Model G0817 (Mfd. Since 05/16)

-59-

Tensioning/

Replacing V-Belt

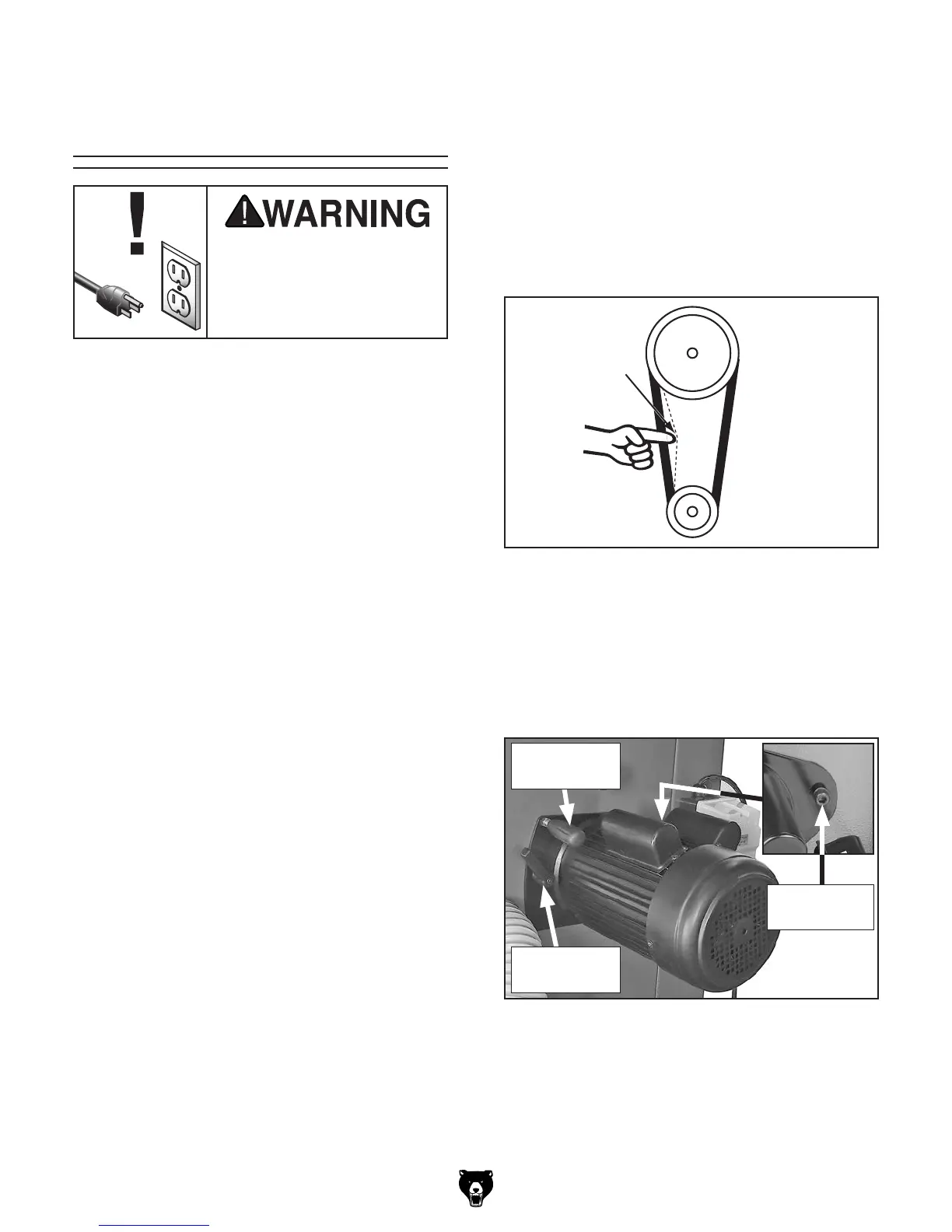

4. Check V-belt tension by applying moderate

pressure between pulleys (see Figure 91).

— If V-belt deflection is approximately

1

⁄4",

belt is correctly tensioned and no adjust-

ment is necessary.

— If deflection is not approximately

1

⁄4", V-belt

is not correctly tensioned. Proceed to

Step 5.

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Tensioning/Replacing V-Belt

To ensure optimum power transmission from the

motor to the blade, the V-belt must be properly

tensioned, and free of cracks, fraying, and wear.

Belt tension and condition should be checked at

least every 3 months—more often if the bandsaw

is used daily.

Tools Needed Qty

Hex Wrench 8mm .............................................. 1

To check/adjust V-belt tension:

1. DISCONNECT MACHINE FROM POWER!

2. Open lower wheel cover.

3. Inspect V-belt; if it is cracked, frayed, or

glazed, replace it (refer to Replacing V-Belt

on Page 60).

Lower Wheel

Pulley

Motor

Pulley

¼" Deflection

Figure 91. V-belt deflection.

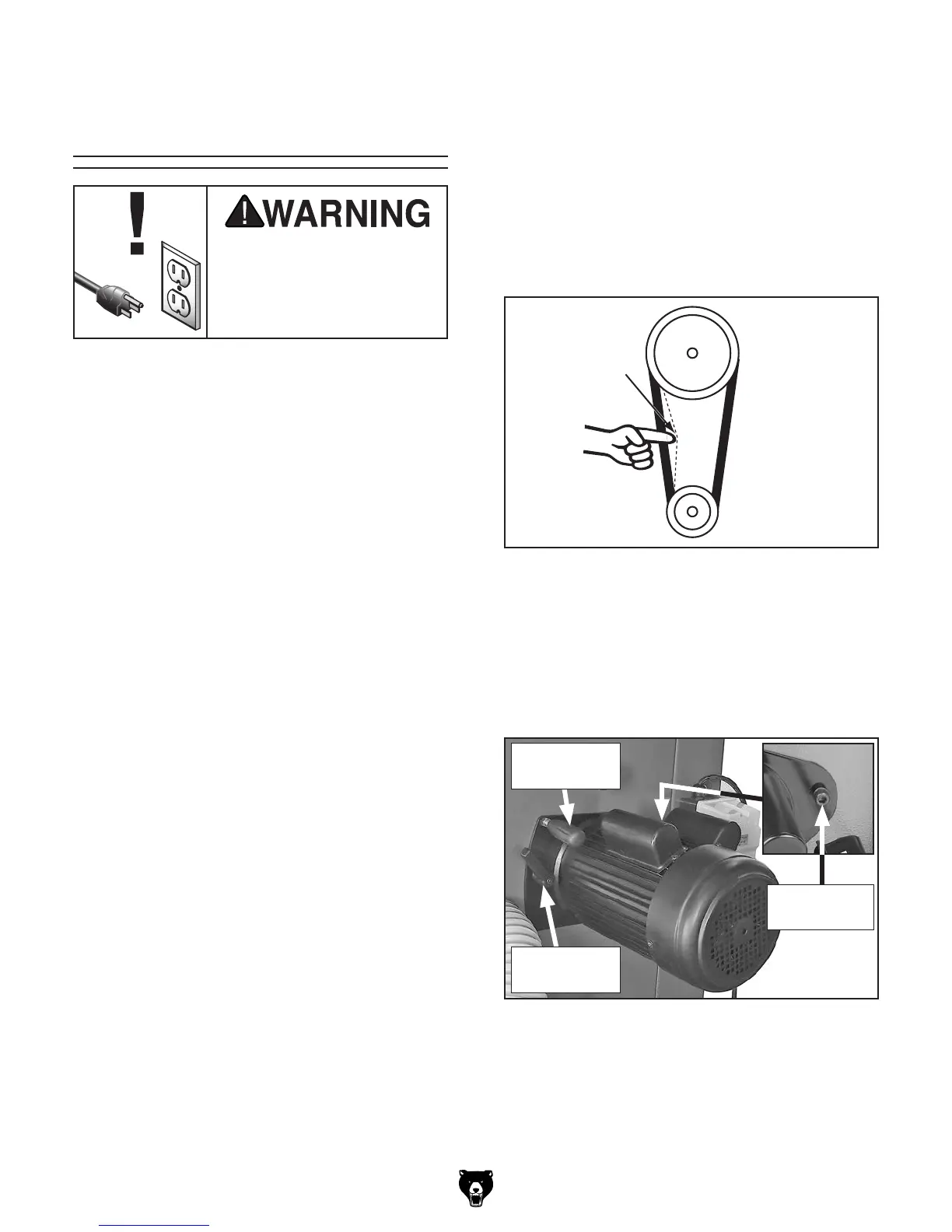

5. Loosen motor mount cap screw and lock

lever (see Figure 92).

6. Use motor mount handle (see Figure 92) to

adjust motor position until V-belt is correctly

tensioned.

7. Retighten motor mount lock lever, then

retighten cap screw to secure adjustment.

Figure 92. Location of V-belt tension controls.

Motor Mount

Cap Screw

Motor Mount

Lock Lever

Motor Mount

Handle

Loading...

Loading...