Installation

25

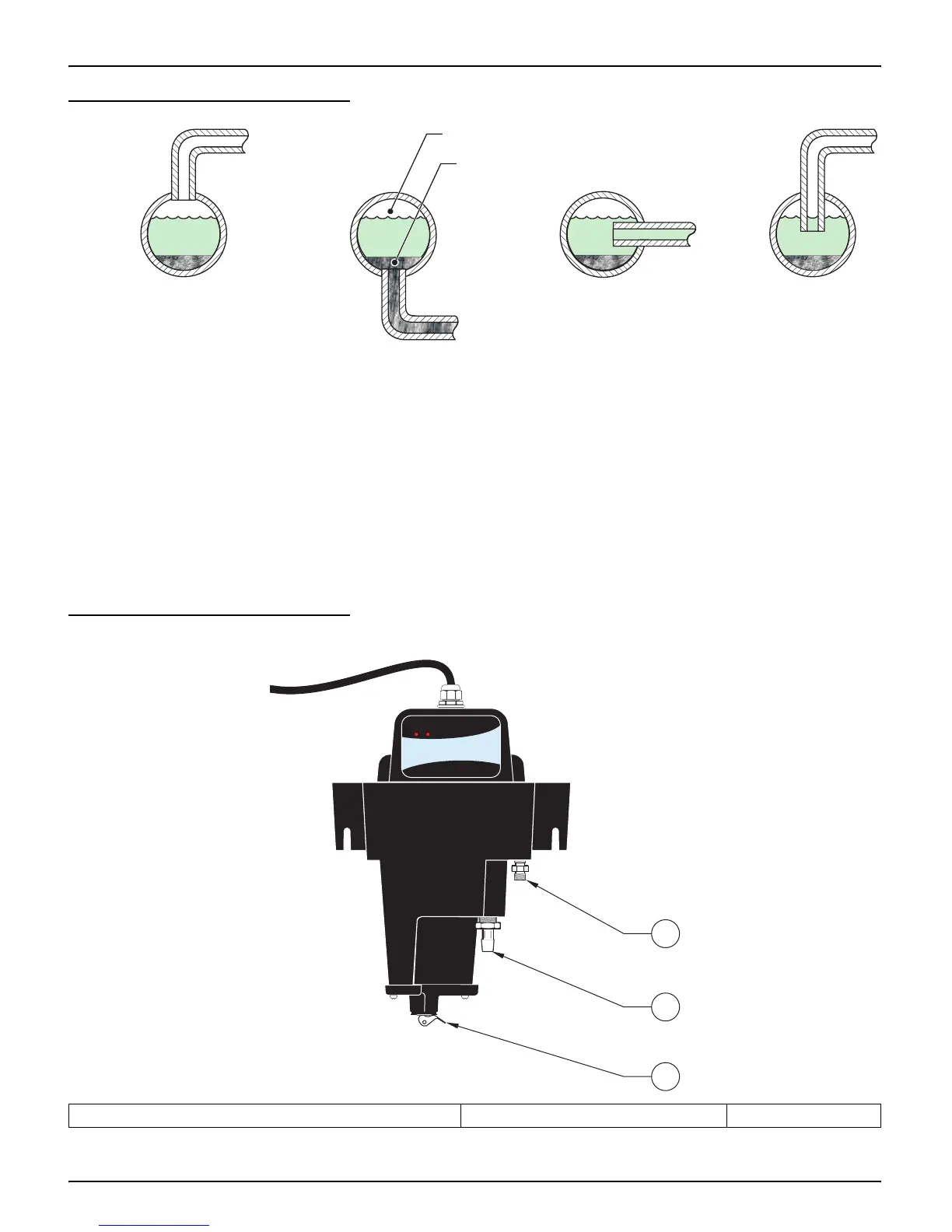

Figure 24 Sampling Techniques

3.8 Sample Connections

Sample inlet and drain connections are made on the turbidimeter body. The

sample inlet fitting installed in the body is a ¼-inch NPT

x ¼-inch compression

fitting. One additional fitting supplied with the instrument is a ½-inch NPT-to-hose

fitting for use with ½-inch ID flexible plastic tubing on the drain.

Note: For samples with high solids

content (high turbidity), operate at

the highest flow rate possible. For

samples with low solids content (low

expected turbidity), operate at a low

flow rate (200–300 mL/min).

The required flow rate is 200 to 750 mL/minute (4.0 to 11.9 gal/hour). Flow rate

into the turbidimeter may be controlled with a flow restriction device on the inlet

line. Flow rates below 200 mL/min will reduce response time and cause

inaccurate readings. Flow rates above 750 mL/min will cause the turbidimeter to

overflow, indicating the flow rate is too high.

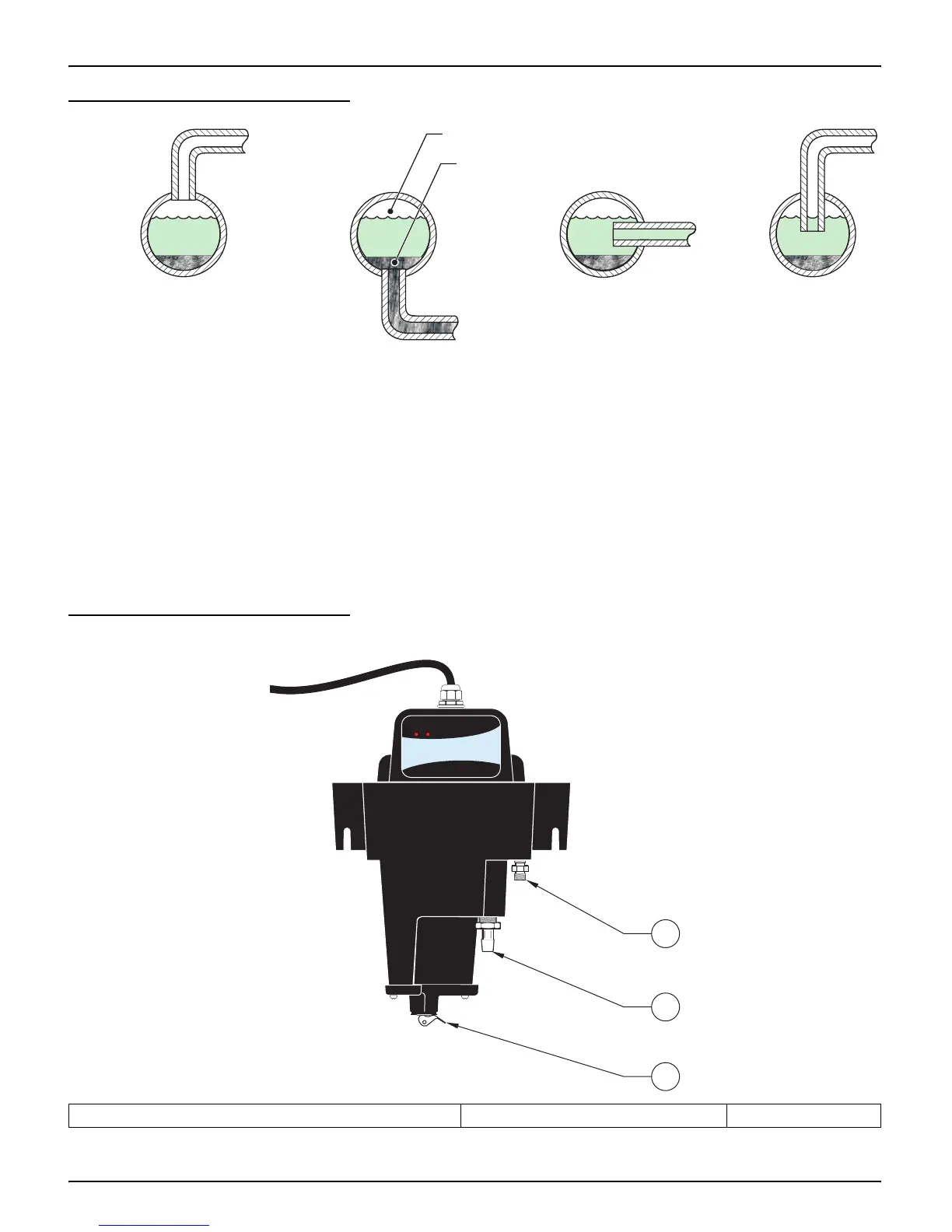

Figure 25 Sample Connections

Poor

Sediment (Typical)

Air (Typical)

Poor

Good Best

1. Sample Inlet, ¼-28 NPT x ¼-inch Compression fitting 2. Drain, ½-inch NPT fitting 3. Service Drain

POWER

STATUS

1

2

3

Loading...

Loading...