Functions

16

SMART Digital S

3

Additional display

Applies to DDA, DDC

The additional display function provides further useful

status information, e.g. the target flow rate as well as

the actual flow rate. The value is shown in the

operation display together with the corresponding

symbol.

Fig. 16 Additional display

The following additional information can be selected:

1) Only DDA-FCM control variant

2) Only DDA-FCM/FC control variant

3) Only DDA pumps

4) Only DDA pumps and DDC-AR control variant

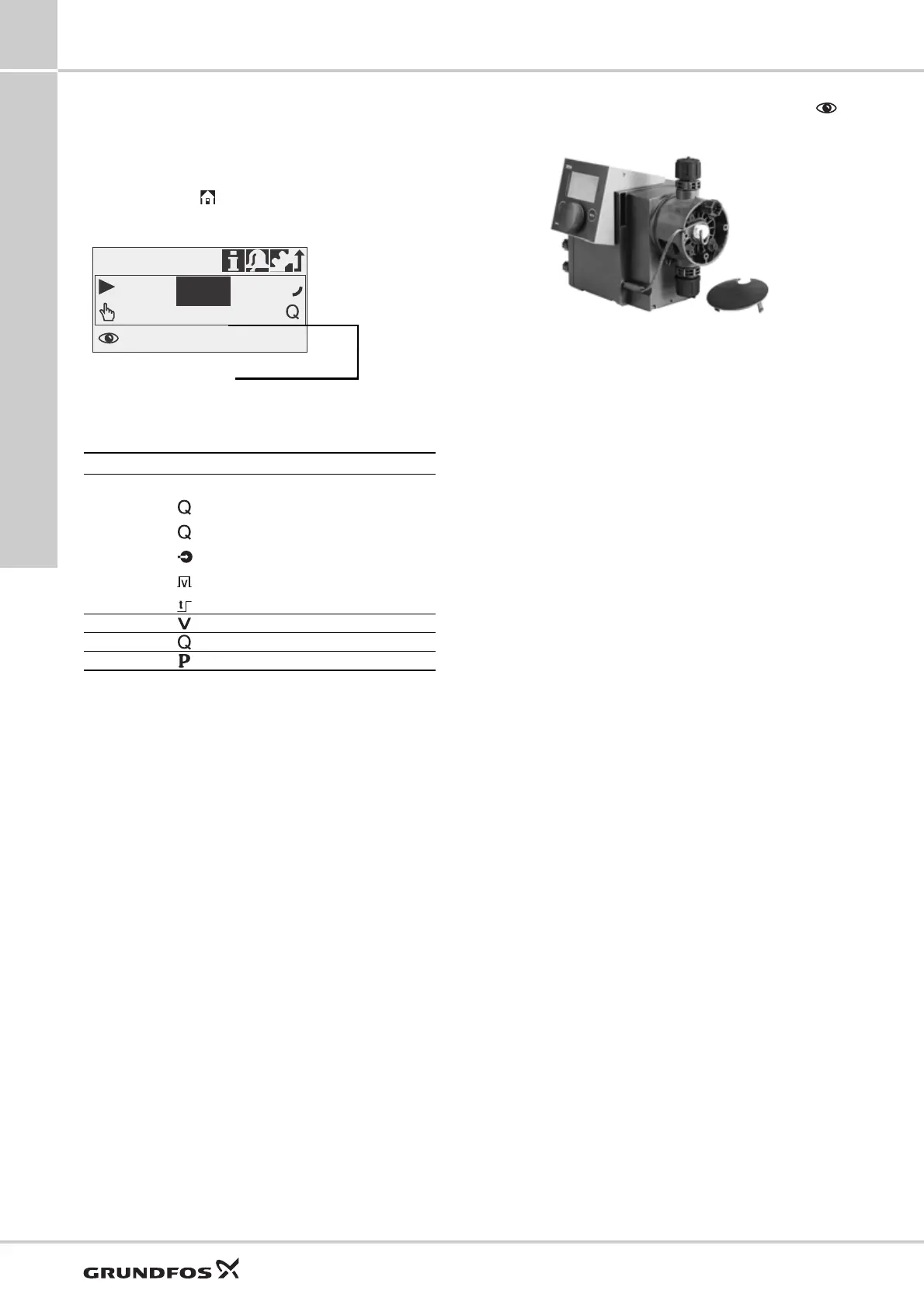

FlowControl

Applies to DDA-FC/FCM

Fig. 17 DDA FlowControl

The pump monitors the dosing process of liquids when

the FlowControl function is activated. Although the

pump is still operating, some influences such as air

bubbles may cause reduced flow rates or even stop

the dosing process. For optimal process safety and

reliability, the activated FlowControl function

immediately detects and displays the following

malfunctions:

• Overpressure

• Discharge line burst

• Air bubbles in the dosing head

• Cavitation at the suction side

• Suction valve leakage

• Discharge valve leakage.

The unique FlowControl is based on an intelligent and

maintenance-free sensor integrated in the dosing

head. During the dosing process, the sensor measures

the actual pressure and sends the measured value to

the microprocessor in the pump. An internal indicator

diagram is generated combining the actual pressure

value with the diaphragm position (stroke length).

With it, the dosing process is monitored, as the

different malfunctions can immediately be detected

due to their specific deviations in the curve.

Compressible air bubbles, for instance, will reduce the

discharge phase and the stroke volume (see fig. 18).

The sensitivity and the delay of the FlowControl

function can be adjusted individually.

FlowControl requires a minimum backpressure of

2 bar. Grundfos recommend an additional

spring-loaded valve (approx. 3 bar) on the discharge

side for dosing low capacities (< 1 l/h) (please see

page 46).

TM04 1633 1810

Settings Description

Default display

Depending on the operation mode:

Actual flow (manual, pulse)

1)

Target flow (pulse)

Input current (analog)

4)

Remaining batch volume (batch, timer)

3)

Time until next batch (timer)

3)

Dosed volume

Total dosed volume (Counters see page 13)

Actual flow

Actually measured flow

1)

Backpressure

Current backpressure in the dosing head

2)

7.49 l/h

Manual

7.50

l/h

Operation

TM04 1641 2617

Loading...

Loading...