Construction

22

SMART Digital S

4

4. Construction

DDA and DDC

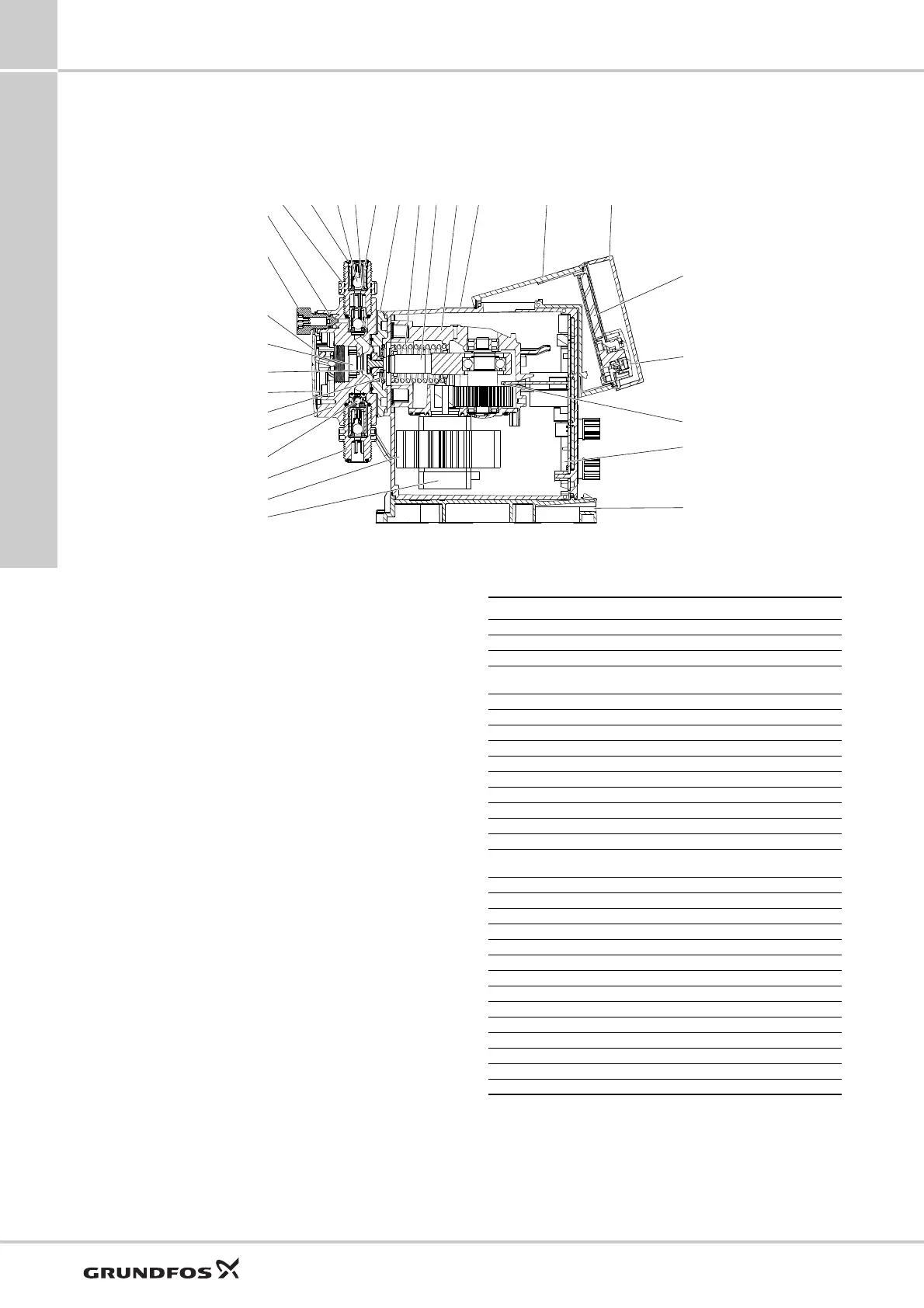

Fig. 19 Sectional drawing, DDA

Construction

The DDA and DDC pumps are motor-driven diaphragm

dosing pumps consisting of the following main parts:

Dosing head: Patented design with a minimum of

clearance space optimised for degassing liquids.

With integrated deaeration valve for priming and

venting complete with connection for a 4/6 mm or 0.17"

x 1/4" tubing. DDA-FCM/FC pumps have an integrated

pressure sensor in the dosing head.

Valves: Double-ball discharge and suction valve*

design for less clearance space - optimised for

degassing liquids. Spring-loaded valves for higher

viscosities are available as an option.

Connections: Robust and easy-to-use connection

packages for various sizes of tubing or pipes.

Diaphragm: Full PTFE diaphragm designed for long

life and universal chemical resistance.

Flange: With separation chamber, safety diaphragm

and drain hole.

Drive unit: Positive return crank with patented

noiseless spur gear drive, energy recovery spring for

high efficiency (only DDA), stepper motor, all mounted

in a robust gear housing.

Control cube: Containing operation electronics with

display, keys, click-wheel and protective cover.

Housing: Containing drive unit and power electronics

with robust signal sockets. The housing can be clicked

on the mounting plate.

Material specification

TM04 1533 1010

1

2

3

4

5

6

7

8

9

13

14

15 16

17

23

24

25

26

27

28

29

18 19

20

21

22

10

11

12

Pos. Description Material options

1 Stepper motor -

2 Cooling element** Aluminium

3 Suction valve, complete*** -

4 Valve ball, DN 4*

Ceramic Al

2

O

3

99.5 %,

SS 1.4401

5 Dosing head PP, PVC, PVDF, SS 1.4435

6 Safety diaphragm EPDM

7 Dosing head screw SS 1.4301

8 Diaphragm full PTFE

9 Pressure sensor -

10 Dosing head cover PP, SS 1.4301

11 Deaeration valve PP, PVC, PVDF

12 Deaeration valve O-ring EPDM/FKM

13 Discharge valve, complete*** -

14 Discharge valve O-ring EPDM, FKM, PTFE

15 Discharge valve ball, DN 8

Ceramic Al

2

O

3

99.5 %,

SS 1.4401

16 Discharge valve seat EPDM, FKM, PTFE

17 Discharge valve ball cage PP, PVC, PVDF, SS 1.4435

18 Flange PPO/PS 20 % gf

19 Energy recovery spring** EN 10270-2/VD SiCr

20 Connecting rod PA 6.6 30 % gf

21 Gear box PPO/PS 20 % gf

22 Housing PPO/PS 20 % gf

23 Control cube PPO/PS 20 % gf

24 Display cover PC

25 Operation PCB -

26 Click wheel PPO/PS 20 % gf

27 Hall sensor -

28 Power PCB -

29 Mounting plate PPO/PS 20 % gf

* Only for pumps up to 7.5 l/h with standard valves

** Only for DDA

*** Pump can be supplied with spring-loaded valves (Material: Tantal)

Loading...

Loading...