-56-

Model G0817 (Mfd. Since 05/16)

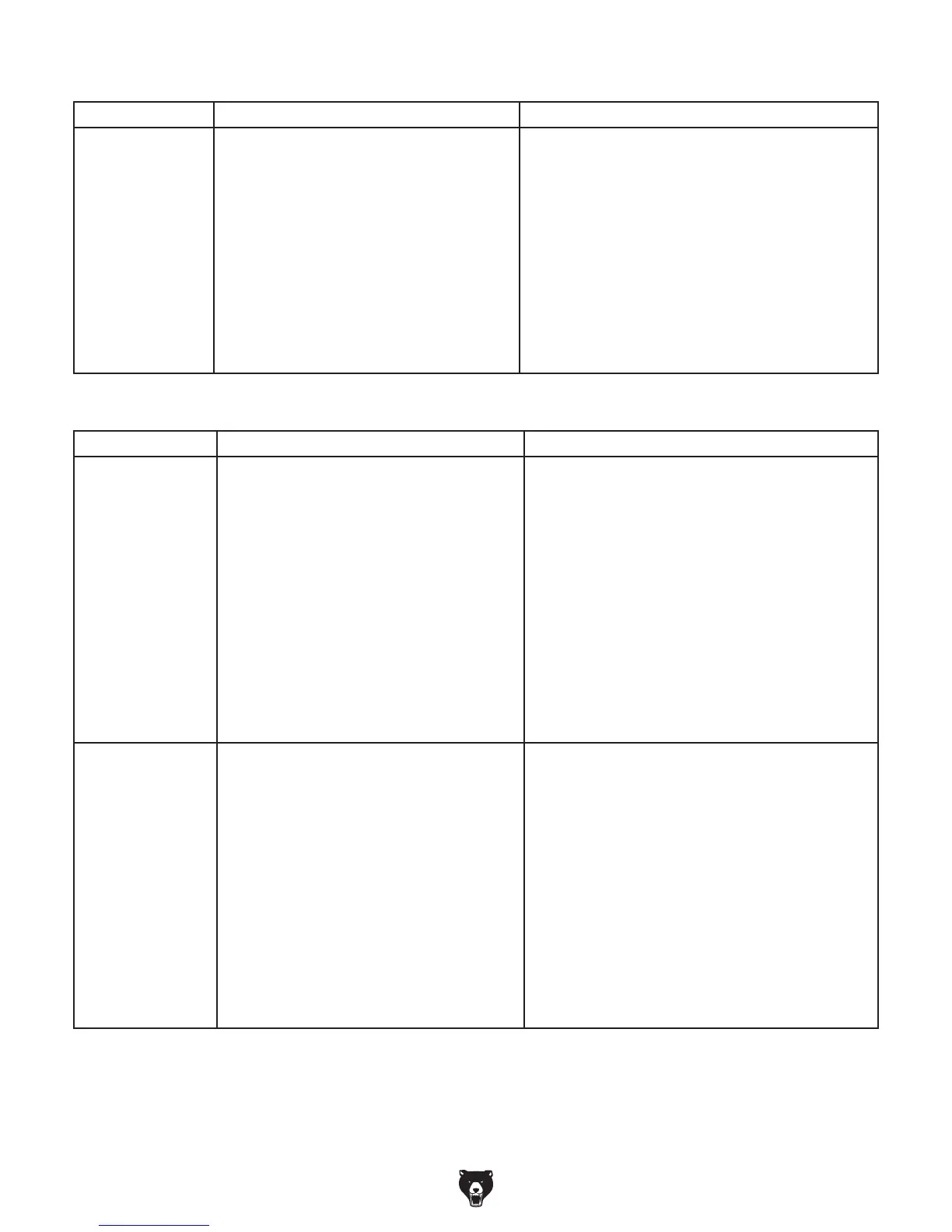

Motor & Electrical (Continued)

Symptom Possible Cause Possible Solution

Machine has

vibration or noisy

operation.

1. Motor or component loose.

2. Blade at fault.

3. V-belt worn or loose.

4. Motor fan rubbing on fan cover.

5. Motor mount loose/broken.

6. Pulley loose.

7. Machine incorrectly mounted.

8. Motor bearings at fault.

9. Centrifugal switch is at fault.

1. Inspect/replace damaged bolts/nuts, and retighten

with thread locking fluid.

2. Replace warped/bent/broken blade; replace/

resharpen dull blade (Page 46).

3. Inspect/replace belt(Page 59).

4. Fix/replace fan cover; replace loose/damaged fan.

5. Tighten/replace.

6. Re-align/replace shaft, pulley set screw, and key.

7. Tighten mounting bolts; relocate/shim machine.

8. Test by rotating shaft; rotational grinding/loose shaft

requires bearing replacement.

9. Replace.

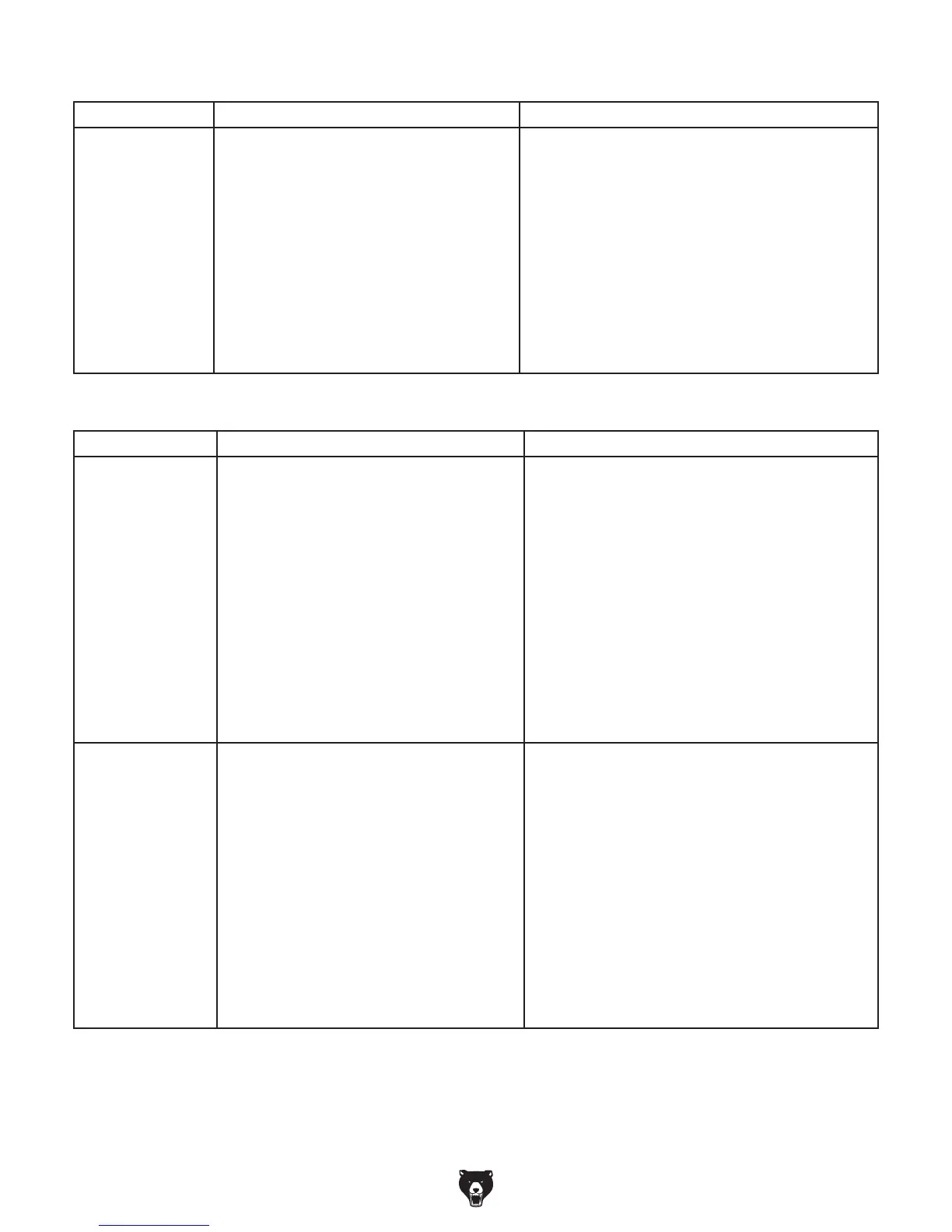

Operating Machine

Symptom Possible Cause Possible Solution

Blade or teeth break/

crack.

1. Blade tension is incorrect.

2. Blade is incorrect for application.

3. Excessive feed rate/pressure.

4. Cutting corners too sharply.

5. Blade is dull/weld at fault.

6. Blade is tracking incorrectly.

7. Blade guides/support bearings not adjusted

properly, allowing guides to hit blade teeth.

8. Wheel tires worn or incorrectly installed.

9. Fence or miter slot out of alignment with

blade.

10. Bad blade-guide bearings.

1. Adjust blade tension (Page 28).

2. Use correct blade for application (Page 41).

3. Reduce feed rate/pressure.

4. Use a wider arc on outside cuts, or use relief cuts

to make tight inside cuts.

5. Replace blade (Page 46).

6. Adjust blade tracking (Page 30).

7. Adjust blade guides/support bearings properly,

so guides cannot contact teeth during operation

(Pages

31–33).

8. Replace or re-install tire.

9. Align table miter slot and fence with blade

(Page 36).

10. Replace blade-guide bearings.

Blade slows,

smokes, shows

overheating or wears

on one side.

1. Blade contacting table insert.

2. Blade guides are worn or misadjusted.

3. Blade installed backwards.

4. Too much side pressure when feeding

workpiece.

5. Wheels are out of alignment.

6. Dull, bell-mouthed, or incorrect blade.

7. Fence not parallel with blade.

8. Table top surface is not parallel or square

to blade.

9. V-belt loose or slipping.

1. Adjust blade guides to eliminate any side pressure

(Page 32). Properly align table (Page 37).

2. Adjust upper blade guides as close to workpiece as

possible.

3. Check blade rotation. Re-install blade if necessary

(Page 46).

4. Feed workpiece straight into blade.

5. Adjust wheels to be coplanar (Page 66).

6. Replace blade (Page 46).

7. Adjust fence parallelism with blade (Page 37).

8. Adjust/shim table/trunnion position until blade and

table are parallel and square (Page 37).

9. Tighten V-belt. Replace if worn or oily. (Page 59).

Loading...

Loading...