Accessories for small dosing pumps up to 60 l/h

43

Accessories for dosing pumps

8

Injection units

Injection units connect the dosing line with the process

line. They ensure a minimum counterpressure of 0.7

bar and avoid backflow of the dosing liquid.

In general, they include:

• Injection pipe. PP, PVC and PVDF versions can be

shortened.

• Spring-loaded non-return valve with Tantal spring.

• Hose connection set: 4/6 mm, 6/9 mm, 6/12 mm,

and 9/12 mm.

• Pipe connection set: threaded, Rp 1/4", internal

thread (stainless steel).

Standard injection units

Dimensions

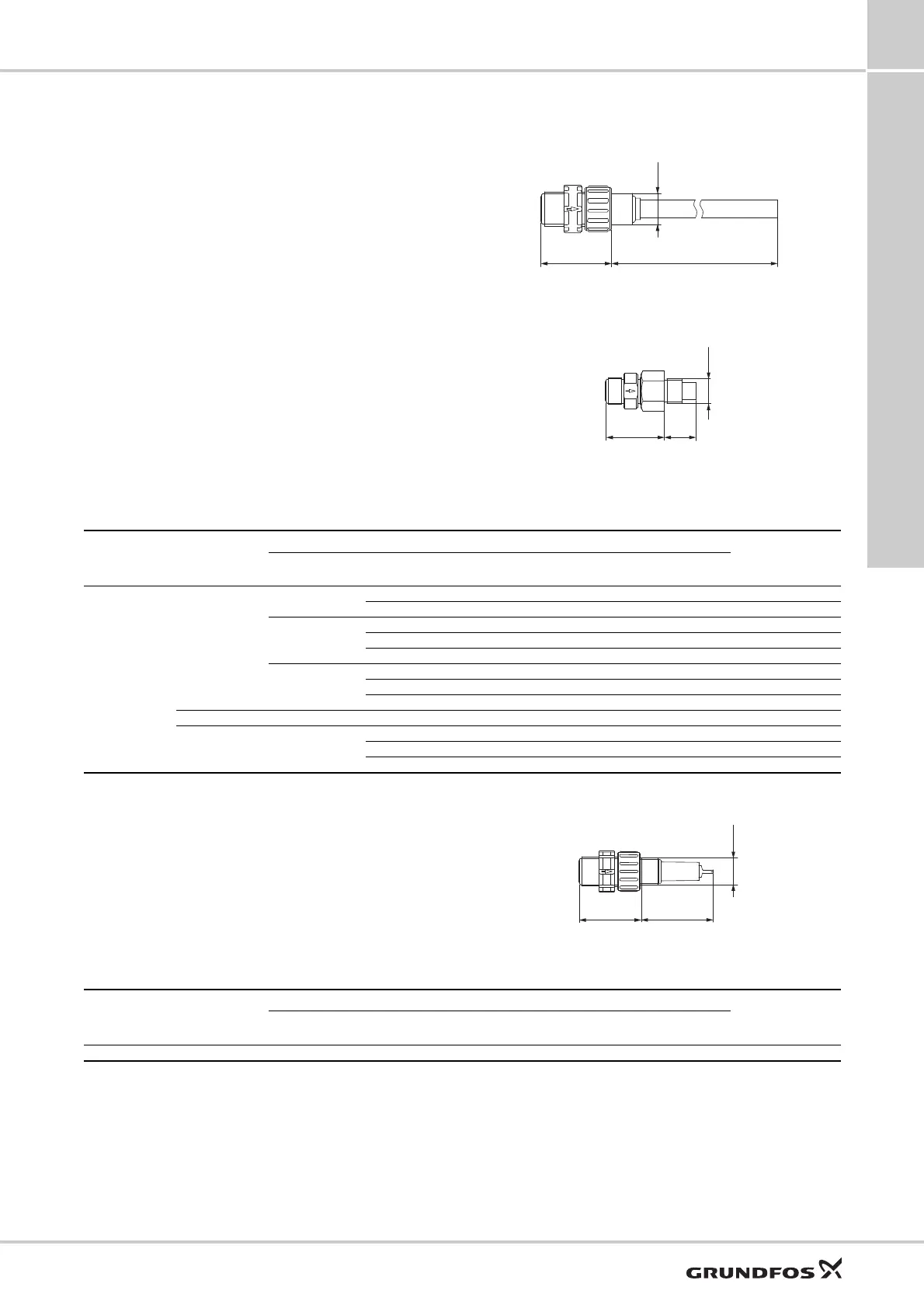

Fig. 36 Standard injection unit, PP, PVC, and PVDF

version

Fig. 37 Standard injection unit, stainless-steel version

Technical data

Injection units with lip valve

Injection units with lip valve are typically used to add

sodium hypochlorite solution to water with a high

carbonate content. The FKM lip prevents

crystallisation and blocking caused by alkali carbonate

reactions at the point of injection.

Dimensions

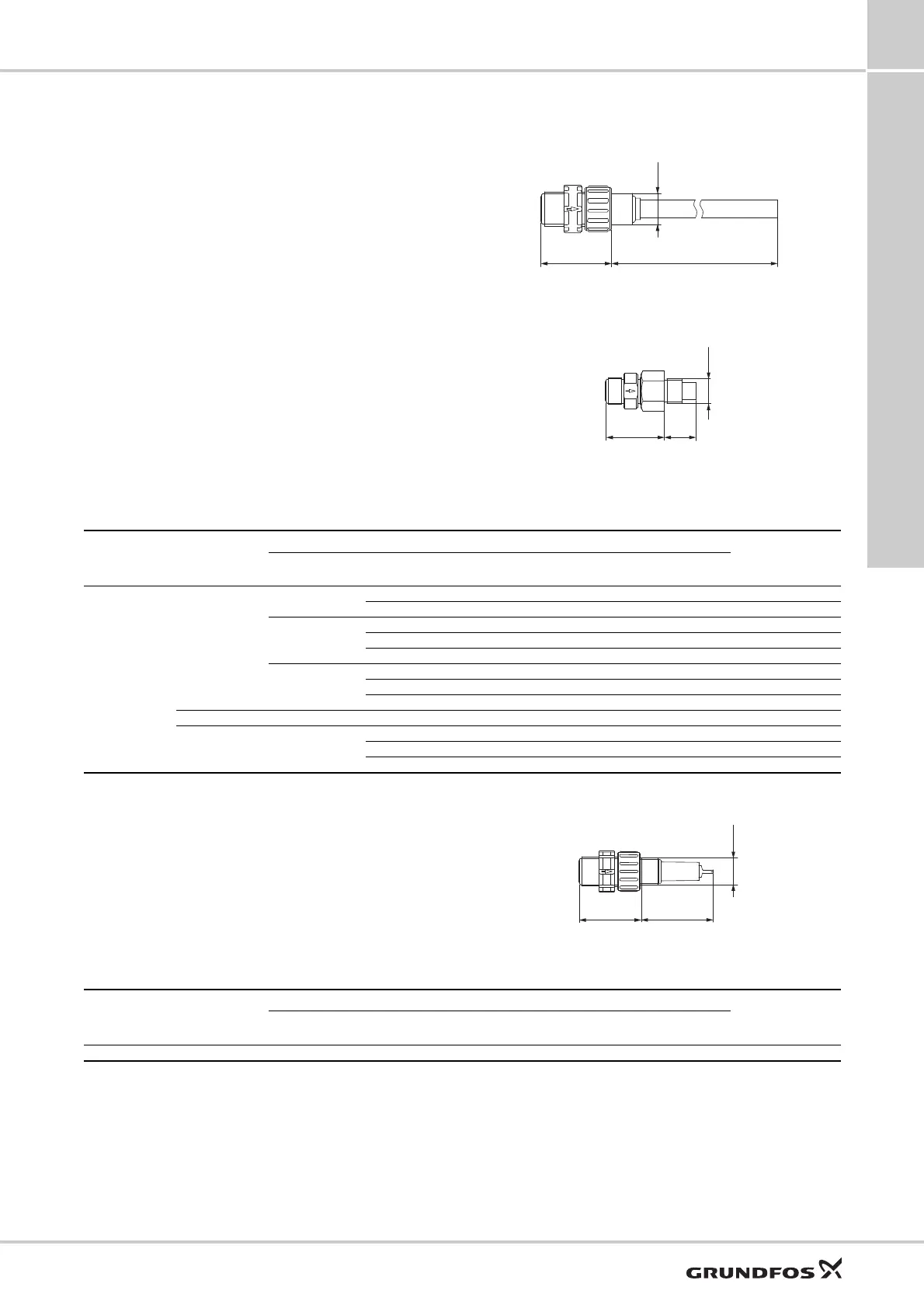

Fig. 38 Injection unit with lip valve

Technical data

TM04 8280 0411TM04 8281 0411

Max. flow rate

[l/h]

Max. pressure

[bar]

Material Dimensions

Product number

Body Gasket Ball

L 1

[mm]

L 2

[mm]

60

16

PP

FKM Ceramic 100 47 95730904

EPDM Ceramic 100 47 95730908

PVC

FKM Ceramic 100 47 95730912

EPDM Ceramic 100 47 95730916

PTFE Ceramic 100 47 95730920

PVDF

FKM Ceramic 100 47 95730924

EPDM Ceramic 100 47 95730928

PTFE Ceramic 100 47 95730932

100 Stainless steel PTFE Stainless steel 27 50 95730936

16 PVC

FKM Ceramic 300 47 95730940

EPDM Ceramic 300 47 95730944

PTFE Ceramic 300 47 95730948

TM04 8282 0411

Max. flow rate

[l/h]

Max. pressure

[bar]

Material Dimensions

Product number

Body Gasket Ball

L 1

[mm]

L 2

[mm]

60 16 PVC FKM Ceramic 55 59 95730964

Loading...

Loading...