Model G0817 (Mfd. Since 05/16)

-67-

2. DISCONNECT MACHINE FROM POWER!

3. Remove blade (refer to Changing Blade on

Page 46), remove table, then re-install and

properly tension blade (refer to Tensioning

Blade beginning on Page 28).

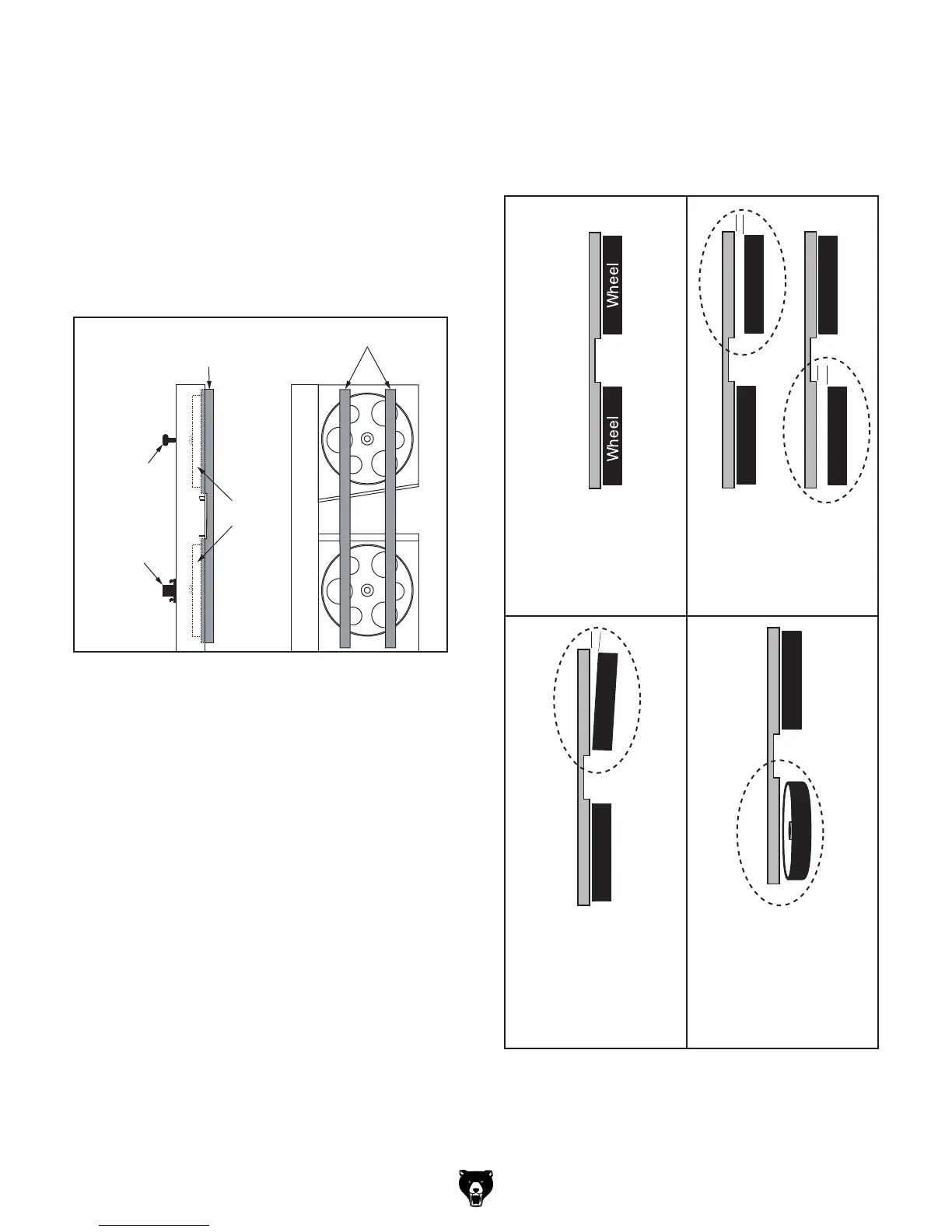

4. Place coplanarity gauge up against both

wheels in positions shown in Figure 107.

Make sure gauge fully extends across rims of

both wheels.

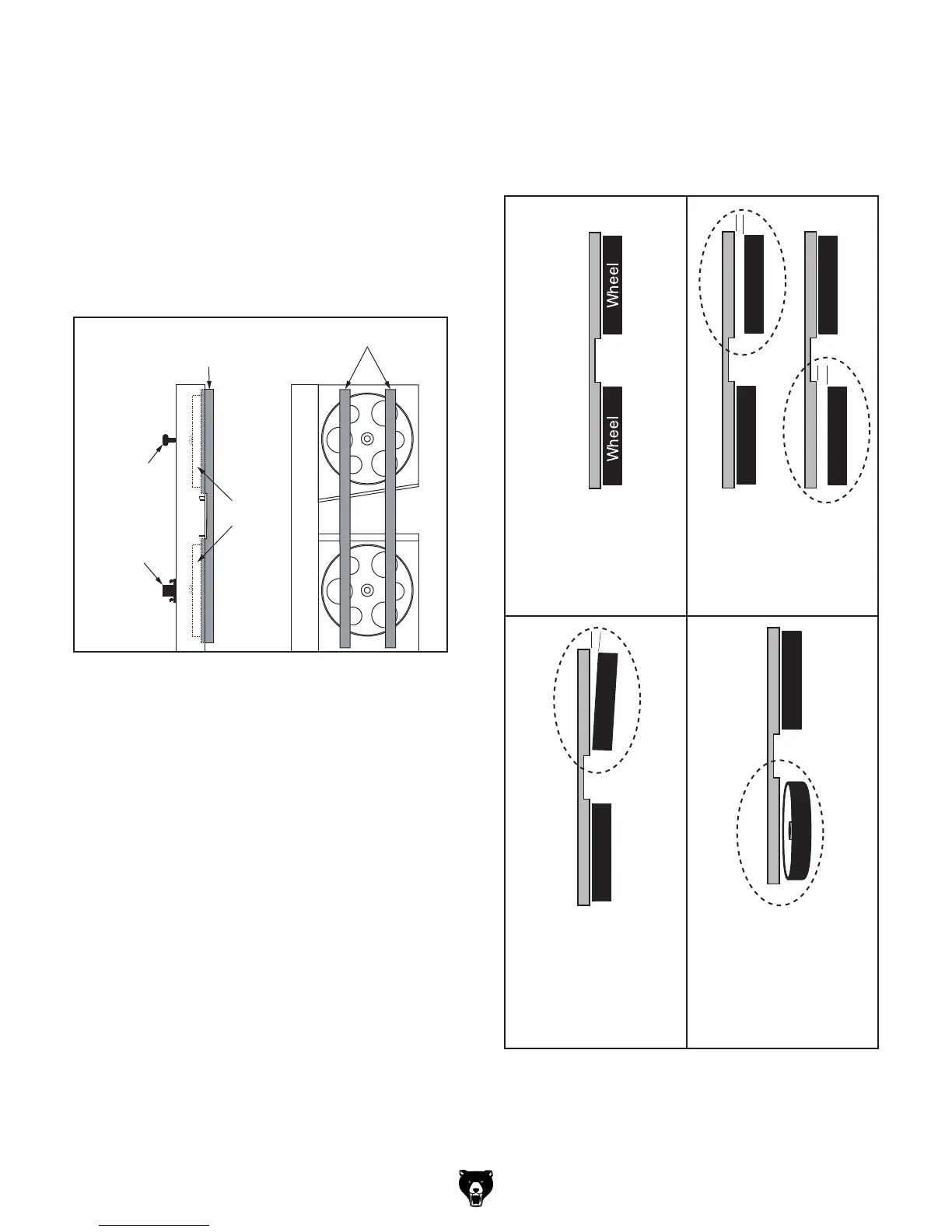

5. Check wheel alignment and adjust tracking

knob to bring both wheels into alignment as

much as possible. If wheels cannot be adjust-

ed coplanar, use Figure 108 to determine

how to proceed with alignment adjustments.

or

Wheels parallel and

aligned: No adjust-

ment needed.

Wheels parallel, but

not coplanar with

each other: Shim

upper or lower wheel

out.

Upper wheel not

vertically aligned with

lower wheel: Use

blade tracking knob

to tilt upper wheel.

Lower wheel not

laterally aligned with

upper wheel: Adjust

rear adjustment set

bolts to tilt lower

wheel left/right.

Coplanarity Gauge

Figure 108. Wheel alignment illustration with

solutions to misalignment problems.

Coplanarity

Gauge

Gauge Positions

Tracking

Knob

Adjustment

Hub

Wheels

Figure 107. Illustration of using coplanarity

gauge to check wheel alignment.

Loading...

Loading...