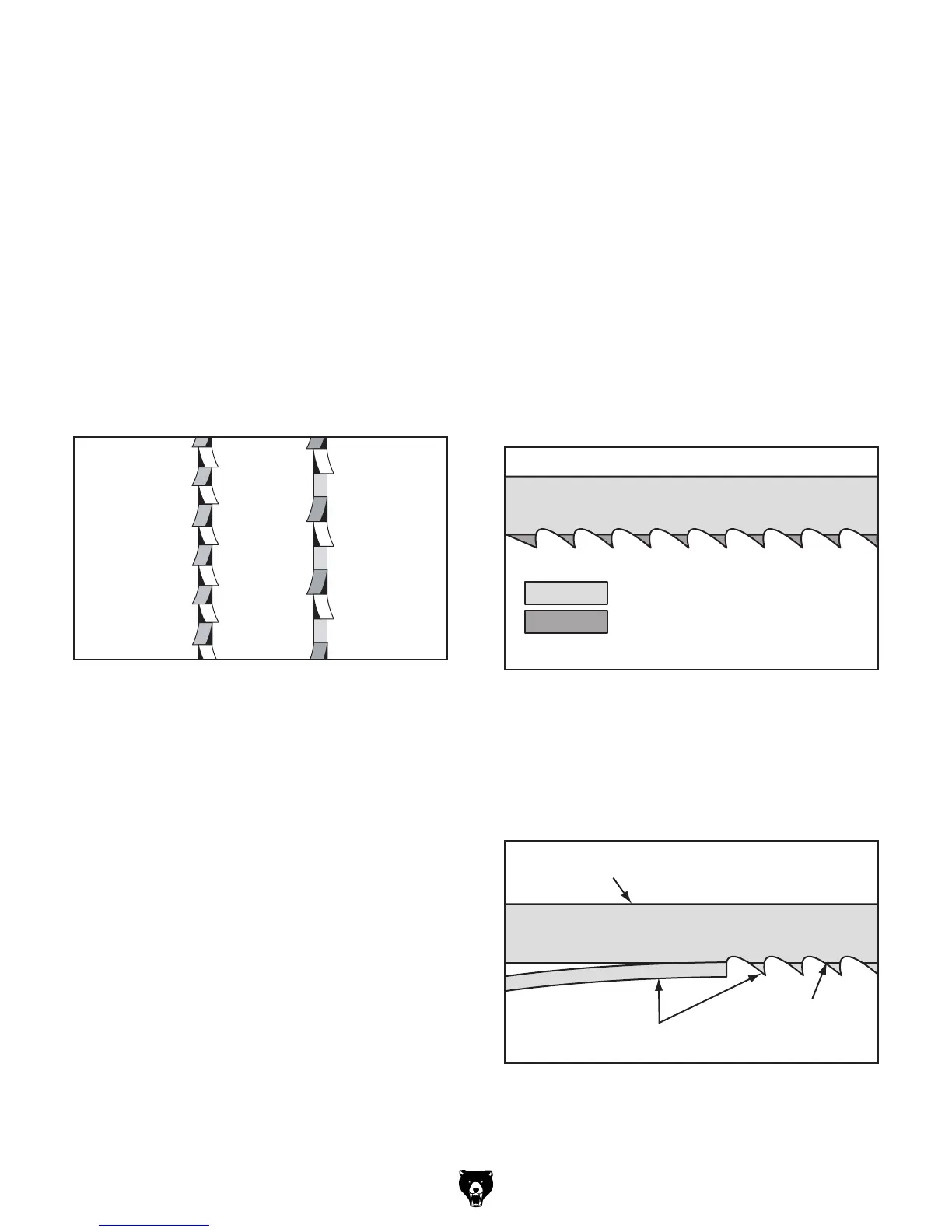

Bi-metal Blade: A strip of high-speed tool steel is

precision welded to a flexible carbon blade, then

teeth are ground into the blade to provide good

edge-holding qualities for blades taking a lot of

abuse (see Figure 70).

Carbon Steel Blade

Weld

High-Speed Steel

Figure 70. Bi-metal blade composition.

Tooth Set

Two common tooth sets for wood bandsaw blades

are alternate and raker. Each different type of

tooth set removes material in a different manner,

leaving cuts with different characteristics (see

Figure 68).

Alternate Raker

Figure 68. Common woodcutting bandsaw blade

tooth sets.

• Alternate: An all-purpose arrangement

where the teeth are bent evenly left and right

of the blade.

• Raker: Three teeth in a recurring group—one

bent left, one bent right, and then one that is

not bent. The raker set is ideal for most con-

tour cuts.

Tooth Pitch

Measured as TPI (teeth per inch), tooth pitch

determines the number of teeth. More teeth per

inch (fine pitch) will cut slower, but smoother; while

fewer teeth per inch (coarse pitch) will cut rougher,

but faster. As a general rule, choose blades that

will have at least three teeth in the material at all

times. Use fine-pitched blades on harder woods

and coarse-pitched blades on softer woods.

Carbon Steel

Carbide Impregnated Steel

Figure 69. Carbide-tooth blade composition.

Blade Material

Bandsaw blades must meet two requirements:

flexibility and hardness. The flexibility of a blade

allows it to travel on the wheel as a band, while

hardness allows the teeth to cut and hold an

edge. Modern materials technology has allowed

bandsaw blades to meet these requirements in

various ways.

Carbon Steel: These blades are differentially

heat treated to provide hard teeth that will hold an

edge, and yet be flexible in the back.

Carbide Tooth: Extremely hard carbide is either

welded onto or impregnated into the carbon steel

blades, providing superior edge-holding charac-

teristics (see Figure 69).

Loading...

Loading...